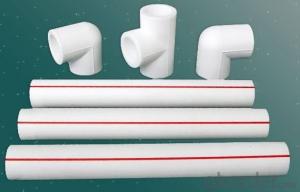

Rv Plastic Pipe Fittings PPR Coupling for Hot and Cold Water Conveyance from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

The comprehensive technical performance and economic indicator of PP-R are much better than galvanized pipe, UPVC pipe, polyethylene-aluminum compound pipe, PE-X (cross-linked polyethylene) and polybutylene pipe etc. For this reason PP-R is the leading products and widely used for feed-water piping in developed countries in Europe and America.

Nowadays PPR pipes win more attention and have been used all over the whole world more widely with its excellent sanitization performance, high heat resistance, compression resistance, corrosion resistance, pliability and seismic performance which make PP-R the real environmental friendly pipe.

Advantages

1. Light weight, easy and quick assembly

2. Most suitable for carrying drinking water

3. Excellent corrosion and chemical resistance

4. Bacteriologically neutral

5. Low thermal conductivity

6. Safe and watertight joints

7. Reduce heat loss

8. Resistance to scaling

9. Resistance to frost

10. Usable in seismic areas

11. Resistance to abrasion

12. Resistance to stray current

13. Eco-friendly

14. Long operational durability

Product Description

Product Show

Why choose us?

(1) Professional factory: We are manufacturer, specializing in manufacturing multilayer PP-R, PE pipe and PP-R, PE pipe fittings for more than13 years, our price is competitive with high quality. And we can delivery product in quick way.

(2) Sample: We can send samples out in 3 days, but the express charge usually paid by your side, but the fee will be rebound when we have formal order.

(3) Rapid response to your needs: We will be answer within 24 hours. Welcome to contact with us if you have any problems. We are looking to cooperating with you.

(4) We hope we can establish long-term and mutual benefit business relation with you. If you have any problem, please kindly feel free to contact me. I will try the best to help you!

- Q: Can plastic pipe fittings be used in fish farming systems?

- Yes, plastic pipe fittings can be used in fish farming systems. Plastic fittings are commonly used in aquaculture due to their durability, chemical resistance, and affordability. They are suitable for various applications, such as water supply, drainage, aeration, and filtration systems in fish farming operations.

- Q: What is the maximum temperature that plastic pipe fittings can handle?

- The maximum temperature that plastic pipe fittings can handle depends on the specific type of plastic used. However, most plastic pipe fittings can typically handle temperatures up to around 140°F (60°C) before they start to degrade or deform. It is important to consult the manufacturer's guidelines or specifications for the specific type of plastic pipe fittings being used to ensure safe and proper usage.

- Q: Are plastic pipe fittings resistant to sulfuric acid?

- No, plastic pipe fittings are not typically resistant to sulfuric acid.

- Q: Can plastic pipe fittings be used in radiant floor heating systems?

- Yes, plastic pipe fittings can be used in radiant floor heating systems. Plastic fittings, such as those made from PEX (cross-linked polyethylene), are commonly used in radiant floor heating installations due to their flexibility, durability, and resistance to corrosion. These fittings are easy to install, provide leak-free connections, and are compatible with various types of plastic pipes used in radiant floor heating systems.

- Q: Can plastic pipe fittings be used for swimming pool plumbing?

- Yes, plastic pipe fittings can be used for swimming pool plumbing. They are commonly used due to their durability, resistance to chemicals and corrosion, and ease of installation.

- Q: Are plastic pipe fittings suitable for chemical dosing applications?

- Plastic pipe fittings are generally suitable for chemical dosing applications. They offer advantages such as corrosion resistance, lightweight construction, and ease of installation. However, the specific chemical being dosed should be considered when selecting the type of plastic fitting to ensure compatibility and prevent any potential chemical reactions or degradation.

- Q: How do you connect plastic pipe fittings to ABS pipes?

- To connect plastic pipe fittings to ABS pipes, you can use a solvent cement specifically designed for ABS materials. Clean the ends of both the fitting and the pipe, apply the cement evenly to both surfaces, and then firmly push them together. Allow sufficient time for the cement to dry before using the pipe.

- Q: How do you connect plastic pipe fittings to PVC pipes?

- To connect plastic pipe fittings to PVC pipes, you can use PVC cement or adhesive specifically designed for joining PVC materials. Simply apply the cement to the inside of the fitting and the outside of the PVC pipe, then push them together firmly. Allow sufficient time for the cement to dry and create a strong, permanent bond between the plastic pipe fittings and PVC pipes.

- Q: Are plastic pipe fittings resistant to corrosion?

- Yes, plastic pipe fittings are resistant to corrosion.

- Q: Are plastic pipe fittings suitable for high-pressure systems?

- No, plastic pipe fittings are generally not suitable for high-pressure systems as they may not have the required strength and durability to withstand the pressure levels. Metal fittings are generally recommended for high-pressure systems.

Send your message to us

Rv Plastic Pipe Fittings PPR Coupling for Hot and Cold Water Conveyance from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords