STAINLESS STEEL SELF DRILLING SCREW in STANDARD and NONSTANDARD SIZES

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

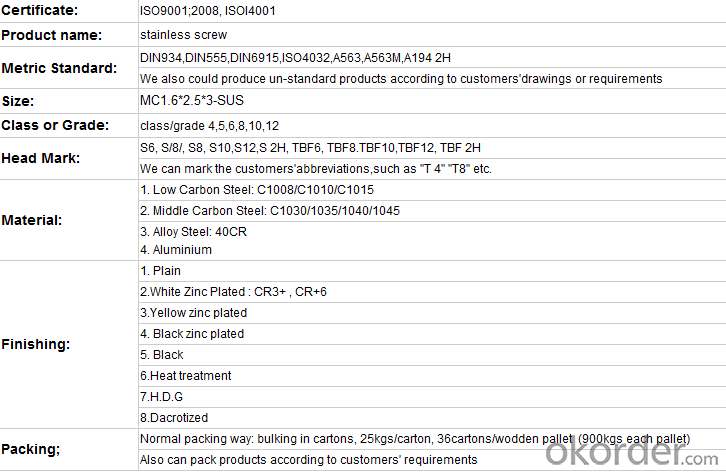

1,description of the stainless steel self drilling screw in standard and nonstandard sizes

2, the products show

3,OUR ADVANTAGE AND SPECIFICATION

1. Our company has been dedicated to producing stainless steel screw, owning complete producing technology and abundant managing experience.

2. The raw material such as mother tube, round bar we use is from Chinese biggest and well-known steel mill

3. We have advanced NDT equipments for the tests such as Eddy Current test, Ultrasonic test, Hydraulic test and so on.

4. We have ISO 9001 and PED certificate, and the Third Party Inspection Certificates such as TUV, BV, Lloyd’s, SGS, etc, also can be provided according to customers’ requirements,

5. Wooden case package which is strong and suitable for sea transportation is our main method to pack the pipes. And the economical packing method such as packed in bundles is also welcomed by some customers.

6. The tolerance control we use is D4/T4 (+/-0.1mm) on both inside and outside Diameter and Wall Thickness, which is much higher than international standard ASTM, DIN.

7. The surface condition is one of our main advantages: in order to meet different requirements for surface condition, we have annealing and pickling surface, bright annealing surface, OD polished surface, OD & ID polished surface etc.

8. In order to keep the inside surface of pipe clean and make it free from deburring, our company develops the unique and special technology --- Sponge Washing with high pressure.

9. We have complete after-sale service to deal with the problems in time.

4,FAQ

Q: WHAT ARE YOUR ADVANTAGES?

A: 1. We have a specialized team in dealing with all the documents required by customers. We aim to zero error to save money and time for client. 2. We have a strict quality control from production to delivery. 3. We take use of advanced system and tool to improve working efficiency and control every step. 4. Professional sales team to serve customers. 5. Samples can be provided as your requirements. 6. Professional packing team which keep every packing safely.

Q: WHAT ARE YOUR MAIN PRODUCT?

A: We are specializing in providing cold rolled 201/410/430 Stainless Steel Coil / Stainless Steel Strip / Stainless Steel Sheet / Stainless Steel Plate, Stainless Steel Circle, Stainless Steel tube / Stainless Steel Pipe Sheets.

Q: CAN I GET FREE SAMPLE?

A: YES. We can provide free sample. However, you should be responsible for the transportation freight. Please tell us your express account or please send us the transportation freight of samples firstly, then we can arrange sample delivery.

Q: HOW MUCH THE TRANSPORTATION FREIGHT WILL BE FOR THE SAMPLES?

A: The freight depends on the weight and packing size and your area.

- Q: What is the meaning of the screw and the 4 and 8?

- Screw should be written on the 4.8 bar, 4.8 on behalf of the strength level

- Q: The mirror under the mirror put the toilet glass is broken, the original screw rust deformation, and pulled out. How to rust the screw

- The easiest way to change the place to hang the original place to hang a mural

- Q: I'm talking about another thing

- crews for the daily life of indispensable industrial necessities: such as cameras, glasses, watches, electronics and other small screws used; television, electrical products, musical instruments, furniture and other general screws; as works, construction, bridges are large Screws, nuts; transport equipment, aircraft, trams, cars, etc. are the size of the screw and use. Screws have an important task in industry, and as long as there is industry on earth, the function of screws is always important. Screw is thousands of years of people in the production of common inventions, according to the application field, it is the first major inventions of mankind.

- Q: Is the tail screw? If it is mainly used in what place? If not what are they different?

- Yes, can be directly set in the material, the basic material on the drilling, mainly used in the steel structure of the color steel tile can also be used for simple construction of thin plate fixed.

- Q: Why should the screw twist clockwise?

- Because the screw on the original flute is the clockwise direction of it

- Q: Why are the screws of the screw?

- Fine thread thread pitch is small, the angle is small, self-locking is better, high strength, because the teeth are not wearable, easy to slip. Fine thread is often used in fine parts, thin-walled pipe fittings or by the impact, vibration and variable load connection, can also be used as fine-tuning mechanism for adjusting the thread.

- Q: How much is a screw?

- To see what screwdriver, if it is a small screw, and then you buy more words, a single cost may be a few cents, if it is a single purchase may be more expensive.

- Q: Who knows who invented the screw?

- The spirits were invented more than 2,000 years ago, but less than 500 years for fixing things. The first person who describes the spiral is the Greek scientist Archimedes (about 287 BC - 212 BC) The Archimedes spiral is a huge spiral in a wooden cylinder used to The water is raised from one level to another, and the fields are irrigated. Its true inventor may not be Archimedes himself. Maybe he just described something that already existed. Perhaps it was the ancient Egyptian craftsmen who had designed it to use the irrigation on both sides of the river. Archimedes spiral in the ancient society are used to raise water, no one considered to change it into a fixed piece. Archimedes spirals are widely used for water lifting. For example, the Romans used it to drain the mine. In the Middle Ages, carpenters used wooden nails or metal nails to connect furniture and wooden structures. In the 16th century, nail workers began to produce spiral nails, these nails can be more firmly connected things. It was a small step from this nail to the screw. At the end of the eighteenth century, screws were quite popular as fixed parts, because at that time a cheap production method had been found. Screwdriver (chisel) appeared in London around 1780 years. The carpenter found that screwing the screw with a screwdriver was better than a hammer and could fix something better, especially when a fine screw was encountered.

- Q: What is the invention of the screw?

- Screws Today, many things are screwed together. Look around the house, the eyes see all kinds of things - from furniture to food processors, are connected with screws. The spirits were invented more than 2,000 years ago, but less than 500 years for fixing things. The first man who describes the spiral is the Greek scientist Archimedes (about 287 BC - 212 BC). The Archimedean spiral is a huge spiral in a wooden cylinder that is used to raise water from one level to another and irrigate the fields. Its true inventor may not be Archimedes himself. Maybe he just described something that already existed. Perhaps it was the ancient Egyptian craftsmen who had designed it to use the irrigation on both sides of the river. Archimedes spiral in the ancient society are used to raise water, no one considered to change it into a fixed piece. Right: Archimedes spiral is widely used for water. For example, the Romans used it to drain the mine. In the Middle Ages, carpenters used wooden nails or metal nails to connect furniture and wooden structures. In the 16th century, nail workers began to produce spiral nails, these nails can be more firmly connected things. It was a small step from this nail to the screw. At the end of the eighteenth century, screws were quite popular as fixed parts, because at that time a cheap production method had been found. Screwdriver (chisel) appeared in London around 1780 years.

- Q: How is the screw produced

- There are three types of technology: cold heading, red, turning; rolling teeth generally have four kinds of technology: rubbing teeth, rolling wire, teeth, car teeth; but our screw industry is the most common Is the beginning of the cold heading, the machine rubbing teeth, so that large output, low cost

Send your message to us

STAINLESS STEEL SELF DRILLING SCREW in STANDARD and NONSTANDARD SIZES

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords