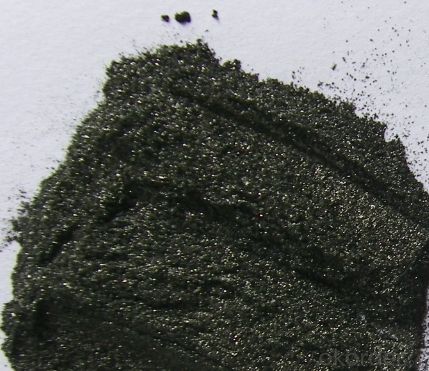

Super Flake Graphite Powder for Locks - Hot Sale for Refractory Materials

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Natural Flake Graphite:

Natural Flake Graphite: Good temperature resistance, self-lubrication, conductivity, thermal shock resistance, corrosion resista

Size of Natural Flake Graphite :

NO. | FixedCarbon | Sulphur | Moisture | Volatile | Graininess |

>= | <=< span=""> | <=< span=""> | <=< span=""> | Granularitydistribution 90% | |

CNBM9805 | 98.50% | 0.05% | 0.50% | 0.50% | 1-5mm |

CNBM9850 | 98.50% | 0.50% | 0.50% | 0.80% | 1-5mm |

CNBM9530 | 95.00% | 0.30% | 0.26% | 1.14% | 1-4mm |

CNBM9330 | 93.00% | 0.30% | 0.30% | 0.9% | 1-5mm |

CNBM9830 | 98.5.00% | 0.30% | 0.50% | 0.5% | 1-5mm |

Performance of Natural Flake Graphite:

flake crystalline integrity, and thin slices of good toughness, excellent physical and chemical properties, good temperature resistance, self-lubricating, conductivity, thermal shock resistance, corrosion resistance performance.

Usage of Natural Flake Graphite :

Widely used in the Tongchang coverage agent, senior refractory materials and coatings in metallurgical industry, military industrial explosive materials stabilizer, lead of light, electrical industrial carbon brushes, the electrode of the battery industry, fertilizer industrycatalyst additives. The flake graphite after deep processing, but also produce milk graphite, graphite sealing materials and composite materials, graphite products, graphite friction reducing additives and other high-tech products become important non-metallic mineral raw materials in various industrial sectors. Also used in the friction material.The particle size can be according to customer requirements.

- Q: How much is one graphite used as electrode?

- Graphite particles 6800 yuan / ton, graphite fine powder 8000 yuan / ton, you buy 30 yuan / kg is the natural graphite powder? Not made of graphite electrodes. The graphite powder used in the electrode is actually synthetic graphite powder.

- Q: Classification of graphite powders

- The classification of graphite powder can be divided into pure graphite, high carbon graphite, carbon graphite and carbon graphite with low carbon content, according to specifications into 50 mesh ~10000 mesh graphite, graphite powder in Qingdao Huatai use can be divided into graphene conductive graphite powder, graphite powder, graphite powder lubrication battery, graphite powder, ultrafine graphite, graphite powder, graphite nano colloidal graphite powder are the type of L.

- Q: How does graphite powder look good or bad?

- High quality graphite powder has high carbon content, superior performance, good quality and wide application range. This is the reason why the quality of graphite powder is higher than other graphite powder.

- Q: Can graphite powder be used in lithium batteries?

- Qingdao Huatai graphite more than 20 years experience in the production of graphite powder to tell you that graphite powder can be used in lithium batteries.

- Q: Whether the lubricating oil toner is coupled with the conductor?

- Not really. It depends on the amount of graphite powder. If the graphite powder forms a continuous through zone, it can be considered a conductorYou can use lubricating oil, preferably not with graphite, which will cause the sliding rheostat to fail

- Q: Use of carburizing agents

- Recarburizer steelmaking using recarburizer (People's Republic of China ferrous metallurgy industry standards, YB/T 192-2001 steel with increased carbon agent) and cast iron using recarburizer, and add some other materials are useful to the carburant, such as brake pads additive for friction materials. The carburizing agent belongs to the raw material of additional steelmaking and ironmaking. High quality carburizing agent is an indispensable additive for the production of high quality steel.

- Q: Distinguish iron powder and graphite powder by chemical method

- 1., add dilute hydrochloric acid or dilute sulfuric acid, the bubble is iron powder2. heating, iron powder is black, graphite is ignited in the air3. is mixed with copper oxide, and heating, plus graphite can be generated to clarify the muddy lime water turbidity CO2, iron powder No.

- Q: Can ultrafine powder iron conduct heat? How many purpose graphite powder can be called superfine stone powder? Pingdu graphite powder which good?

- Ultrafine toner is a thermal conductive function, because ultrafine toner is processed from natural graphite, which inherits the characteristics of natural graphite conduction and heat conduction.

- Q: What companies use graphite powder, graphite particles, graphite ball, silicon carbide alloy ball?

- Iron and steel foundry enterprises, because graphite is a component of carbon, metal inside need to adjust the metal composition, need carbon and silicon to adjust, so will use more.

- Q: Does the graphite powder cause explosion? If so, how to prevent the production of graphite products in the workshop?

- Dust produced in the process of production of some factories and mines, especially the dust produced in the processing of some organic matters, will explode and burn under certain conditions.(2) adequate air and oxidizing agents;(3) there is fire or strong vibration and friction.Such as effective ventilation and biological film, dust suppression technology, integrated dust suppression technology, dust removal measures, smoking and fire operations are prohibited. A pressure relief valve or other device is arranged in the outer shell of the equipment, and an explosion containment system is adopted. For factories with dust explosion hazards, the design must be strictly carried out according to the technical grade of explosion protection, and ventilation and dust removal systems shall be installed separately. Often wet cleaning workshop floor and equipment, to prevent dust flying and gathering. Ensure that the system has a good airtight, if necessary, in airtight containers or pipes in the flammable dust filled with nitrogen, carbon dioxide and other gases, in order to reduce the content of oxygen, dust suppression explosion.

Send your message to us

Super Flake Graphite Powder for Locks - Hot Sale for Refractory Materials

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords