Tinplate with good quality and competitive price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

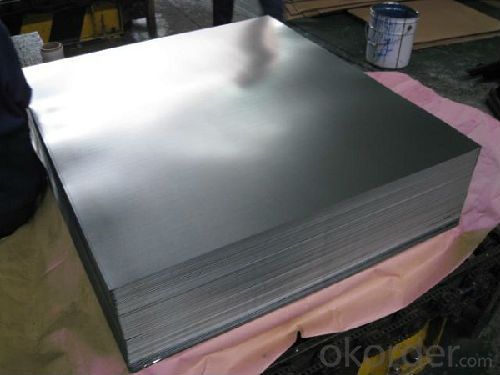

Prime Quality Tinplate Sheets Details

1.Structure of Description

Electrolytic Tinplate Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc. For caps, there are some customers also need TFS, if you have some demand for TFS,also can contact with us.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Minumum Order Quantity: 25 MT Loading Port:China Main Port

Annual Capacity: 400,000MT Payment Terms:TT or LC

Product Specifications:

Prime Quality Tinplate Sheets Usage and Applications

Prime Quality Tinplate Sheets Specifications

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.18

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

Applications

Chemicals and painting cans

Dry food cans, such as fancy cans, biscuit cans, milk power cans, tea cans

Liquid food cans, such as edible oil cans, beverage cans, Tomato paste cans

Sea food cans

Crown corks, easy open ends(EOE)

Electrical machinery parts

Bakeware and household kitchen parts

FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

- Q: A tin rust problem for help

- If the cooling water contains more impurities and negative ions, the sterilization process will lead to an electrochemical reaction. The impurity anion will form a galvanic cell between the Fe at the damage of the coating of the tank, which will lead to rust.

- Q: What are the different methods of joining tinplate components together?

- There are several methods of joining tinplate components together, including soldering, welding, riveting, and adhesive bonding. Each method has its own advantages and is chosen based on factors such as the required strength, aesthetics, and production efficiency of the final assembly.

- Q: Can tinplate be used for renewable energy applications?

- Yes, tinplate can be used for renewable energy applications. It is commonly used in the production of solar panels, wind turbines, and other renewable energy technologies. Tinplate's high strength and durability make it suitable for protecting and housing sensitive electronic components used in these applications. Additionally, tinplate's corrosion resistance ensures the longevity and performance of renewable energy systems, making it an ideal choice for such purposes.

- Q: What are the main countries producing tinplate?

- The main countries producing tinplate are China, Japan, South Korea, and the United States.

- Q: How is tinplate cut and formed into different shapes?

- Tinplate is typically cut and formed into different shapes through a process known as stamping or die-cutting. This involves the use of specialized machines that use sharp dies or punches to cut the tinplate into the desired shape. The tinplate is fed into the machine, and the die or punch is pressed onto it with sufficient force to cut or shape it. This process allows for precise and efficient production of various tinplate shapes, such as cans, containers, or components for various industries.

- Q: What are the different ways to seal tinplate containers?

- There are several ways to seal tinplate containers. Some common methods include using adhesive seals, heat sealing, crimping, or soldering. Adhesive seals involve applying a layer of adhesive to the container's lid, which is then pressed onto the container to create a secure seal. Heat sealing utilizes heat to melt a layer of plastic or wax on the lid, creating a tight bond when cooled. Crimping involves folding and pressing the edges of the container and lid together to create a tight seal. Soldering, on the other hand, uses a heated soldering iron to melt solder onto the seams of the container, creating a strong and permanent seal.

- Q: How does tinplate handle exposure to extreme temperatures?

- Tinplate generally handles exposure to extreme temperatures quite well. It has a high melting point and can withstand high temperatures without deforming or losing its structural integrity. Additionally, tinplate has good thermal conductivity, allowing it to dissipate heat quickly. However, prolonged exposure to extremely high temperatures may cause some oxidation or discoloration on the tin coating. Overall, tinplate is a reliable material for various applications in extreme temperature conditions.

- Q: How does tinplate compare to plastic packaging in terms of sustainability?

- Tinplate generally has better sustainability credentials compared to plastic packaging. Tinplate is made from steel, which is a highly recyclable material, whereas plastic is derived from fossil fuels and has limited recycling capabilities. Tinplate can be recycled indefinitely without losing its qualities, while plastic recycling can be challenging due to different types of plastics and contamination issues. Additionally, tinplate packaging has a longer lifespan and offers better protection for products, reducing the need for excessive packaging. However, it is important to consider the overall life cycle impact, as both materials have environmental implications during production and transportation.

- Q: How does tinplate handle exposure to chemicals and solvents?

- Tinplate is known for its excellent resistance to corrosion caused by chemicals and solvents. It has a protective tin coating that acts as a barrier, preventing direct contact of the metal with the substances. This makes tinplate highly resistant to most chemicals and solvents, ensuring durability and maintaining product integrity.

- Q: Can tinplate be used for military applications?

- Yes, tinplate can be used for military applications. It is a versatile material that offers several benefits such as corrosion resistance, durability, and ease of fabrication. Tinplate can be used for various military applications including ammunition packaging, shelter construction, and equipment protection.

Send your message to us

Tinplate with good quality and competitive price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords