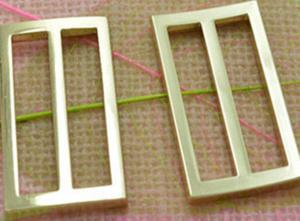

Tri-glide with Cold Rolled Steel for Handbags

- Loading Port:

- Yantian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200000 pc

- Supply Capability:

- 10000 Pieces per Day pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Tri-glide For Handbags

Material:Stainless Steel, Cold Rolled Steel

Finish

Specifications of 100 coatings are available in a range of colors

Quality Control:

1.ISO approved.

2.Inspection at site.

3.Inspection before shipping.

4.testing machine.

Fetures:

A: Eco-friendly( could be Nickel Free, Lead Free)

B: Zinc alloy, with long lasting plating

C: Top quality products in China

D: With more than 15 years rich experiences, make perfect products.

Specifications of Tri-glide For Handbags

Size(inner) :

8mm,10mm,12mm,18mm,20mm,26mm,32mm,38mm,40mm,etc.

Special specification and marks can be made according to customers requirements

Usage/Applications

Widely Used for Bags and Paracords.

Packaging & Delivery

Packaging Detail:A: Each one in a polybag, several bags in a inner carton, several inner cartons in an outer carton. B: or according to your request。

Delivery Detail:Upon the quantity of order or as customer requested.

Service we can provide

1. Good after sales service: Any small problem happening will be solved at the most prompt time;

2. We have many years of experience

3. Specifications list is available upon your request

4. Welcome to send enquiry,we will reply soon.If you want to know more,pls feel free to contact us.

5. Prompt shipment with professional documents

6. Packing as your request, with photo before shipment

7. High quality and competitive price

- Q: What is the top of the crane hook

- The lifting of the crane hook means that the hook rises over the limit and hits the suspension arm pulley block. There are two reasons: 1. from the lifting end, the limit switch failed, 2. from zero to zero, the brake failed, and one of the reasons will cause the impact.

- Q: Hooks need to be made of I steel, and shall not be cold processing, what does it mean?

- First of all, the hook generally bear dynamic load, therefore need to be reinforced with enough flexibility, secondly, hook to omen in the overload after fracture, which is deformed or stretched out, a reinforced good ductility is flexible, it is soft, but obvious omen before fracture, steel cold working can improve the tensile the strength, but the ductility is bad, the elongation decreased under dynamic load capacity is reduced, processing steel needs to be heated, because the steel will produce internal force in the internal of the cold deformation, cause the added strength which is reinforced in cold processing, steel after heating, internal atoms move easily so, do not produce force, the mechanical properties will not change, but don't overdo or quench, naturally cooling slowly, or worse mechanical properties.

- Q: What is the location of the cover plate embedded hook

- All the steel rings, in the bottom of the welding reinforcement, we must set aside the size of the design needs to be exposed.

- Q: How the bridge type crane holds the hook in walking

- Remember to follow, go to the East after a stop in the fight, like the west, where do you open the crane?

- Q: How many centimeters should the crane hook be replaced?

- 5cm need to be replaced.The wear of the dangerous section shall be made by GBl0051.2, which shall not be greater than 5% of the original height, and the hook made by the following standard shall be larger than the original size of 10%.Floating crane is generally divided into fast and slow hook, hook. But the use of large tonnage crane hook is very small. Mainly on the use of small crane. Fast hook is generally a single strand wire rope, lifting speed, high efficiency, slow hook according to the weight of lifting, and many times need on-site return wire rope, so as to be able to lift the goods. Seen the largest is 7-8 of the magnification, mainly on the lifting of heavier goods.

- Q: How to classify lifting hook? What are the advantages and disadvantages?

- The tail of forging hook is usually made of triangular screw thread, and the stress concentration is serious, and it is easy to break at the crack

- Q: Hook crack Hook crack what method of crack detection?what method of crack detection?

- The cracks of crane hook are divided into manufacturing cracks and fatigue cracks. Personal understanding should be fatigue crack.The fatigue crack of the hook usually appears in 2 places:1, the hook of the inner concave plastic deformation or wear place, from the plastic folding initiation;2. The thread position of the straight handle hook;If it is sling, it will be more complicated.Fatigue crack detection generally use magnetic powder or penetration (magnetic powder first), but for the threaded parts may be missing, the need to increase ultrasonic testing;Flaw detection is a relatively strong professional work, the hook is part of the special equipment, the state provides for an annual inspection and testing should be open, non professional staff is not recommended for testing.

- Q: How to wear a steel rope for 20 ton double beam overhead crane?

- From the middle of two respectively through the corresponding side of the movable pulley, then upward through the two fixed pulleys corresponding to one side above the rest, and then put down through the following two sides of the movable pulley corresponding to one side, finally to the steel wire rope is fixed on the fixed on the reel.

- Q: What are the dangerous sections of the crane hook

- by the A-A sling tension section on the one hand, the hook has straightened trend; also by the effect of bending moment on the other hand. Because the moment in this section, the bending stress is maximum, this section is a dangerous section.

- Q: Does the crane hook group include the secondary hook and the main hook

- It is not an auxiliary hook, but the hook is the main hook

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 1992 |

| Annual Output Value | Above US$ 10 Million - US$ 50 Million |

| Main Markets | North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America |

| Company Certifications | ISO 9001:2000 ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen |

| Export Percentage | 60% - 80% |

| No.of Employees in Trade Department | 301 - 500 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | above 2000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Tri-glide with Cold Rolled Steel for Handbags

- Loading Port:

- Yantian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200000 pc

- Supply Capability:

- 10000 Pieces per Day pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords