Tungsten Carbide Composite Roll for High Speed Wire Mill

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Tungsten Carbide Roll Description:

The disadvantage of cemented carbide (tungsten carbide) rolls: brittleness, small impact toughness. Generally, the impact toughness is 1/3 of chilled steel, 1/10 of annealed steel. Therefore, using these rolls can not bump against. Quick heating and cooling is also harmful for these material

high-performance rolls for hot rolling mills

made exclusively from virgin materials

wide variety of standard grades

state-of-the-art materials from element six, one of the leading manufacturers worldwide

available for nearly every rolling application

excellent surface finish of the rolled product

machining service and training available

OUR BRAN INCLUDED THE YGR SERIES! YOU NEED MORE, JUST CONTACT US FREELY.

Main Features of the Tungsten Carbide Rolls:

- best wear-resistance

- High thermal conductance

- better moderate resistance

- good toughness

- good resistance for thermal cracking

- Used for finishing and prefinishing stands of high speed wire-rod rolling mill,finishing stands of bar rolling mill, sizing stands of high speed wire-rod rolling mill

- ISO9001:2008 Certification

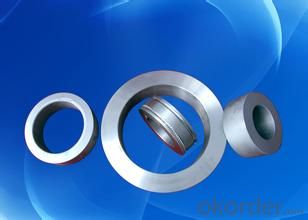

Tungsten Carbide Roll Images:

FAQ:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: What is our advantage?

A: Top Cemented Carbide has extensive business experience, Fast delivery and high quality.

- Q: How to strengthen the shock resistance of powder metallurgy metal parts?

- Sintering technology should be excellent, if possible, hot isostatic pressing (low pressure) sintering furnace sintering, the stress is small, uniform structure.

- Q: Process flow of powder metallurgy parts plating

- The formation of powder metallurgy electroplating process is mainly because the powder metallurgy parts is the use of metal powder pressing and sintering, thus containing oil and porous, which requires the electroplating process in powder metallurgy, electroplating processing, all kinds of solution into the pores of the coating has great impact on the quality of.

- Q: What kind of imported metallurgical machinery parts do steel mills need to rely on?

- Domestic is not impossible and foreign than, the key is that performance is not as good as abroad, especially in our domestic metallurgical enterprises equipment, production processes, are lagging behind than in other countries.

- Q: Why are powder metallurgy parts generally small?

- Although this part has higher hardness and wear resistance, but as a shaft parts of the fatigue resistance can not be guaranteed, a small defect can lead to damage.

- Q: How can make powder metallurgy machinery fittings have hardness, toughness?

- The above methods can be used separately, without regard to this factor, can also be used all.

- Q: What is the manufacture of powder metallurgy machinery parts?

- Powder metallurgy includes milling and products. Among them, the milling process is mainly metallurgy, and literal agreement. And powder metallurgy products are often far beyond the scope of materials and metallurgy, often interdisciplinary (materials and metallurgy, machinery and mechanics, etc.) technology.

- Q: Why does the aspect ratio of powder metallurgy machine parts need to be controlled?

- Mainly related to the mold, or die punches easily damaged, affecting the die life.

- Q: What are the types of powder metallurgy machinery parts?

- Powder metallurgy parts can not be subdivided into different types, because different metal, nonmetal and other additives are added in the matrix material to achieve different effects, which need to be decided according to different performance requirements.

- Q: What kind of high temperature anticorrosive coating is used for metallurgical high temperature parts?

- The alternating coating of hot and cold can not crack and fall off. The coating is dense, acid resistant and alkali resistant, and can withstand high temperature 1300 DEG C. FDA certification, non-toxic environmental protection.

- Q: What is the cost of the powder metallurgy machine parts?

- The cost of raw materials, auxiliary materials, generally by the artificial and manufacturing cost etc.. Powder metallurgy. The material must be lower than the casting parts. I think it is equivalent to adding a casting process from powder metallurgy to an ordinary casting part.

Send your message to us

Tungsten Carbide Composite Roll for High Speed Wire Mill

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches