trapezoidal corrugated Roof Panel Forming Machine 1100mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 300000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Components

1.Manual Decoiler: one set

Un-powered,Manually control steel coil inner bore shrinkage and stop,

Max Feeding width: 1250mm,coil ID range 508mm±30mm

Capacity: Max. 5 Ton

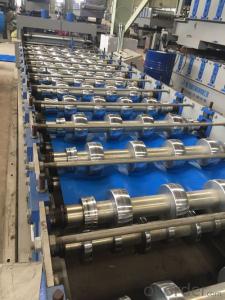

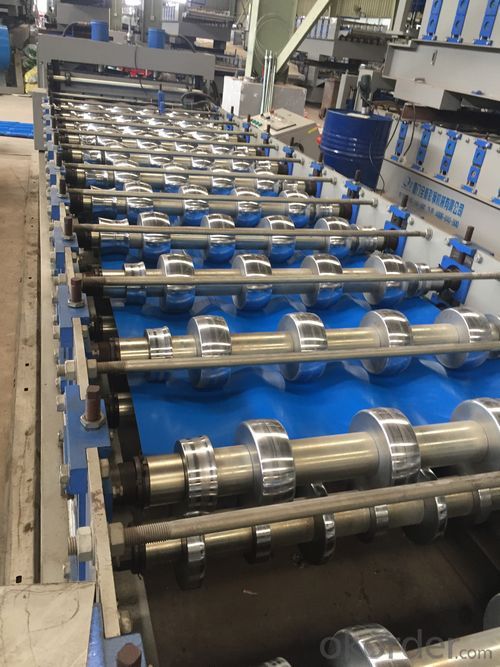

2. Main machine

With feeding material guide, body frame made from H350 type steel by welding;

Rollers manufactured from 45# steel,CNC lathes,Heat Treatment, hard Chrome Coated;

Shafts Diameter=ф75mm,precision machined

Gear/Sprocket driving, about 18-step to form

Main Motor=5.5KW , Frequency speed control

Forming speed approx.13-15m/min

3. Hydraulic Cutting device:

Cutter frame made from high quality 20mm steel plate by welding

Post cut, stop to cutting,Two pieces cutting blades,no blanking

Hydraulic motor: 2.2KW Cutting pressure: 0-12Mpa

Cutting tool material: Cr12, Heat treatment

4. PLC Control System

Control the quantity and cutting length automatically

Combined with: PLC, Inverter, Touch Screen, Encoder, etc

PLC: Delta brand (Taiwan)

Inverter: Delta brand (Taiwan)

Touch Screen: WEINVIEW brand (Taiwan)

Encoder: KOYO brand (Japan)

Cut-to-length tolerance≤±2 mm

5. User's manual in English

- Q: What are the types of logistics equipment?

- According to the equipment in the logistics activities in a considerable position, can be divided into fixed equipment and movable equipment. Fixed equipment such as railway, highway, bridge and tunnel; stations, ports, warehouses and other buildings I equipment such as train, cars, ships, mobile handling equipment.

- Q: How to carry out logistics warehousing operations?

- The central command center can be a project management organization that guides the completion of inventory, new accounts, reports, results of implementation, and progress in each department, while maintaining external customer contacts. The command center should consist of two parts: people and systems.Warehouse management system can implement including import goods management, inventory management, order management, sorting, check, goods and goods, basic information management, replenishment strategy, library mobile combination "wall" system function, but also consider the warehouse management system and transportation management system, interface between customer management, staff management system.The role of man in the command center cannot be replaced by technology. Logistics project managers need to allocate the limited resources on the basis of a large amount of data. Warehousing is not an automated business. There are too many uncertainties in warehousing. It is necessary to take charge of the familiar person inside and outside the warehouse.

- Q: What are the advantages of automated warehousing and its role in logistics systems?

- The utilization rate of logistics resources is low. On the one hand, because the traditional warehouse space caused by the large number of resources in the storage of headroom tend not to use idle waste; on the other hand, because the traditional warehouse management and operation model are used in the original mode of operation, the ability of warehouse equipment did not fully play out, to a certain extent, also caused the waste.

- Q: What are the common logistics equipment?

- According to the special functions of the equipment, it can be divided into transportation equipment, storage and storage equipment, loading and unloading equipment, circulation processing equipment, packaging equipment, information processing equipment, etc..

- Q: What is the warehousing logistics distribution center?

- Storage: first, to solve the seasonal difference between production plan and sale of seasonal time difference. The two is to solve the problem of balance between production and consumption, the need to ensure the normal distribution of the random, meet the needs of users, in the distribution center should not only maintain a certain amount of commodity reserves, but also to store goods kept in maintenance work, to ensure that the number of reserved commodities, ensure good quality. The distribution center serves as a number of production enterprises and commercial outlets (such as chain stores and supermarkets), distribution center according to user requirements timely with good goods sent to all to the hands of users, meet the needs of production and consumption. Distribution center process

- Q: What role does warehousing play in logistics?

- Warehousing conditions are specific tangible or intangible places with modern technology. "Specific", because each enterprise's supply chain is given, the place is of course specific storage; of course refers to tangible places of warehouse, yard or tank, under the background of modern economic, storage can also be carried out in the virtual space, also need a lot of modern technical support, leaving the modern warehouse facility equipment and information technology, there is no modern warehousing.

- Q: The disadvantages of traditional warehousing and the advantages of modern warehousing

- The socialization of warehouse management is not high. Even with the same enterprise, some internal logistics resources can not be shared. As the storage management is backward, the utilization ratio of storage facilities resources is less than 40%, which leads to the low efficiency of logistics

- Q: Storage facilities and equipment is not perfect, what?

- In the future, warehousing centres will be reduced in number, but the number of goods at each center will increase. As a result, the distribution centers are larger on the one hand, and on the other hand, more orders are being processed daily. This means that the speed of the shipment is increased and the receipt, placement, picking and shipment are increased. This trend will put forward higher requirements for material handling systems, and will have a significant impact on forklifts and conveyor belts.

- Q: What shelves are there in the logistics equipment?

- The functions and types of logistics equipment are gradually formed according to the activities of the logistics, and the following categories can be classified according to different standards:According to the unique functions of the equipment, it can be divided into transportation equipment, storage and storage equipment, loading and unloading equipment, circulation processing equipment, packaging equipment, information processing equipment, etc..According to the equipment in the logistics activities in a considerable position, can be divided into fixed equipment and movable equipment. Fixed equipment such as railway, highway, bridge and tunnel; stations, ports, warehouses and other buildings I equipment such as train, cars, ships, mobile handling equipment.According to the service scope of equipment in logistics activities, it can be divided into enterprise (production), logistics equipment and social (supply and marketing) logistics equipment. Enterprise logistics equipment is a part of the fixed assets of enterprises, which belongs to the enterprise of its own equipment, such as transport vehicles, the railway line, handling machinery, packaging machinery, storage and construction: social logistics equipment logistics services for the community, belong to utilities, such as transportation, bridge, port, station etc..

- Q: Common equipment for warehouse logistics equipment

- Three dimensional shelf, conveyor equipment, AGV trolley, reciprocating lift, pallet, etc. 134313 dragon 67497 provide reference!

Send your message to us

trapezoidal corrugated Roof Panel Forming Machine 1100mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 300000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords