Solid Wood Moulding

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 meters m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

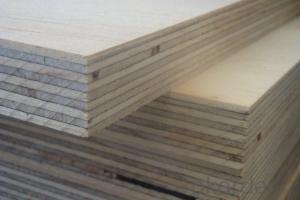

Specifications of Solid Wood Moulding

1.Name:wood moulding

2.ISO/FSC certificate

3.Customized design

4.No warp in different temperature

5.Wood:alder, okume ,oak,sapele,cherry..

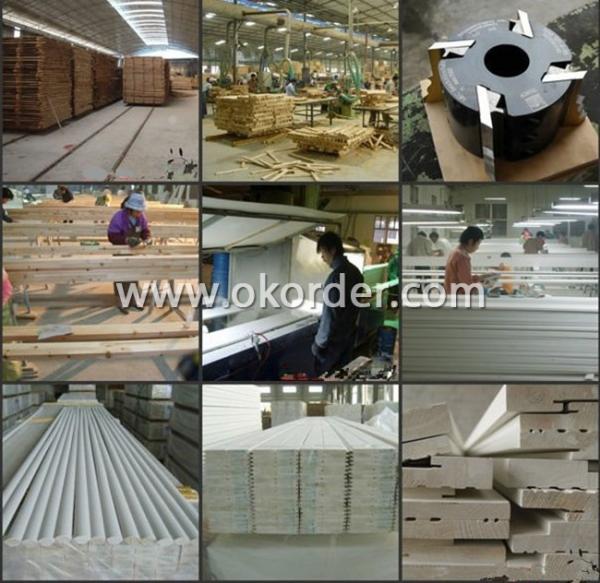

Manufacturing process:

1. Moulding preparation

The wood blanks are maufactured in mouling profiles.

2. Surface sand following moulding preparation, Machined(produced) with high speed planing equipment to yield a premium finish timber moulding ready for priming with a gesso coating.

3. Priming-stage:Mouldings are spray-coated with the 1st application of thin gesso coating.

4. Intermediate sanding stage:Surface sand following priming stage 1

5. Mouldings are spray-coated with the 2st(and final) application of water base primer.

6. Final product check with light sand and buff to the surface,that is readily painted with quality topcoats

Quality standards

1. Moisture content must be accurately tested with an electronic moisture meter.

2. All dimensions should be within the dimensional tolerances as specified on the order

3. Coating application would be applied equally on all edges and has a strong adhesion

to the wood substrate throug testing .No visible defects like patching,open finger joints,

bleed through,etc,after being coated/primed.

4. Mouldings would stay straight and not have excessive bow or spring.

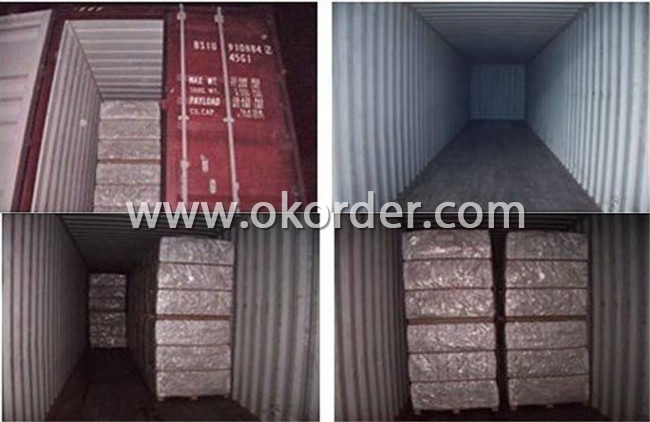

Packing&Loading

1. All mouldings to be packed in mini-bundles secured with tape, within the main pack structure.

2. Packs will be then strapped securely with poly strapping (to be confirmed by customer) to secure for shipment.

3. All bottom packs are secured to a plywood pallet that allows containerisation and unloading.

Hot Products:

Production Progress:

Packing:

- Q: The Similarities and Differences of Ecological Board and Solid Wood Board

- Product Features Corrosion-resistant, scratch-resistant, anti-ultraviolet light Features , Is widely used

- Q: Wood board with solid wood board what are the advantages and disadvantages

- Plywood large and smooth format, the size of accurate and uniform thickness, suitable for furniture, a variety of doors, roof, floor panels and other large area plate parts

- Q: The difference between high density board and solid wood board

- Solid wood panels are generally classified according to the physical name of the plate, there is no uniform standard specifications.

- Q: The use of solid wood panels

- can be considered for the protection of forest resources, accelerate the construction of ecological civilization to make some due contribution

- Q: decorative panels, manufacturing and solid wood the same effect

- Common veneer color from shallow to deep, cherry, maple, White beech, red beech, ash, white oak, red oak, teak

- Q: What is a solid wood board in a paintless board?

- n addition, due to the special production process, it variety, the world's popular tree species everything.

- Q: What is the difference between solid wood board and big core board?

- At present, in addition to the floor and the door will use solid wood, the general use of our plates are manually processed wood-based panels.

- Q: Distinguish between ecological board and solid wood board

- X0d With the limited timber resources, man-made sheet to become a house Decoration of the wise choice, the ecological board to make a good job to make up for the vacancy, ecological board, as the name suggests:

- Q: Is the fire board used siliceous material or calcium material as the main raw material?

- Fire board is made of siliceous material or calcium material as the main raw material, with a certain proportion of fiber material, light aggregate

- Q: What are solid wood characteristics

- Second, the wood varieties 1, solid wood board. As the name suggests, solid wood is made of complete wood made of wood.

Send your message to us

Solid Wood Moulding

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 meters m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords