Solar Pump Inverter for New Solar Water Pump with Helical Screw

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 300 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

how is the rotor made:

how is the motor made:

the pump :

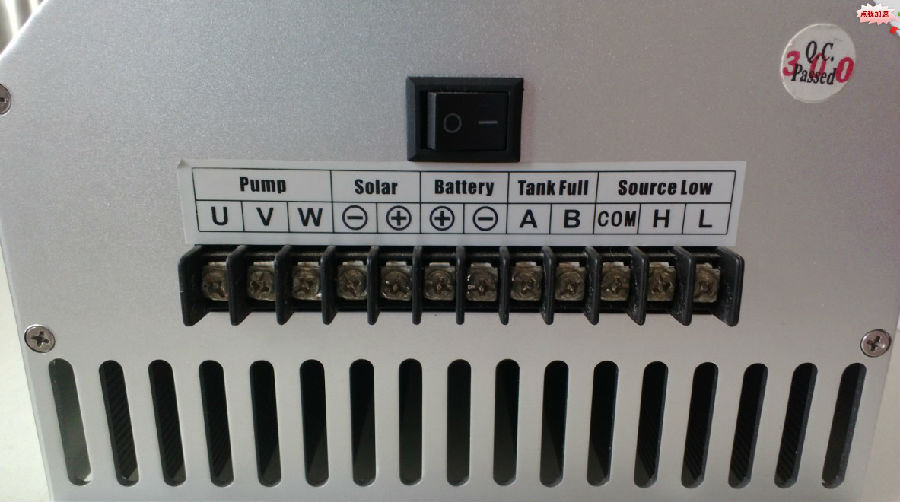

controller terminal connection:

The permanent magnet:

the helical screw:

controller box:

the senors:

the test:

the application:

the package:

- Q: How long does it take to install a solar pump?

- The installation time for a solar pump can vary depending on various factors such as the size and complexity of the system, site conditions, and the expertise of the installation team. However, on average, a typical solar pump installation can be completed within a few days to a couple of weeks. It is recommended to consult with a professional installer who can assess your specific requirements and provide a more accurate estimate.

- Q: Can a solar pump be used in residential applications?

- Yes, a solar pump can definitely be used in residential applications. Solar pumps are a great alternative to traditional electric pumps for various residential purposes such as providing water for household use, irrigation, or even pool circulation. They harness the power of the sun to operate, eliminating the need for grid electricity and reducing energy costs. Additionally, solar pumps are environmentally friendly, producing zero greenhouse gas emissions and reducing dependence on fossil fuels. They are also easy to install, require minimal maintenance, and can be a reliable source of water in remote or off-grid areas. Overall, a solar pump is a viable and efficient option for residential applications.

- Q: How does a solar pump handle water source pollution from agricultural activities?

- A solar pump itself does not directly handle water source pollution from agricultural activities. However, it can indirectly help mitigate pollution by providing a reliable and sustainable source of water for irrigation. By using solar energy to power the pump, it reduces dependence on fossil fuels and minimizes carbon emissions. This, in turn, contributes to reducing air and water pollution associated with conventional pump systems. Moreover, solar-powered pumps are often used in conjunction with drip irrigation systems, which can help optimize water usage and reduce the risk of contamination from excessive fertilizer or pesticide application. Overall, while a solar pump does not directly address water source pollution, it plays a role in promoting eco-friendly and efficient agricultural practices that can contribute to reducing pollution.

- Q: Can solar pumps be used for livestock watering?

- Yes, solar pumps can be used for livestock watering. Solar-powered water pumping systems can provide a sustainable and cost-effective solution for supplying water to livestock in remote areas where grid electricity is limited or unavailable. These pumps use solar energy to power the pump and move water from a source, such as a well or pond, to livestock watering troughs, ensuring a reliable and continuous water supply for the animals.

- Q: Can a solar pump be used for agricultural spraying or sprinkler systems?

- Yes, a solar pump can be used for agricultural spraying or sprinkler systems. Solar pumps use energy from the sun to power water pumps, making them an environmentally friendly and cost-effective option for various agricultural applications, including irrigation and sprinkler systems. These pumps can provide a reliable and sustainable water supply for efficient crop watering and maintenance.

- Q: What is the expected maintenance schedule for a solar pump?

- The maintenance schedule for a solar pump can vary depending on factors such as the pump's type and model, the quality of its components, the environmental conditions it operates in, and how much it is used. However, in general, a solar pump requires less maintenance than traditional pumps because of its simple design and reliance on renewable energy. To keep a solar pump in good condition, it is important to regularly perform the following tasks: 1. Keep the solar panels clean: To ensure the pump absorbs sunlight efficiently, it is necessary to clean the panels regularly, removing dust, dirt, and debris. A soft cloth or sponge and mild detergent should be used for cleaning, avoiding any abrasive materials that could scratch the surface. 2. Inspect the wiring and connections: It is important to periodically check the electrical wiring and connections to ensure they are secure and free from wear or damage. Loose or faulty connections can lead to reduced performance or system failure. 3. Monitor water levels: Depending on the type of solar pump and its application, it may be necessary to regularly check the water levels. This is especially important for pumps used in irrigation systems or remote water supply, as low water levels can cause the pump to overheat or run dry, potentially damaging the motor or pump components. 4. Lubricate moving parts: Some solar pumps may require occasional lubrication of moving parts, such as bearings or seals, to prevent friction and ensure smooth operation. It is essential to use the recommended lubricant and follow the manufacturer's guidelines for proper application. 5. Maintain the batteries: For solar pumps with battery backup systems, it is crucial to monitor and maintain the batteries. This includes checking the charge level, cleaning the battery terminals, and replacing batteries if necessary. Proper battery maintenance is essential for consistent pump performance, especially during periods of low sunlight or at night. 6. Seek professional servicing: While routine maintenance can be done by the user, it is advisable to have a professional service the solar pump periodically. This allows for a thorough inspection, testing of system components, and identification of any potential issues that may require attention. It is important to note that the manufacturer may provide specific maintenance requirements in the user manual or documentation. Following the recommended maintenance schedule and guidelines provided by the manufacturer will ensure optimal performance and longevity of the solar pump.

- Q: How long does it take to recoup the cost of a solar pump through energy savings?

- The time it takes to recoup the cost of a solar pump through energy savings can vary depending on factors such as the initial cost of the pump, the energy efficiency of the pump, the amount of energy savings achieved, and the local energy rates. However, on average, it can take anywhere from 5 to 10 years to recoup the cost of a solar pump through energy savings.

- Q: Can solar pumps be used for water supply in remote research stations or observatories?

- Yes, solar pumps can be used for water supply in remote research stations or observatories. Solar pumps are an ideal solution for remote locations as they are not dependent on grid electricity and can operate using solar energy. They provide a sustainable and reliable source of water supply, making them suitable for remote areas where access to electricity may be limited. Additionally, solar pumps require minimal maintenance and have a long lifespan, making them a cost-effective and efficient option for water supply in remote research stations or observatories.

- Q: Can a solar pump be used for water circulation in cooling systems?

- Yes, a solar pump can be used for water circulation in cooling systems. Solar pumps are designed to run on solar power, which means they can operate without being connected to the grid. This makes them a sustainable and cost-effective option for water circulation in cooling systems, especially in areas with abundant sunlight. Solar pumps can be used to circulate water through heat exchangers, radiators, or other cooling components, helping to remove heat and maintain optimal temperatures in the system. They are commonly used in solar water heating systems and can also be utilized in air conditioning systems or industrial cooling processes. Overall, solar pumps offer a green and efficient solution for water circulation in cooling systems, reducing energy consumption and environmental impact.

- Q: Can a solar pump be used for water supply in commercial buildings?

- Certainly! Solar pumps are an excellent choice for water supply in commercial buildings. They offer efficiency and cost-effectiveness, making them a reliable solution. By utilizing solar energy, they not only operate in an environmentally friendly manner but also help reduce operating expenses. These pumps serve multiple purposes, including irrigation, plumbing systems, and even fire suppression systems in larger commercial buildings. The adaptability and dependability of solar pumps make them a suitable option for meeting the water supply requirements of commercial buildings. Furthermore, they require minimal maintenance and have a long lifespan, making them a sustainable choice for water supply in commercial settings.

Send your message to us

Solar Pump Inverter for New Solar Water Pump with Helical Screw

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 300 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords