Rock Wool Biggest Manufacturers Rockwool Blanket and Boards

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1999 PCS

- Supply Capability:

- 1000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Rockwool

Rock Wool are widely used in public, commercial and residential buildings as well as industrial plants, for applications such as roofing, external wall, partition wall and floating floor to provide fire protection, thermal insulation, acoustic control and condensation control.

Character and Features of Rockwool

650℃, made of stones: ≥85% basalt, 99% hydrophobicity, high compressive strength, corrosion free, Min. density: 40kg/m3 for board

Specification of Rockwool Blanket

Density (kg/m3) | 60-150 |

Size: LxW (mm) | (3000-6000)X600/900 |

Thickness (mm) | 30/40/50/75/100 |

Specification of Rockwool Board

Density (kg/m3) | 40-150 |

Size: LxW (mm) | 1200X600 |

Thickness (mm) | 40/50/75/100 |

Remark:

Other sizes available upon request

Facing materials can be applied upon request

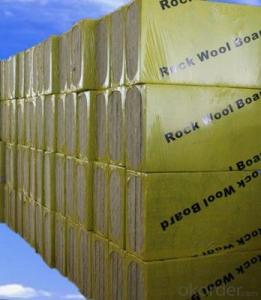

Picture of Rockwool

4. FAQ of Rock Wool Blanket:

What is package? Normal packing: Each roll is wrapped with plastic bag. Special required package like PE BAG and PE SHRINKED BAG can be made with additional charge.

What is MOQ? 1*40HQ

Lead time: 15 days

- Q: What does the rock wool board look like?

- What does the rock wool board look like?

- Q: What role does dolomite play in rock wool products?

- Pu hard foam layer can be firmly bonded with the base layer, the adhesive strength can exceed the tear strength of the foam itself, so Pu hard foam and the formation of the base layer, easy to delamination, to avoid the water along the interlayer

- Q: Rock wool products are divided into several categories

- What are the main categories of rock wool products in interior decoration materials?

- Q: How to judge the quality of rock wool

- Burning performance: Combustion performance refers to all the physical and chemical changes that occur when the building material is burned or in case of fire. This performance is caused by the fire and flame propagation of the material surface, heat, smoke, carbonization, weight loss, and toxicity And other characteristics to measure. The burning performance of the products of rock wool products is zero.

- Q: The difference between rock wool and rock wool

- Yanmian tube is a kind of rock wool insulation material mainly used in the pipeline. After the natural basalt is melted by high temperature, the artificial inorganic fiber is made from the high speed centrifugal equipment, and the special binder and dustproof oil are added. Temperature curing, made into a variety of specifications, different requirements of the rock wool insulation tube

- Q: Rock wool products and aluminum silicate acupuncture blankets are same

- No, rock wool is ore blown wire, aluminum silicate is coke gem

- Q: Rock wool insulation material fire rating is how much

- Yanmian, mineral wool and its products are slag and basalt and other natural ore as the main raw material, the high temperature melt fiber, adding the right amount of adhesive processing

- Q: Rock wool board is inorganic composite insulation material

- Rock wool products are inorganic insulation materials

Send your message to us

Rock Wool Biggest Manufacturers Rockwool Blanket and Boards

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1999 PCS

- Supply Capability:

- 1000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords