Tinplate for American Market with Bright Surface

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure Description

Electrolytic Tinplate Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Price competitive

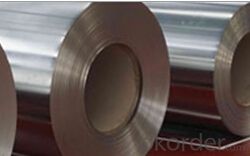

3.Images

4. Specification

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC,MR

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.18

Width :600MM~1000MM

Temper : T1~T5,DR8

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

5.FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

C. What quantity is the minimum order of tinplate?

Usually, the minimum quantity is 25MT. For special case, consult with us.

D. Can it make to be BA or CA for annealing?

Yes, both can do with.

- Q: What are the weight advantages of using tinplate?

- Tinplate offers several weight advantages compared to other packaging materials. Firstly, it is significantly lighter than materials like glass or aluminum, making it easier to handle and transport. This lightweight nature also contributes to lower shipping costs. Additionally, tinplate's lightness allows for more product to be packaged in a smaller space, maximizing efficiency and reducing storage requirements. Overall, the weight advantages of tinplate make it a preferred choice for many industries seeking cost-effective and efficient packaging solutions.

- Q: What are the different coating weights available for tinplate?

- The different coating weights available for tinplate typically range from 1.1 to 11.2 grams per square meter (g/m²).

- Q: Can tinplate be used for packaging baby food and formula?

- Yes, tinplate can be used for packaging baby food and formula. Tinplate is a commonly used material for food packaging due to its durability, corrosion resistance, and ability to protect against light and oxygen. It is also considered safe for food contact and can be easily sterilized, making it suitable for packaging sensitive products like baby food and formula.

- Q: What are the common closure options for tinplate containers?

- The common closure options for tinplate containers include twist-off caps, screw caps, snap-on lids, and pressure-sealed lids.

- Q: Can tinplate packaging be used for pet care products?

- Yes, tinplate packaging can be used for pet care products. Tinplate is a durable and versatile material that provides excellent protection against moisture, light, and oxidation. It can be easily shaped and decorated, making it suitable for packaging various pet care items such as food, treats, supplements, and grooming products. Additionally, tinplate packaging is recyclable, making it an environmentally friendly choice for pet owners.

- Q: How is tinplate used in the manufacturing of kitchenware?

- Tinplate is commonly used in the manufacturing of kitchenware due to its unique properties. It provides a protective coating that prevents corrosion and enhances the durability of the kitchenware items. Tinplate is often used to create food cans, utensils, and other cookware. Its ability to resist corrosion and maintain food quality makes it a popular choice for kitchenware manufacturers.

- Q: Can tinplate be used for aerosol packaging?

- Yes, tinplate can be used for aerosol packaging. Tinplate is a commonly used material for aerosol cans due to its excellent strength, durability, and resistance to corrosion. It provides an effective barrier against moisture and oxygen, ensuring the integrity and longevity of the aerosol product. Additionally, tinplate is easily recyclable, making it an environmentally friendly choice for aerosol packaging.

- Q: How does tinplate perform in terms of odor and taste retention?

- Tinplate performs exceptionally well in terms of odor and taste retention. Due to its impermeable nature, it effectively prevents any external odors or flavors from contaminating the contents of the tinplate container. This makes it an ideal choice for packaging food and beverages, ensuring their freshness and original taste is preserved for an extended period of time.

- Q: How does the printing process affect the durability of tinplate?

- The printing process can have both positive and negative effects on the durability of tinplate. On one hand, the application of a protective coating during the printing process can enhance the tinplate's resistance to corrosion, scratches, and other forms of damage. This can significantly improve its overall durability. On the other hand, if the printing process is not done properly or if low-quality inks or coatings are used, it can weaken the tinplate's protective layer, making it more prone to wear and tear. Therefore, the printing process plays a crucial role in determining the durability of tinplate.

- Q: What are the main differences between tinplate and tinplate laminates in terms of product visibility?

- The main difference between tinplate and tinplate laminates in terms of product visibility is that tinplate laminates have a transparent layer of plastic or other materials on top of the tinplate, allowing for a clear view of the product inside the packaging. In contrast, tinplate alone does not provide this visibility as it is a solid metal material.

Send your message to us

Tinplate for American Market with Bright Surface

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords