Safety Rotary Slip of Type MP with API 7K Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Safety Rotary Slip of Type MP Description

Safety Rotary Slip are tools for handling flush joint pipe and drill collar. There are three types of safety Rotary Slip:Type WA-T, Type WA-C and Type MP.

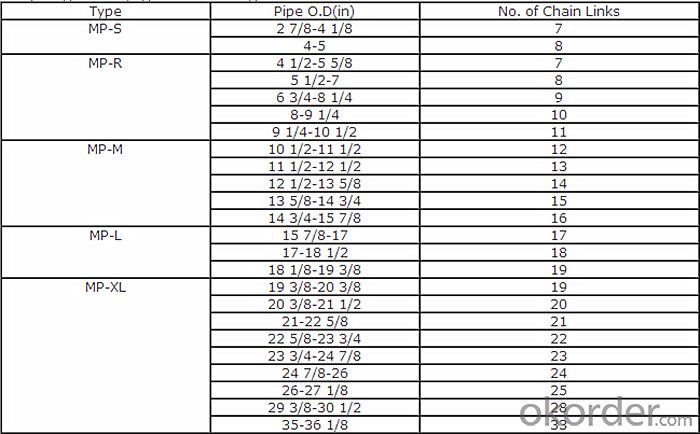

MP Safety Clamps can accommodate pipe from 2 7/8 to 36 1/8 O.D.

2. Main Features of Safety Rotary Slip of Type MP

1) API standard;

2) Very Good Quality;

3) After-sale Service.

3. Safety Rotary Slip of Type MP Images

4. Safety Rotary Slip of Type MP Specification

5. FAQ of Safety Rotary Slip of Type MP

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class supplier of Mannual Tongs. Our products have been sold to various domestic oilfields and exported to Europe, America, Middle East, Central Asia, North Africa and South-East Asia and other overseas regions.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

We will arrange the delivery as soon as possible after receiving the contract.

- Q: What spare parts does mine machinery equipment have?

- My company with good products, reliable reputation, reasonable prices and warm service, is willing to work with you sincere cooperation, hand in hand, and pioneering and innovative, and seek common development!

- Q: What are the common faults of tower cranes? Removal method

- 1., the tail thread and withdrawal groove, hook surface cracks2. hook dangerous section wear3., hook and bending parts of permanent deformation

- Q: China's most powerful mine wear parts

- In addition, the wear-resistant parts of the processing technology and technology is very important, it is best to find professional wear-resistant parts processing enterprises to do, such as steel and so on.

- Q: What are the accessories for mining machinery?

- Bearings, screens for vibrating screens, belts for belts, etc.!! A lot of ah, these are worn parts, what's the problem, ask me again, see the signature on the phone

- Q: What are the accessories for mining machinery?! Mainly refers to?

- Screws, screws, caps, lubricants, gears, belts are things used in mining machinery. Do you understand?

- Q: How to do the maintenance of mining machinery parts?

- Reduce the influence of mechanical impuritiesMechanical impurities are generally referred to as dust, soil and other non-metallic materials and mining machinery in the process of its own production of a number of metal debris, wear products, etc.. Once these impurities into the internal machinery to match surface mechanical, its harm is great, not only make out the relative motion block, accelerated wear parts, and will scratch with the surface, destruction of the lubricant film, make parts temperature and oil deterioration.For the mining machinery work in harsh environment and complex condition places, one is to use high quality, supporting components and lubricating oil and grease, the source block harmful impurities; two to do a good job of mechanical protection work site, ensure the corresponding mechanism to work, to prevent the impurities from entering the internal machinery. For failure of machinery, as far as possible to the formal repair site repair. Site repair, but also to do a good job of protection measures to prevent on-site repair parts replaced by dust and other impurities before entering the machinery.

- Q: I would like to ask the general mine machinery industry, the purchase of accessories must not go to the original factory to buy?

- No, now a lot of mining machinery manufacturers are doing, you can choose any accessories manufacturers, if you buy the original equipment manufacturers are not given, then why do you want to buy it for him, you find other mining equipment manufacturers to buy the same.

Send your message to us

Safety Rotary Slip of Type MP with API 7K Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches