Tinplate in SPCC/MR Grade for Rectangular Cans

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Products: Tinplate

Tinplate and TFS are widely used for making all types of containers such as artistic cans, tea cans, painting cans, chemical package cans and metal printing etc. Its applications are not limited to containers; recently, they have also been used for making electrical machinery parts and many other products.

2. Specification:

Our goods enjoyed high quality both at home and abroad. We can supply tin free steel as follows:

Technical standard | JISG3303 and GB/T 2520-2008 |

Steel Type | MR / SPCC |

Thickness | From 0.15mm to 0.50mm (Tolerance +/- 0.01mm) |

Width | Normally 600-1050mm (Tolerance +3/-0 mm) |

Coating | 2.8/2.8g/m2 , 2.8/5.6g/m2 ,1.1/1.1 g/m2 |

Temper & Annealing | T1-T5, DR7-8, TS230-TH435, T49-T65(+/- 4) |

Surface Treatment | Bright & Fine Stone & Stone & Silver & Matt |

Payment terms | Letter of Credit (L/C), Telegraphic transfer (T/T) |

Price terms | CFR & CIF price term |

Delivery time | Within 60 days after received L/C or T/T down payment |

Packing | High quality shipping packing which contains thin plastic film, rust-proof paper, metal cover, metal angles and strap sand pallet. |

Minimum order Quantity(MOQ) | 25 metric tons (1X 20'' container) |

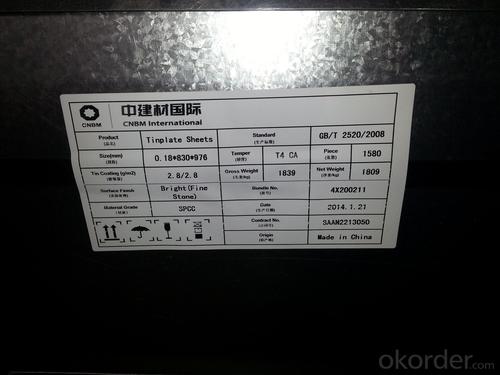

3. Pictures:

4. Features of the factory price/ tin free steel/tinplate/tfs/tmbp/etp/spte:

Beautiful Appearance

Excellent Paintability & Printability

Excellent Formability & Strength

Excellent Corrosion Resistance

Excellent Solderability & Weldability

5. FAQ:

We are one of the main producers in China for tinplate, tin free steel and also TMBP. At present, our productivity is more than 450000 MT/year.

For more information about our products or company, pls contact us freely.

Welcome your enquiries and orders.

- Q: How is tinplate coated for electrical enclosures?

- Tinplate is coated for electrical enclosures through a process called electroplating, where a layer of tin is applied onto a steel sheet. This is achieved by immersing the steel sheet into an electrolyte solution along with a tin anode, and passing an electric current through the solution. The electric current causes the tin ions in the solution to be attracted to the steel sheet, resulting in a thin and uniform tin coating on its surface. This tin coating provides electrical conductivity and corrosion resistance, making the tinplate suitable for use in electrical enclosures.

- Q: What are the different ways to store tinplate containers?

- There are several ways to store tinplate containers, depending on the available space and the specific needs of the items being stored. Some common storage methods include stacking the containers on shelves or pallets, placing them in storage bins or crates, hanging them on hooks or racks, or arranging them in storage cabinets or drawers. The chosen method should ensure easy access, proper organization, and minimal risk of damage to the containers.

- Q: Can tinplate be used for signage and advertising purposes?

- Yes, tinplate can be used for signage and advertising purposes. Tinplate is a versatile material that is durable, weather-resistant, and can be easily shaped and printed on. It offers a great option for creating eye-catching and long-lasting signs and advertisements.

- Q: How does tinplate affect the taste and quality of food?

- Tinplate has a minimal effect on the taste and quality of food. It acts as a protective barrier, preventing the food from coming into direct contact with the metal. This ensures that the taste and quality of the food remain unaffected by any potential reactions with the tinplate.

- Q: Can tinplate packaging be used for promotional items?

- Yes, tinplate packaging can definitely be used for promotional items. Tinplate is a versatile and durable material that can be customized with various designs and branding. It offers a unique and premium look, making it an attractive choice for promotional items such as gift sets, collectibles, or limited edition products. Additionally, tinplate packaging provides excellent protection for the items inside, ensuring their quality and longevity.

- Q: Can tinplate be used for construction applications?

- Yes, tinplate can be used for construction applications. Tinplate, which is a thin steel sheet coated with a layer of tin, offers several advantages such as strength, durability, and corrosion resistance. It is commonly used in construction for various applications including roofing, siding, wall panels, and decorative elements. Additionally, tinplate can be easily formed and shaped, making it suitable for different construction needs.

- Q: What are the different types of tinplate printing techniques?

- There are several types of tinplate printing techniques, including offset lithography, screen printing, and digital printing.

- Q: How does tinplate perform in extreme temperatures?

- Tinplate performs well in extreme temperatures as it has high heat resistance and low thermal expansion properties. It can withstand both extremely high and extremely low temperatures without warping or losing its structural integrity.

- Q: How long does tinplate take to corrode?

- The rate at which tinplate corrodes depends on various factors such as environmental conditions, exposure to moisture, and the presence of corrosive agents. Generally, tinplate is known for its excellent resistance to corrosion, and it can take several years or even decades before any significant corrosion occurs. However, it is important to note that the protective tin coating can wear off over time, making the underlying steel susceptible to corrosion. Regular maintenance and proper storage can help prolong the lifespan of tinplate and prevent corrosion.

- Q: How does tinplate perform in terms of durability and longevity?

- Tinplate is known for its exceptional durability and longevity. Its protective tin coating acts as a barrier against corrosion and prevents the underlying steel from rusting. This makes tinplate highly resistant to environmental factors and ensures its long-lasting performance even in challenging conditions. Additionally, tinplate's strength and rigidity contribute to its durability, making it suitable for various applications where longevity is crucial.

Send your message to us

Tinplate in SPCC/MR Grade for Rectangular Cans

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords