High Acidity Coefficient Rock Wool Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Production Technique

Rock wool products are manufactured with basalt as main ingredient, made into inorganic fiber in high speed centrifugal machine after melting, A certain amount of cementing agent, rustproof oil, silicon oil is added into the raw material which is made into rock wool board, rock wool blanket, rock wool pipe shell, etc. according to different customer requirement

Pooduct Characteristics

1. Excellent heat preservation, machining and refractory properties.

2. High acidity coefficient, good chemical stability and fiber durability.

3. Excellent deadening property.

Main Products and Size

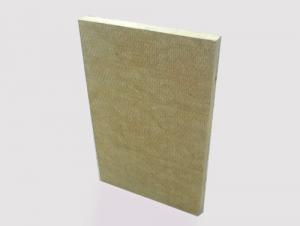

Rock Wool Board

Density: 80-180kg/m3

Thickness: 10-120mm

Size: 1000*600(mm)

Application

Widely used in the heat preservation in various industrial furnaces and pipings in the petroleum, chemical, metallurgical, ship building, textile industries as well as in the heat preservation and deadening in partition wall, hanging ceiling and interiors and exterior walls in the building industry.

3. Good sound absorption property

4. Stable and durable.

5. High acidity coefficient

6. Good chemical stability and fiber durability.

Applications:

It can be widely used as thermal insulation material for high-temperature pipe, tank, equipment and vessel in petroleum, chemical and metallurgy industry. It can also be applied to partition, ceiling and building wall as thermal insulation and sound absorption material in construction industry.

Our certificates:

High-Tech Enterprise Certificate

ISO9001:2008

ISO14001:2004

ISO14024:1999 (China Environmental Labelling)

- Q: What does the rock wool board look like?

- What does the rock wool board look like?

- Q: What role does dolomite play in rock wool products?

- What role does dolomite play in rock wool products?

- Q: Rock wool products are divided into several categories

- Rock wool with a light weight, non-combustible, small thermal conductivity, sound absorption performance, good chemical stability and so on

- Q: How to judge the quality of rock wool

- Appearance and quality: Choose the material surface smooth and beautiful, no stains, no damage to the material

- Q: The difference between rock wool and rock wool

- Yanmian tube with high strength and good flexibility, with a certain pressure, the pleated treatment of rock wool tube with a large drawing strength, not easy to layer, greatly improving the durability of the durability

- Q: Rock wool products and aluminum silicate acupuncture blankets are same

- Rock wool products and aluminum silicate acupuncture blankets are same

- Q: Rock wool insulation material fire rating is how much

- Rock wool products are: rock wool board, rock wool tube, rock wool felt, rock wool insulation and so on

- Q: Rock wool board is inorganic composite insulation material

- Rock wool composite insulation material depends on what you compound the material

Send your message to us

High Acidity Coefficient Rock Wool Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords