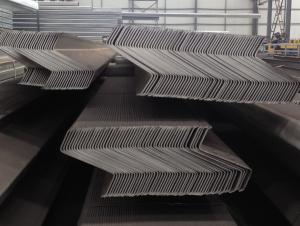

Finland Solar Pv Mounting Systems - Stainless Steel Hook for Flat, Pitched, Butler, and Standing Seam Roofs

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless Steel Hook, Flat Roof Pitched Roof Butler Roof Hook, Standing Seam Roof Hook

Specifications

Hot Selling Stainless Steel Hook:1)ISO 9001,AS/NZS 1170&TUV&MCS certified

2)Fit all kinds of panels

3)Easy installation

Technical Information:

Material | Aluminum AL6005-T5 & SUS 304 |

Standard | AS/NZS 1170, TUV |

Install Site | Flat Roof |

Install Angle | 0-60 degree |

Max Building Height | 20 m |

Wind load | Up to 130mph(60m/s) |

Snow Load | Up to 30psf(1.4kN/m2) |

Anticorrosive | Anodized or hot galvanized |

Color | Natural or Customized |

Warranty | 10 years |

Duration | More than 20 years |

- Q: Can a solar mounting system be used in areas with limited access to quality control measures?

- Yes, a solar mounting system can be used in areas with limited access to quality control measures. However, it is important to ensure that the system is designed and installed by experienced professionals who follow industry standards and guidelines. Adequate training and supervision can help overcome the challenges of limited quality control measures and ensure the system's performance and longevity.

- Q: Are there any specific requirements for installing solar mounting systems in areas with high air pollution?

- Yes, there are specific requirements for installing solar mounting systems in areas with high air pollution. The primary concern is to ensure that the solar panels and mounting structures are regularly cleaned and maintained to prevent the accumulation of dust and pollutants that can reduce their efficiency. Additionally, it is important to choose materials and coatings that are resistant to corrosion caused by air pollution. Regular monitoring and cleaning schedules should be implemented to ensure optimal performance in such areas.

- Q: Can a solar mounting system be used in areas with solar incentives for research institutions?

- Yes, a solar mounting system can be used in areas with solar incentives for research institutions. Solar mounting systems are designed to securely install and support solar panels, allowing them to harness sunlight and convert it into electricity. When installed in areas with solar incentives, such as government grants or tax credits, research institutions can take advantage of these benefits to invest in and promote renewable energy research. By utilizing solar mounting systems, research institutions can contribute to reducing their carbon footprint and achieving their sustainability goals while also benefiting from the financial incentives provided by the local government or relevant programs.

- Q: Can a solar mounting system be used in areas with unstable power grids?

- Yes, a solar mounting system can be used in areas with unstable power grids. Solar mounting systems are designed to function independently from the power grid, relying solely on the energy generated from sunlight. This allows them to provide a stable and reliable source of electricity even in areas with inconsistent or unreliable power supply. Additionally, solar systems can also incorporate battery storage solutions to store excess energy generated during peak sunlight hours, further enhancing their ability to operate in areas with unstable power grids.

- Q: What is the metal material for the RESOLUTE bracket?

- If the core of the stent is a lipophilic molecule, it is compatible and firmly wrapped in drugs, in 6 months and longer time a small amount of uniform release of drugs to ensure sustained and stable drug stent effect.

- Q: Are there specific requirements for the roof to install a solar mounting system?

- Yes, there are specific requirements for installing a solar mounting system on a roof. The most important requirement is that the roof should be structurally sound and capable of supporting the weight of the solar panels. Additionally, the roof should have enough unshaded space to accommodate the panels and receive adequate sunlight. The orientation and angle of the roof may also affect the efficiency of the solar system. It is recommended to consult with a professional solar installer to assess the specific requirements for your roof.

- Q: Can a solar mounting system be used on RVs?

- Yes, a solar mounting system can be used on RVs. It allows RV owners to install solar panels on the roof or any available space to generate electricity and power various appliances while on the move. This helps to reduce reliance on traditional power sources and provides an environmentally friendly solution for energy needs while traveling.

- Q: Can a solar mounting system be used on agricultural buildings?

- Yes, a solar mounting system can be used on agricultural buildings. These systems can be installed on the roofs or open areas of agricultural buildings, allowing farmers to harness solar energy for their operations. This helps in reducing electricity costs and promoting sustainable practices in agriculture.

- Q: Can a solar mounting system be used with bifacial solar panels?

- Yes, a solar mounting system can be used with bifacial solar panels. In fact, bifacial panels are designed to capture sunlight from both sides, making them suitable for use with various mounting systems, including those designed for traditional monofacial solar panels.

- Q: Can a solar mounting system be installed on a rooftop with a vinyl roof?

- Yes, a solar mounting system can be installed on a rooftop with a vinyl roof. The mounting system is designed to be adaptable and can be installed on various roofing materials, including vinyl. It is important to ensure that the vinyl roof is in good condition and can support the weight of the solar panels and mounting system. Additionally, it is recommended to consult a professional installer to ensure proper installation and to prevent any damage to the vinyl roof.

Send your message to us

Finland Solar Pv Mounting Systems - Stainless Steel Hook for Flat, Pitched, Butler, and Standing Seam Roofs

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords