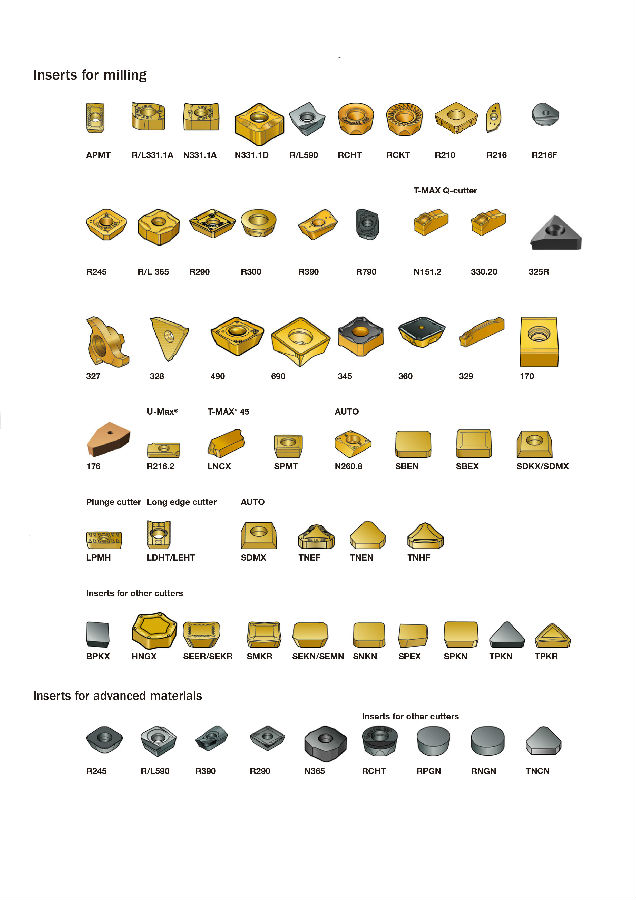

tungsten carbide inserts for cutting tool

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Information

- pure tungsten carbide material, recycling material is available

- Size of the inserts:OD limited crabide to 400 mm,thickness above 2mm

- Manufacturering carbide products including TC ball,bar material,wortle,strips,tips,dies,milling cutters,scraper blades,rods,inserts and so on.

- Factory price,manufacturing irregular shape according to your inserts' drawing

Packaging

1,soft foam to prevent the surface being scratched in one small carboard boxes, several small boxes in one larger hard carboard with fills to avoid a slope, besides hard carboard is easy to load and transport

2, we can also arrange packaging according to your special requirements or discuss

3,product code on cardboards instead of any company information such as logo to keep deal information secret and beneficial to customs clearance

Shipping

There are three ways to be choose, as follows:

- International Express: UPS,TNT,DHL

- Port transportation: all ports

- We delivery products according to customer’s requirements and paid by buyer after the destination confirmation

- take insurance for the goods according to contract

Our Service

- ISO , BV certificate and sound testing equipment to assure the quality

- Professional advice for the application problems, we accept return of goods with quality problems or discuss

- Survey Email of products usage will be sent timely to listen your feedback,our aim is trying to make everyone of our customers satified!

- Q: The lower corners of the car blade allow the tools to be worn down

- Tool durability (tool life) is an important parameter to measure the cutting performance of tool material, cutting machinability of workpiece materials and the reasonable parameters of tool geometry parameters. If you use the tool's durability (tool life) times the cutting time, it is the total life of the tool.

- Q: What does the color stand behind the car knife?

- You're talking about CNC cutting tools, and the tools on the car don't seem to be!

- Q: The main difference between the thread and the outside thread? Is it mainly on the car knife?

- The thread needs to be drilled first and then applied to the inner surface with the tool.I hope my answer will help you.

- Q: How to use a car knife properly in machine processing?

- 1) cold hard. It has a high hardness in normal temperature, which is the wearability of the tool. 2) red and hard. The hardness required for cutting at high temperature is called "red hot hardness". 3) resilience. The cutting part of the lathe is subjected to the strength and hardness of vibration and shock load.

- Q: The welding method of the lathe tool

- There are two types of welding methods for lathe knives; One is the brazing copper wire and borax. The second is to use high frequency welding

- Q: High speed steel tool for high-speed cutting

- There is no such thing as a "inevitable" thing. As long as you're cool enough and cut deep, there's nothing you can't do.

- Q: What's the difference between a car knife and a milling cutter

- Installed on the lathe tool, used to cut metal cutting tools. Welding tool, is on the common steel bar, with milling cutter machining carbide insert the corresponding incision, borax and copper solder brazing.

- Q: What kind of tool can you use

- Can use the big spiral Angle cutter (cylindrical milling cutter, end mill), spiral Angle b increased from 20 ° to 45 ° (designed.the gn = 5 °), the tool life can be increased by more than 2 times, because work at the moment of the milling cutter rake Angle g0e by 11 ° increased to more than 27 °, milling fast. But b value should not be again big, especially the vertical milling cutter with b 35 ° or less advisable, so as to avoid weakening the blade. The stainless steel tube or thin wall parts are made of corrugated edge milling cutter, the cutting is light, the vibration is small, the chip is fragile and the workpiece is not deformed. The stainless steel with carbide end milling cutter, indexable milling cutter and milling cutter can achieve good results.

- Q: How do you grind the diamond tool?

- The grinding of diamond is made on cast-iron abrasive disk. The diameter of the grinding disk is about 300mm, and the shape, size and proportion of the pore in the material tissue are optimized by the optimized grinding diamond. The surface of the grinding disc is covered with diamond grinding powder, which can be small in size from 1 to 40. Coarse particles of the diamond powder with high grinding rate, but the poor quality of grinding, the commonly used while so coarse grinding coarse powder, and fine grinding, the use of the size less than 1 (including m fine powder.

- Q: Which direction does the transverse orientation of the lathe point in?

- Horizontal is the direction of the head of the bed.I hope my answer will help you.

Send your message to us

tungsten carbide inserts for cutting tool

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords