QC5-50/10T Electromagnetic Overhead Crane with Hook

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Profile

As a kind of derivative product of overhead crane with hook, the electromagnetic overhead crane with hook can make up the operation that the common overhead crane can not complete the handling or the common overhead crane can complete the lifting and transferring with low efficient. For example, it is used in lifting and transferring ferrous metal, such as steel scrap, scrap iron, pig iron abnormal shape steel plate and others. Because of its convenience, shortcut and efficient, it is widely used in ironworks, steel mill, baiting shop and other sites.

Characteristic

1. There are three kinds of methods for entering the platform of cab:from the side, from the end and from the top.

2. The cab can be installed on the left face or the right face.

3. Lifting capacity includes the dead weight of magnetic disk.

4. The total weight of crane doesn’t include magnetic disk and the weight of accessories.

5. The electromagnetic chunk is suspended under the hook directly, which is in order to dismount and maintenance conveniently.

6. Hoisting brake can be handle in manual way. Thus, the suspending electromagnetic chunk and clogs can be set down quickly and smoothly when it is in fault condition, which can avoid security incidents.

7. The electromagnetic chunk adopts to cable drum to supply power independently.

8. With a protection function of magnetic, it can prevent clog from falling when it is in sudden power failure.

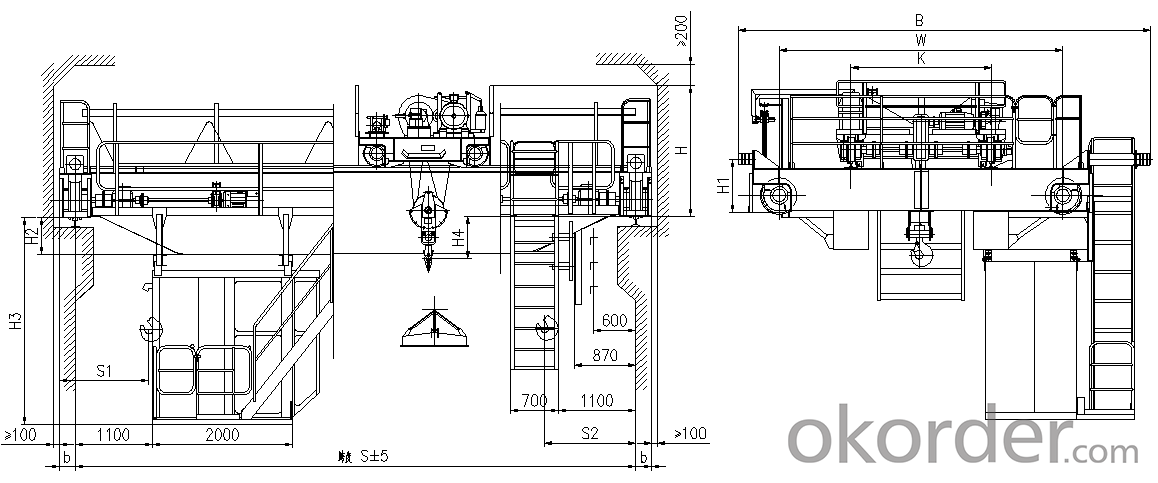

5t~10t Electromagnetic Overhead Crane with Hook

Technical Specifications

Lifting capacity | t | 5 | 10 | |||||||||||||||||||||

Span S | m | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | |||||||

Max.lifting height | m | 16 | 16 | |||||||||||||||||||||

Working classification | A6 | A6 | ||||||||||||||||||||||

speed | Lifting | m/ min | 15.5 | 13.3 | ||||||||||||||||||||

Trolley travelling | 37.2 | 43.8 | ||||||||||||||||||||||

Crane traveling | 115.6 | 116.8 | 115.6 | 116.8 | 112.5 | |||||||||||||||||||

Main dimension | S1 | mm | 1250 | 1500 | ||||||||||||||||||||

S2 | 1500 | |||||||||||||||||||||||

H | 1765 | 1878 | 1928 | |||||||||||||||||||||

H1 | 765 | 800 | 765 | 850 | ||||||||||||||||||||

H2 | -22 | 128 | 228 | 378 | 528 | 678 | 828 | 978 | -22 | 128 | 228 | 378 | 528 | 630 | 780 | 930 | ||||||||

H3 | 2398 | 2548 | 2648 | 2798 | 2948 | 3098 | 3248 | 3398 | 2398 | 2548 | 2648 | 2798 | 2948 | 3050 | 3200 | 3350 | ||||||||

H4 | 69 | 600 | 550 | |||||||||||||||||||||

K | 1400 | 2000 | ||||||||||||||||||||||

W | 3400 | 3550 | 5000 | 4050 | 5000 | |||||||||||||||||||

B | 5058 | 5208 | 6028 | 5708 | 5848 | 6388 | ||||||||||||||||||

b | 230 | |||||||||||||||||||||||

Max.wheel load | kN | 74.5 | 80 | 86.5 | 94 | 101.5 | 113 | 121.5 | 128.5 | 104 | 112 | 121 | 126 | 134 | 146 | 155 | 165 | |||||||

Total power | Kw | 27.8 | 31.8 | 35.5 | 39.5 | |||||||||||||||||||

Recommended steel rail | kg/m | 43kg/m | ||||||||||||||||||||||

Power source | 3-Phase A.C. 50Hz 380V | |||||||||||||||||||||||

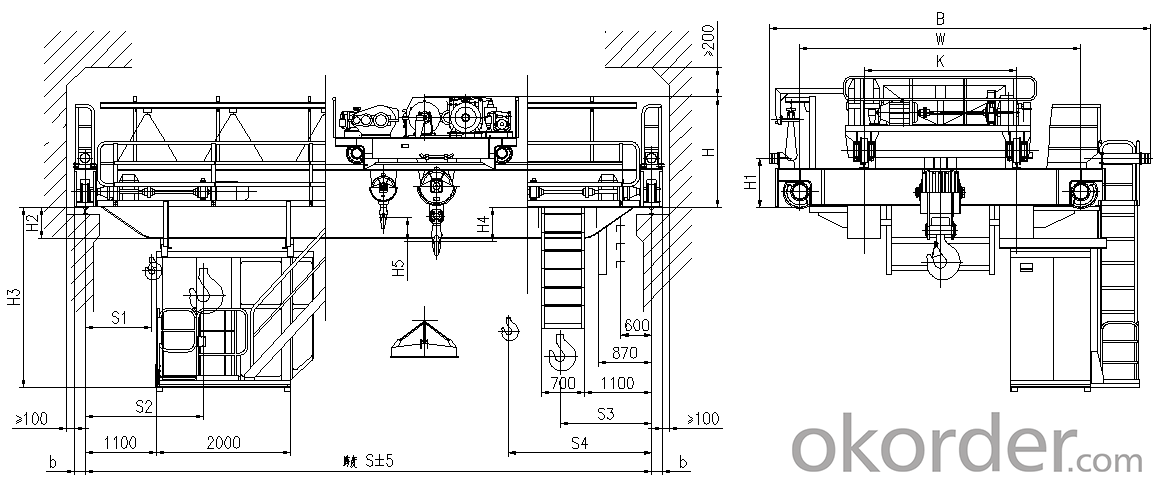

16/3.2t~20/5t Electromagnetic Overhead Crane with Hook

Lifting height | Main hook | t | 16 | 20 | |||||||||||||||||||||||

Auxiliary hook | t | 3.2 | 5 | ||||||||||||||||||||||||

Span S | m | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | ||||||||||

Max.lifting height | Main hook | m | 16 | 12 | |||||||||||||||||||||||

Auxiliary hook | 18 | 14 | |||||||||||||||||||||||||

Classification | A6 | A6 | |||||||||||||||||||||||||

Speed | Main lifting | m/ min | 13 | 9.7 | |||||||||||||||||||||||

Auxiliary lifting | 14.5 | 12.7 | |||||||||||||||||||||||||

Trolley travelling | 44.6 | 44.6 | |||||||||||||||||||||||||

Crane traveling | 112.5 | 101.4 | 112.5 | 101.4 | |||||||||||||||||||||||

Main dimension | S1 | mm | 1040 | 1070 | |||||||||||||||||||||||

S2 | 2460 | 2650 | |||||||||||||||||||||||||

S3 | 1600 | 1700 | |||||||||||||||||||||||||

S4 | 3020 | 3280 | |||||||||||||||||||||||||

H | 2097 | 2099 | 2189 | 2187 | 2099 | 2101 | 2191 | ||||||||||||||||||||

H1 | 815 | 940 | 815 | 940 | |||||||||||||||||||||||

H2 | 82 | 82 | 182 | 242 | 392 | 542 | 692 | 842 | 82 | 86 | 186 | 246 | 394 | 544 | 694 | 844 | |||||||||||

H3 | 2502 | 2502 | 2602 | 2662 | 2812 | 2962 | 3112 | 3262 | 2502 | 2506 | 2606 | 2666 | 2814 | 3964 | 3114 | 3264 | |||||||||||

H4 | 727 | 725 | 635 | 637 | 699 | 697 | 607 | ||||||||||||||||||||

H5 | 768 | 496 | |||||||||||||||||||||||||

K | 2000 | 2000 | |||||||||||||||||||||||||

W | 4400 | 4400 | 5000 | 4400 | 5000 | ||||||||||||||||||||||

B | 6278 | 6188 | 6798 | 6278 | 6188 | 6798 | |||||||||||||||||||||

b | 230 | 260 | 230 | 260 | |||||||||||||||||||||||

Max.wheel load | kN | 146 | 153 | 161 | 174 | 182 | 193 | 204 | 214 | 170 | 177 | 187 | 201 | 210 | 223 | 234 | 245 | ||||||||||

Total power | Kw | 64.5 | 71.5 | 69 | 35.5 | 76 | |||||||||||||||||||||

Recommended steel rail | kg/m | 43kg/m or QU70 | |||||||||||||||||||||||||

Power source | 3-Phase A.C. 50Hz 380V | ||||||||||||||||||||||||||

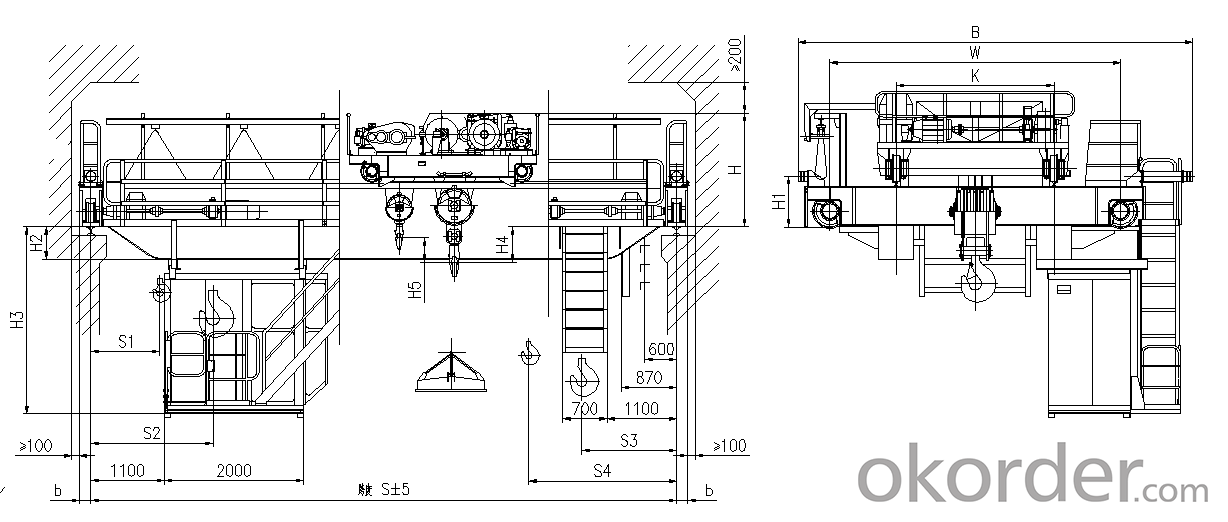

32/5t~50/10t Electromagnetic Overhead Crane with Hook

Lifting height | Main hook | t | 32 | 50 | |||||||||||||||||||||||||

Auxiliary hook | t | 5 | 10 | ||||||||||||||||||||||||||

Span S | m | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | ||||||||||||

Max.lifting height | Main hook | m | 16 | 12 | |||||||||||||||||||||||||

Auxiliary hook | 18 | 16 | |||||||||||||||||||||||||||

classification | A6 | A6 | |||||||||||||||||||||||||||

speed | Main lifting | m/ min | 9.5 | 9.7 | |||||||||||||||||||||||||

Auxiliary lifting | 12.7 | 12.7 | |||||||||||||||||||||||||||

Trolley traveling | 42.4 | 44.6 | |||||||||||||||||||||||||||

Crane traveling | 101.4 | 101.8 | 86.8 | 86.8 | 87.3 | ||||||||||||||||||||||||

Main dimension | S1 | mm | 1070 | 1005 | |||||||||||||||||||||||||

S2 | 2650 | 2785 | |||||||||||||||||||||||||||

S3 | 1700 | 2000 | |||||||||||||||||||||||||||

S4 | 3280 | 3780 | |||||||||||||||||||||||||||

H | 2349 | 2353 | 2483 | 2746 | 2748 | 2754 | |||||||||||||||||||||||

H1 | 905 | 1070 | 1055 | 1090 | |||||||||||||||||||||||||

H2 | 92 | 96 | 246 | 266 | 416 | 566 | 716 | 816 | 71 | 248 | 254 | 404 | 554 | 704 | 804 | 954 | |||||||||||||

H3 | 2512 | 2516 | 2666 | 2686 | 2836 | 2986 | 3136 | 3236 | 2491 | 2668 | 2674 | 2824 | 2974 | 3124 | 3224 | 3371 | |||||||||||||

H4 | 705 | 701 | 571 | 1020 | 1018 | 1012 | |||||||||||||||||||||||

H5 | 790 | 948 | |||||||||||||||||||||||||||

K | 2500 | 2500 | |||||||||||||||||||||||||||

W | 4650 | 4700 | 5000 | 4800 | 5000 | ||||||||||||||||||||||||

B | 6588 | 6608 | 6828 | 6828 | 6858 | 7058 | |||||||||||||||||||||||

b | 260 | 300 | 300 | 300 | |||||||||||||||||||||||||

Max.wheel load | kN | 242 | 256 | 269 | 286 | 298 | 313 | 323 | 335 | 337 | 359 | 379 | 397 | 412 | 429 | 442 | 457 | ||||||||||||

Total power | Kw | 96.6 | 96.3 | 96.3 | 131.5 | 139.5 | |||||||||||||||||||||||

Recommended steel rail | kg/m | QU70 | QU80 | ||||||||||||||||||||||||||

Power | 3-Phase A.C. 50Hz 380V | ||||||||||||||||||||||||||||

Crane span structure

Crane span structure is the main stress component of electromagnetic overhead crane with hook, which adopts double girder and double rail type. The main stress component of it is made up of the main girder and end girder. And, the assisted component of it includes track of trolley, walking platform, handrail, ladder and other attached mental structure.

The main principal weld adopts submerged-arc welding or gas shielded welding. It is tested in accordance with the regulation of general-purpose overhead crane after the it is welded.

The main stress stress material is Q235B. And, the section of the main girder adopts computing method of finite element to analysis and calculate systematically, which aims to assure the main stress materials has enough strength, rigidity and stability in the large.

All of the steel plate has been experienced shot blasting pretreatment, which make it reach Sa2.5 degree standard.

The upper deflection is(0.9~1.4)S/1000 and the position of the max upper deflection must be designed in the middle1/10 range.

The end girder adopts box structure. And. The connection between end girder and main girder is rigid coupling. The end girder can be transported disassembly, which is connected by high strength bolt. The junction plate is positioned by reaming bolt.

The tread of walking board on the crane span structure adopts 3mm thickness skid resistance riffled plate. All aisles are equipped with handrail with 1050mm thickness. And the space between the horizontal overarms is 350 mm. And, on the bottom of the handrail, it is equipped with side wall inner shield, which height is 100mm. Anywhere on the handrail will bear 1kN (100kgf) load from any directions, which will not cause plastic deformation.

The main components are set with lifting lug for lifting, lifting hole and others, which aims to transport and lift conveniently. The position and strength of these lifting lugs and lifting holes have considered the safety and convenience fully.

Lifting mechanism

The main lifting mechanism and auxiliary lifting mechanism are set on the same crane span structure. Each lifting mechanism is equipped with separate drive device. The main lifting mechanism and auxiliary lifting mechanism can complete the lifting independently. Also, it can cooperate with each other to turnover the equipment.

The working principle of the lifting structure: the electric motor is acting. After it go through the reducer, it will drive drum and then, it will complete the handling by steel wire rope twine system.

The electromagnet is suspended under the hook. It is powered by the cable reel on the small frame to control the magnetism of the electromagnet and obtain the adsorption capacity to lift the heavy object.

The braking of the lifting mechanism adopts the electric brake and the brake is stable, safe and reliable.

All parts of the lifting mechanism are compact, easy to maintain. And it is safe and reliable.

Electromagnetic chuck

It adopts a fully sealed structure and has good moisture resistance.

Through the computer optimization design, the structure is reasonable, the self weight is light, the suction is large and the energy consumption is low.

Send your message to us

QC5-50/10T Electromagnetic Overhead Crane with Hook

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords