Rock Wool Refractory Ceramic Fiber Board for Steam Pipe Insulation Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

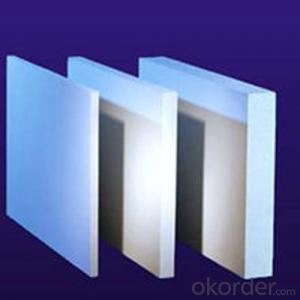

Refractory Ceramic Fiber Board for Steam Pipe Insulation

Product Description

![]()

Description of ceramic fiber board for steam pipe insulation:

Zibo tongfa ceramic fiber board offers a family of high temperature ceramic fiber board,which are produced through wet forming process of ceramic fiber and binders.ceramic fiber board is featured with high temperature stability,low thermal conductivity,even density,and excellent resistance against thermal shock and chemical attack.Ceramic fiber board also resists oxidation and reduction. If they are wet by water,steam,or oil,physical and thermal properties are fully restored upon drying. Ceramic fiber board is used for a variety of high temperature applications, including refractory linings,backup insulation, baffles and muffles, heat shields, combustion chambers, flue insulation, and fire protection.

These ceramic fiber board are available in a variety of temperature ratings, densities,thickness, widths and lengths, and custom vacuum formed shapes. These materials can use in great variety of applications in high temperature insulation industries

1. Ceramic Fiber Board was processed by the advanced production line, which was adopted the full automatic control and the continuous- processing method.

2. Ceramic Fiber Board have many typical characteristics, such as exact measurement,excellent toughness,excellent heat preservation and can be cut discretionally

3. The processing work is much advanced, which totally avoid the long production cycle and the low production capacity.

4. Ceramic Fiber Board is divided in different series by the temperature, can be widely used as the back lining of industrial furnace and the hot surface of the low temperature furnace. It is one of the guarantees of reaching the energy conservation and the high quality.

![]()

Technical index of ceramic fiber board for steam pipe insulation:

Item | COM | ST | HP | HA | HAZ | HZ |

Working Temperature °C | ≤1000 | 1050 | 1100 | 1200 | 1200 | 1350 |

Classification Temperature °C | 1100 | 1260 | 1260 | 1360 | 1360 | 1430 |

Density kg/m3 | 260 320 | 260 320 | 260 320 | 260 320 | 260 320 | 260 320 |

Permanent linear shrinkage(%)(holding temperature for 24h, density 128kg/m3) | -4(1000°C) | -3(1000°C) | -3(1100°C) | -3(1200°C) | -3(1200°C) | -3(1350°C) |

Thermal conductivity (w/m.k) density 128kg/m3) | 0.085(400°C)0.132(800°C) 0.180(1000°C) | 0.085(400°C)0.132(800°C) 0.180(1000°C) | 0.085(400°C)0.132(800°C)0.180(1000°C) | 0.085(400°C)0.132(800°C) 0.180(1000°C) | 0.085(400°C)0.132(800°C) 0.180(1000°C) | 0.085(400°C)0.132(800°C) 0.180(1000°C) |

Tensile strength (Mpa) density128kg/m3) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

![]()

Refractory ceramic fiber board for steam pipe insulation:

Packaging:PE bags inside,carton box outside

Shiping: About 7-15 days after confirm the order

- Q: What does the rock wool board look like?

- Rock wool board to basalt as a material, after high temperature melting processing into artificial inorganic fibers, with a light weight, thermal conductivity, heat absorption, non-flammable characteristics

- Q: What role does dolomite play in rock wool products?

- Pu hard foam layer can be firmly bonded with the base layer, the adhesive strength can exceed the tear strength of the foam itself, so Pu hard foam and the formation of the base layer, easy to delamination, to avoid the water along the interlayer

- Q: Rock wool products are divided into several categories

- Rock wool with a light weight, non-combustible, small thermal conductivity, sound absorption performance, good chemical stability and so on

- Q: How to judge the quality of rock wool

- Burning performance: Combustion performance refers to all the physical and chemical changes that occur when the building material is burned or in case of fire. This performance is caused by the fire and flame propagation of the material surface, heat, smoke, carbonization, weight loss, and toxicity And other characteristics to measure. The burning performance of the products of rock wool products is zero.

- Q: The difference between rock wool and rock wool

- Yanmian tube is a kind of rock wool insulation material mainly used in the pipeline. After the natural basalt is melted by high temperature, the artificial inorganic fiber is made from the high speed centrifugal equipment, and the special binder and dustproof oil are added. Temperature curing, made into a variety of specifications, different requirements of the rock wool insulation tube

- Q: Rock wool products and aluminum silicate acupuncture blankets are same

- Not a material for insulation, both can be used. The biggest difference is that aluminum silicate acupuncture blanket temperature and insulation effect is better

- Q: Rock wool insulation material fire rating is how much

- Fire protection and noise reduction of the elevator shaft of the building wall, the roof of the insulation, the firewall, the fire door, the large and medium diameter pipes, the small and medium sized storage tanks, the kilns, the thermal power plants, Boilers and other equipment insulation.

- Q: Rock wool board is inorganic composite insulation material

- Rock wool board is inorganic composite insulation material

Send your message to us

Rock Wool Refractory Ceramic Fiber Board for Steam Pipe Insulation Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords