Rock Wool China Low Thermal Conductive Ceramic Fiber Board for High Temperature

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Company Introduction

CNBM (China National Building Material) Group is the largest comprehesnsive building materials group in China that in intergrate scientific research,manufacturing and logistics into one entity.the largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields,CNBM is playing the leading role in the building industry in the country.

CNBM International Corporation is the most import and export platform of CNBM group.With its advanteges,CNBM International are mainly concentrate on Cement,Galss,Iron and Steel,Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

CNBM International Corporation is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. Depending on the support of prodution diveisions and its active staff,CNBM international recached a turnover of USD two billion in 2011. We will carry on the mutual beneficial, create value for our employees, share holders and clients and benefit the whole society in our future development.

product Information

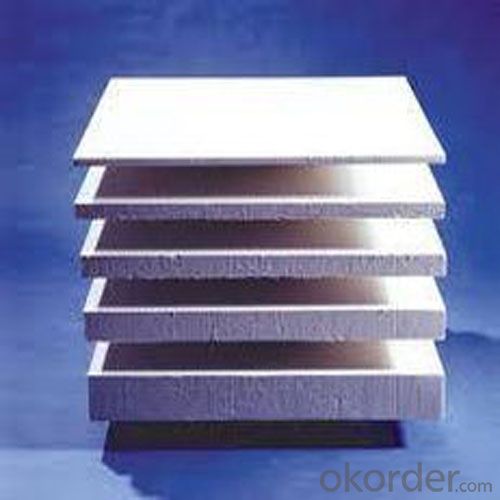

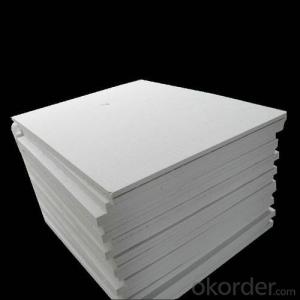

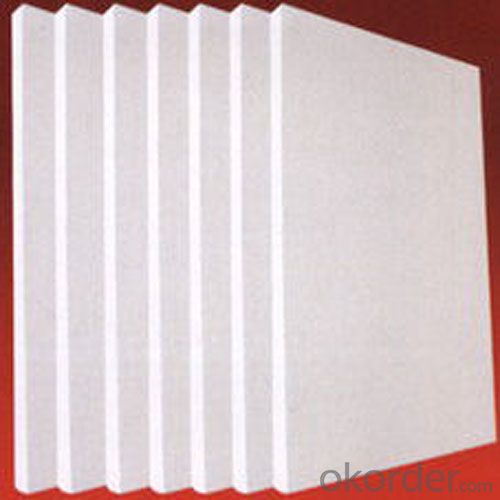

The Ceramic Fiber Board are made of different refractory fiber bulks with excellent chemical stability, organic and inorganic bond

by wet method and vacuum forming processing which is apolitical to many kinds of industries .The fiber board with a

characteristics of hard, flexible,excellent strength and resistance against corrosion

| Model | 1000 Board | 1260 Board | 1400 Board | 1500 Board | 1600Board | 1700Board |

Temperature(℃) | 1000 | 1260 | 1400 | 1500 | 1600 | 1700 |

Color | White | White | White | White | White | White |

Density(kg/m3) | 250~500 | 250~500 | 250~500 | 300~500 | 300~500 | 300~500 |

Tensile Strength(Mpa) | 0.5 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 |

Organic Composition(%) | 8 | 6 | 6 | 6 | 6 | 6 |

Shot ( 212um <) (%) | 10 | 8 | 6 | 1 | 1 | 1 |

Thermal Conductive Kcal/mh℃(W/mK) ,ASTM C201, 190kg/m | ||||||

400℃ | 0.08 | 0.09 | ||||

600℃ | 0.13 | 0.14 | 0.10 | 0.12 | 0.14 | 0.14 |

800℃ | 0.20 | 0.18 | 0.14 | 0.16 | 0.18 | 0.17 |

1000℃ | 0.20 | 0.21 | 0.25 | 0.24 | ||

Chemical Composition : | ||||||

Al2O3(%) | 38 | 42 | 36 | 60 | 70 | 95 |

SiO2(%) | 54 | 52.3 | 49 | 39 | 29 | 4 |

ZrO2(%) | 14 | |||||

Cr2O3(%) | 1.8 | |||||

Fe2O3(%) | 2 | 1 | 1 | 1 | ||

Shrinkage(Less than 200℃*8H) | 2 | 1 | 1 | 1 | ||

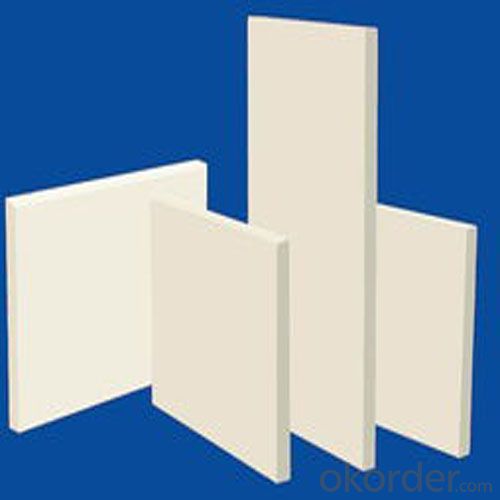

Standard Dimension

Temperature(℃) | Length(mm) | Size(mm) | Thickness(mm) | Density(kg/m3) |

1000℃ | 1200/1000/900 | 1000/600 | 5/6/7/10/15/20/25/30/40/50/100 | 250/280/300/350 |

1260℃ | 1200/1000/900 | 1000/600 | 3/4/5/6/7/10/15/20/25/30/40/50/100 | 250/280/300/350 |

1400℃ | 1200/1000/900 | 1000/600 | 6/10/15/20/25/30/40/50 | 250/280/300/350 |

1500℃ | 1000/900 | 600 | 25/30/40/50 | 350/400 |

1600℃ | 1000/900 | 600 | 25/30/40/50 | 350/400 |

1700℃ | 1000/900 | 600 | 25/50 | 350/400 |

1800℃ | 1000/900 | 600 | 50 | 400 |

Characteristics

Excellent hot strength

Low thermal conductivity

Low heat storage

Excellent handing strength

Thermal shock resistance

High heat reflectance

Excellent corrosion resistance

Excellent thermal stability

Excellent fire protection

Applications

High-temperature kiln and furnace hot face’s lining

Insulating backup

Infra red element supports

Glass tank side & end wall and port neck insulation

Nuclear insulation applications

Hot gas duct linings

Expansion joint seals

Pouring forms for castable

- Q: What does the rock wool board look like?

- The initial development of Hebei Langfang Dacheng in the building is a common type of application for industrial buildings should be consistent with "building insulation materials, the type of application and basic requirements"

- Q: What role does dolomite play in rock wool products?

- What role does dolomite play in rock wool products?

- Q: Rock wool products are divided into several categories

- What are the main categories of rock wool products in interior decoration materials?

- Q: How to judge the quality of rock wool

- Rock wool products, the important content of rock wool products, the density range is kg / m3 100-250 ± 15%, in this density of rock wool board to meet product quality requirements

- Q: The difference between rock wool and rock wool

- Yanmian tube is a kind of rock wool insulation material mainly used in the pipeline. After the natural basalt is melted by high temperature, the artificial inorganic fiber is made from the high speed centrifugal equipment, and the special binder and dustproof oil are added. Temperature curing, made into a variety of specifications, different requirements of the rock wool insulation tube

- Q: Rock wool products and aluminum silicate acupuncture blankets are same

- Not a material for insulation, both can be used. The biggest difference is that aluminum silicate acupuncture blanket temperature and insulation effect is better

- Q: Rock wool insulation material fire rating is how much

- Yanmian, mineral wool and its products are slag and basalt and other natural ore as the main raw material, the high temperature melt fiber, adding the right amount of adhesive processing

- Q: Rock wool board is inorganic composite insulation material

- Insulation material A-level fire is organic meet the inorganic meet resolutely

Send your message to us

Rock Wool China Low Thermal Conductive Ceramic Fiber Board for High Temperature

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords