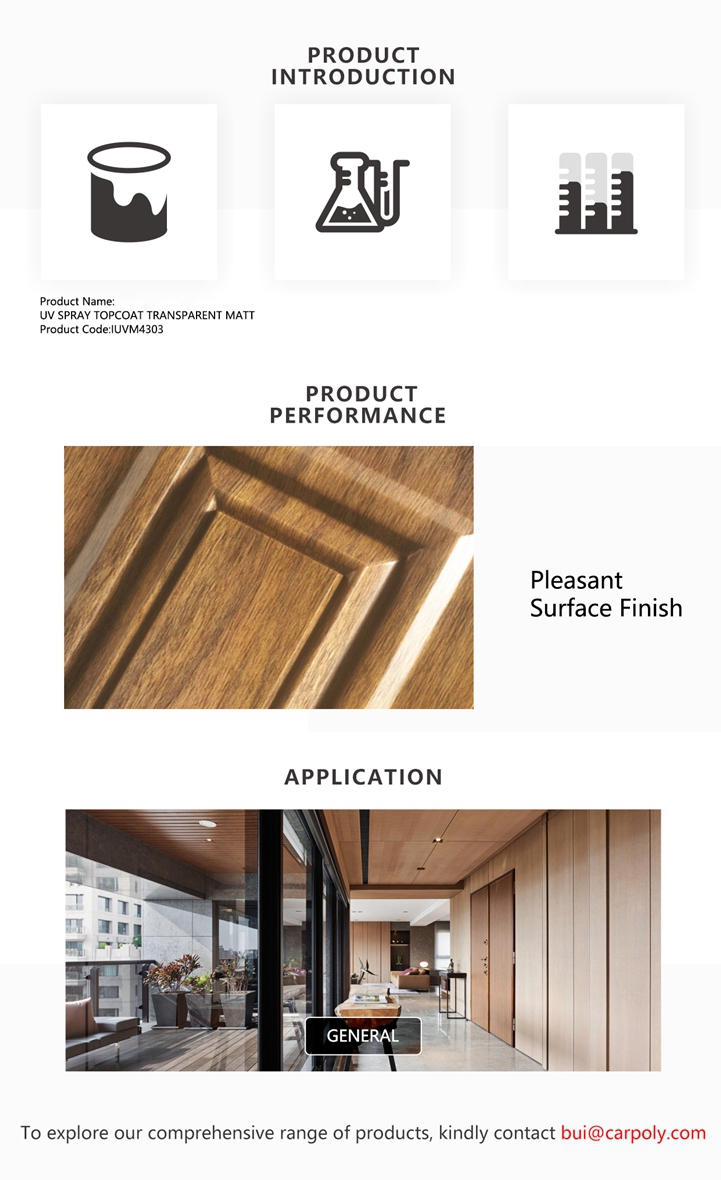

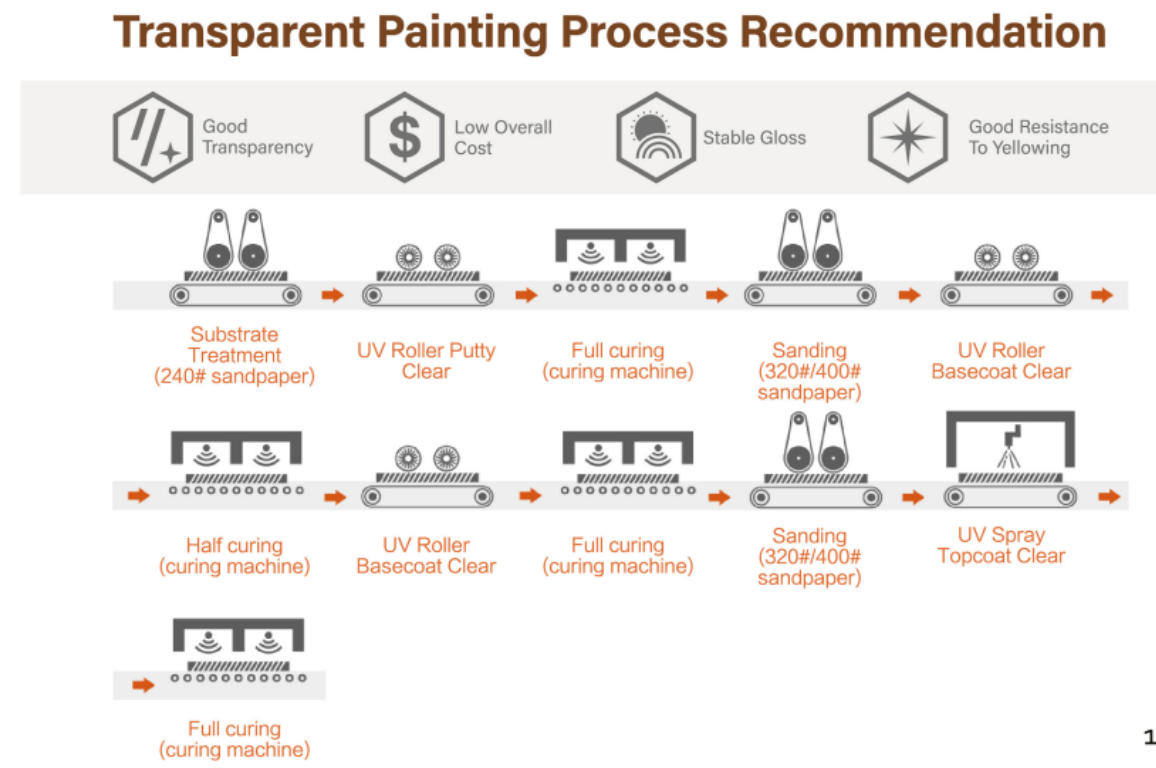

Ultraviolet Curing Spray Topcoat Transparent Matt

- Supplier:

Carpoly Chemical Group Co., Ltd.

Carpoly Chemical Group Co., Ltd.

- Loading Port:

- GUANGZHOU

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 kg

- Supply Capability:

- 650000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

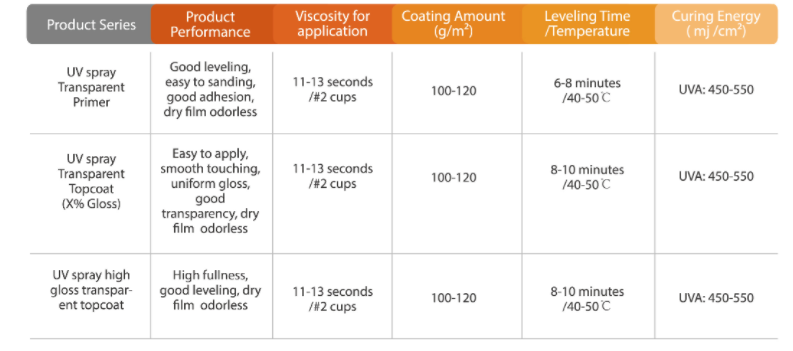

Carpoly Ultraviolet curing coatings have the advantages of low volatile organic compounds(VOC) emission,little pollution to the environment, high curing speed,energy saving, good performance of cured products, suitable for high-speed automatic production and so on.

- Q: My carpet is dirty, the carpet is chemical fiber, I want it dyed gray, there is no such pigments, where can I buy? Requirements as far as possible not fade, not finished after the hair hard, it is best to spray water spray.

- I long-term supply of the following varieties: direct dyes. Acid dyes. Acidic dyes. Acid media dyes. Neutral dyes. Sulfide dyes. Reducing dyes. Basic dyes. Reactive dyes. Cationic dyes. Disperse dyes. Printing chemicals. Printing with nickel mesh, dyes intermediates. Fur chemical dyes. Leather chemical dyes. Chemical additives. Resins. Ink. Organic chemical pigments. Imported. Domestic waste dyes can be recycled. Companies seeking business and customers to develop , Cast a better future .-- Thank you !!

- Q: IPHONE4 lithium polymer battery charge for the first time to charge how long

- Iphone to buy home when it is already full of electricity, their own charge about 4 hours or so can be full (and in the case of standby)

- Q: Enamel paint

- Enamel paint taste good for 1 million dollars jack.

- Q: Use talk about. Which is longer.

- Preservation time point of view, the ink is easy to save, you can not long-term solid color, because the animal glue in the dry insoluble in cold water, so there is a certain moisture resistance. Other types of pigments, water-based pigments such as watercolor gouache, dry soluble in cold water, so the poor resistance to moisture, oil painting itself is very difficult to save, the pigment layer and the base of the base layer are easy to problems, Mao will be attached. Propylene pigment is a modifier chemical instability, short life itself, although dry and insoluble in water, but the same damp expansion, easy to peel off, not reliable. In contrast, the ink is the most reliable black colorant on the paper and silk surface, but it is best to use the now polished ink, the quality of the bottled ink is less, the firmness of the ink is even worse, so the ink is not Overnight, bottled ink do not put too long, pour out and do not spend the night.

- Q: can a paint sprayer be used for indoor painting/latex paint

- sure! just no what u r doing thats all.

- Q: Ms Paint

- Its just a basic graphic editing tool thrown in with Windows, so that people could mess around with pictures. Whilst it obviously doesn't compete with professional graphics software, it provides a distraction, and a way of saving bmps and jpgs of screen dumps with no additional software.

- Q: what technique is the best for splatter painting???

- step one: dip paint brush in paint step 2: take brush out of paint step 3: bring paint brush over head and back step 4: with a lot of force, hold brush and thrust forward step 5: admire outcome variations of step 3 can be used. under hand, side arm etc.. be sure to wear clothes that can be ruined

- Q: I have this nice desk, but is is fake wood and I would like to paint it. What do I do so I can paint it? Thanks in advance!

- You can paint on anything, but you need to make sure it is clean and it is also a good idea to sand it with 200 grit sanding paper to make sure the paint will hold. Then you can paint it with a roller brush or spray paint it. You can paint primer if you really want to but you could also go without.

- Q: What is the difference between the paint and the paint?

- Water is a water thinner, no organic solvent coating, benzene, toluene, xylene, formaldehyde, free TDI toxic heavy metals, non-toxic non-irritating odor, harmless to the human body, do not pollute the environment, Paint is a kind of can be firmly covered in the surface of the object, from the protection, decoration, signs and other special purposes of the paint, Chemical mixture coating. Their difference is that the paint is more environmentally friendly than paint, no nasal taste, harmless to the human body. Morning sun water paint in this area to do more time, you can understand.

- Q: How to use the pigment three primary colors (red, yellow, blue) out of brown and brown?

- Red, yellow, blue plus a little orange

Send your message to us

Ultraviolet Curing Spray Topcoat Transparent Matt

- Supplier:

Carpoly Chemical Group Co., Ltd.

Carpoly Chemical Group Co., Ltd.

- Loading Port:

- GUANGZHOU

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 kg

- Supply Capability:

- 650000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches