Titanium alloy sheet - Strategic emerging industries

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8888 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Titanium Alloy

Titanium is an important structural metal developed in the 1950s. Titanium alloys have high strength, good corrosion resistance, and high heat resistance. From the 1950s to the 1960s, it was mainly to develop high-temperature titanium alloys for aircraft engines and structural titanium alloys for airframes.

From the 1950s to the 1960s, it was mainly to develop high-temperature titanium alloys for aircraft engines and structural titanium alloys for airframes. In the 1970s, a number of corrosion-resistant titanium alloys were developed. Since the 1980s, corrosion-resistant titanium alloys and high-strength titanium alloys have been further developed. development of. The service temperature of heat-resistant titanium alloy has increased from 400℃ in the 1950s to 600~650℃ in the 90s. The emergence of A2 (Ti3Al) and r (TiAl) based alloys makes titanium in the engine's use part is advancing from the cold end (fan and compressor) of the engine to the hot end (turbine) of the engine. Structural titanium alloys are developing toward high strength, high plasticity, high strength, high toughness, high modulus, and high damage tolerance.

In addition, since the 1970s, shape memory alloys such as Ti-Ni, Ti-Ni-Fe, and Ti-Ni-Nb have appeared, and are increasingly used in engineering.

There are hundreds of titanium alloys developed in the world, and the most well-known alloys are 20 to 30, such as Ti-6Al-4V, Ti-5Al-2.5Sn, Ti-2Al-2.5Zr, Ti-32Mo, Ti- Mo-Ni, Ti-Pd, SP-700, Ti-6242, Ti-10-5-3, Ti-1023, BT9, BT20, IMI829, IMI834, etc. [2,4].

According to relevant statistical data, the amount of titanium used in my country's chemical industry reached 25,000 tons in 2012, a decrease from 2011. This is the first time that my country's chemical titanium market has experienced negative growth since 2009. In recent years, the chemical industry has been the largest user of titanium processing materials, and its proportion in the total amount of titanium materials has been maintained at more than 50%. In 2011, it accounted for 55%. However, as the economy is in a downturn, the chemical industry has not only significantly reduced new construction projects, but also faced industrial restructuring, some products have new production capacity under control, and backward production capacity will also be phased out. Affected by this, its shrinkage of the amount of titanium processing materials has become logical. Prior to this, some insiders predicted that the amount of titanium used in the chemical industry will peak between 2013 and 2015. Judging from the current market performance, the weakening of the overall economy in 2012 may make the recession period of titanium for chemical industry advance.

Performance

Titanium is a new type of metal. The performance of titanium is related to the content of impurities such as carbon, nitrogen, hydrogen, and oxygen. The purity of titanium iodide does not exceed 0.1%, but its strength is low and its plasticity is high. The properties of 99.5% industrial pure titanium are: density ρ=4.5g/cubic centimeter, melting point 1725℃, thermal conductivity λ=15.24W/(mK), tensile strength σb=539MPa, elongation δ=25%, cross section Shrinkage ψ=25%, elastic modulus E=1.078×105MPa, hardness HB195.

High strength

The density of titanium alloy is generally about 4.51g/cubic centimeter, which is only 60% of steel. The density of pure titanium is close to that of ordinary steel. Some high-strength titanium alloys exceed the strength of many alloy structural steels. Therefore, the specific strength (strength/density) of titanium alloy is much greater than other metal structural materials. See Table 7-1, which can produce parts with high unit strength, good rigidity and light weight. Titanium alloys are used for aircraft engine components, skeletons, skins, fasteners, and landing gear.

High thermal strength

The use temperature is several hundred degrees higher than that of aluminum alloy. It can still maintain the required strength at medium temperature. It can work for a long time at a temperature of 450 to 500 ℃. These two types of titanium alloys are still very high in the range of 150 ℃ to 500 ℃. Specific strength, while the specific strength of aluminum alloy at 150 ℃ significantly decreased. The working temperature of titanium alloy can reach 500 ℃, aluminum alloy is below 200 ℃.

Good corrosion resistance

Titanium alloys work in humid atmosphere and seawater media, and their corrosion resistance is far superior to stainless steel; they are particularly resistant to pitting, acid corrosion, and stress corrosion; organic substances such as alkali, chloride, chlorine, nitric acid, and sulfuric acid Etc. have excellent corrosion resistance. But titanium has poor corrosion resistance to media with reducing oxygen and chromium salts.

Good low temperature performance

Titanium alloy can still maintain its mechanical properties under low temperature and ultra-low temperature. Titanium alloys with good low temperature performance and extremely low interstitial elements, such as TA7, can maintain a certain plasticity at -253℃. Therefore, titanium alloy is also an important low-temperature structural material.

Great chemical activity

Titanium has a high chemical activity and is compatible with O, N, H in the atmosphere

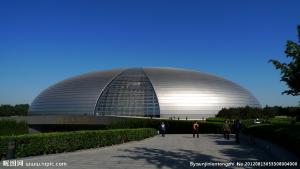

Titanium alloy products

, CO, CO2, steam, ammonia, etc. produce strong chemical reactions. When the carbon content is greater than 0.2%, hard TiC will be formed in the titanium alloy; when the temperature is high, the TiN hard surface layer will be formed when it interacts with N; above 600 ℃, titanium absorbs oxygen to form a hardened layer with high hardness ; Increased hydrogen content will also form a brittle layer. The depth of the hard and brittle surface produced by absorbing gas can reach 0.1~0.15 mm, and the degree of hardening is 20%~30%. Titanium also has a large chemical affinity, and is prone to adhere to friction surfaces.

Low thermal conductivity

The thermal conductivity of titanium λ = 15.24W/ (m.K) is about 1/4 of nickel, 1/5 of iron, 1/14 of aluminum, and the thermal conductivity of various titanium alloys is about 50% lower than that of titanium. The elastic modulus of titanium alloy is about 1/2 of that of steel, so its rigidity is poor and it is easy to deform. It is not suitable to make slender rods and thin-walled parts. The springback of the processed surface during cutting is very large, which is about 2 to 3 of stainless steel Times, causing violent friction, adhesion, adhesive wear on the flank of the tool.

- Q: What does bathroom hardware have?

- Bathroom hardware accessories, generally refers to the installation in the bathroom, the bathroom wall, for placing or hanging clothes cleaning supplies, towel products, general hardware products, including: single hook, towel bar, double towel bar, cup holder, double cup holder, soap dish, soap, towel, towel ring net frame, dresser clip, toilet brush, towel rack, double shelf, and metal faucet, shower and a series of products, you can see only recommend this brand of bathroom products, the only bathroom is mainly ceramic sanitary ware, bathroom furniture, bathroom accessories and other leading hardware, sanitary products, sanitary ware based on integration the three major functional areas, to meet the individual needs of consumers, and provide real-time design of DIY whole bathroom solutions. Unique bathroom calendar three years of careful planning, spending huge sums of money through the power of e-commerce and the experience of cities throughout the country, for the pursuit of affordable and high quality bathroom consumer demand services.

- Q: What does hardware refer to? What's the use?

- [hardware] traditional hardware, also known as "hardware", refers to gold, silver, copper, iron, aluminum, five kinds of metal, processed by artificial, can be made into knives, swords and other art or metal devices. Modern society is more widely used in hardware, today's hardware is often used as a metal or copper, iron and other products collectively. Such as hardware tools, hardware parts, daily hardware, construction hardware and security supplies. Most hardware products are not consumer goods.[hardware use] hardware products, appear in economic life, political life and military activities in every corner. Hardware products of various types, specifications vary, but hardware products in modern life also plays an irreplaceable role in the choice of good hardware fittings, can make many structural parts more safe and convenient to use.

- Q: What hardware fittings are needed for the glass curtain wall project?

- The installation of vertical glass aluminum keel, usually connected with steel connector, connector between the steel and aluminum keel using 2mm rubber pad is isolated by screw connection, M12 stainless steel screw, obtained by calculating the size, with the two level a nut.

- Q: How do you do the hardware business?

- How to communicate with customers in the marketing, there are a lot of communication failures, where and why? In my dictionary, following the so-called communication failure Description: "don't be customer acceptance, or customers do not understand what is said, all invalid. The reason for this communication disorder is that the language situation is too weak, the voice, expression or reading skills are inadequate, the task of making sentences, or lack of interest in communication objects." It is important to build a bridge of trust or goodwill between customers at the first contact with the customer. At the same time, we should first point out the urgency of customer demand for this product, thereby causing customers to buy desire. Almost all salespeople agree that the most difficult part of all sales promotion is communication with customers. In fact, successful communication is difficult because of their different environments and different positions

- Q: Hotel room toilet stainless steel parts, how to maintain?

- Cleaning area, other hardware cleaning and maintenance matters needing attentionThe common hardware in the bath area is bathroom cabinets, metal chains, hinges, slides, towels racks, shelves, frames, etc..

- Q: Does hardware affect the tightness of doors and windows?

- Let me put it briefly.The main window is divided into windows, windows and wood windows and other types of.It is made of glass, section bar, hardware, sealing strip and so on. The sealing of doors and windows is made up of all parts, including the quality of the glass, the quality of the profiles, the quality of the sealant (mainly), the quality of the hardware, the quality of the doors and windows.The tightness is mainly related to the sealing strip they use. For example, the common casement window adopts three yuan ethylene propylene sealant strip, while the sliding window adopts the sealed top.

- Q: What does hardware and electrical appliances include?

- Japanese firms first proposed the concept of Mechatronics in 1970, when they named Mechatronics, which combines mechanical, electrical, and electronic technologies. With the rapid development and wide application of computer technology, mechatronics technology have become a hitherto unknown development, integrated computer and information technology, automatic control technology, sensor technology, servo drive technology and mechanical technology, cross system technology, the forward optical electromechanical integration technology (Opto-mechatronics) development, more and more applications guangzhou.

- Q: What do you have for construction hardware? What do you need to open a hardware store? Is the construction hardware mainly aimed at the construction site? Do we need hardware for real estate?

- Any of various metal and non-metallic fittings mounted on doors and windows of a building. The building door lock, handle, frame, hinge, door closers, handle, bolt, hook, chain, induction door device etc..

- Q: Which part is responsible for leakage of hardware?

- Or forget it, not responsible. Where can I get a lawsuit?.

- Q: Hardware should be how to buy?

- See matching. Bathroom three large sanitary ware in the bathroom occupies the largest position, therefore, can not let sanitary ware to match hardware fittings, but let hardware fittings and sanitary ware match. In the purchase of bathroom hardware accessories, we must consider whether these accessories and purchased sanitary ware match. There are a variety of hardware accessories market, consumers in the choice should pay attention to color, materials and models is consistent with the overall style of the decoration bathroom, if only their own love, it is likely to last pick parts placed in the bathroom will be awkward.

Send your message to us

Titanium alloy sheet - Strategic emerging industries

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8888 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords