PVC Pipe Food Grade Non-Smell for Water

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m

- Supply Capability:

- 5000000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Desciption

Type of company | we are the manufacturer | ||||||

Product Items | Standard Straight Hose | ||||||

Straight reducer hose | |||||||

Elbow Silicone hose 45°,60°,90°,135°,180° | |||||||

Intercooler hose | |||||||

Water hose | |||||||

Radiator hose | |||||||

Vacuum hose | |||||||

Turbocharger hose | |||||||

Reduction Silicone hose | |||||||

Hump Silicone hose | |||||||

Reducer Hose | |||||||

Braided Hose | |||||||

U\V\T\S –shaped hose or other special shaped hose can be customized according to your requirement. | |||||||

Specific Details | |||||||

Place of Origin | Hebei China (Mainland) | Material | Silicone Rubber | ||||

Brand Name | LELIJIE | ||||||

Certificate | ISO 9001:2000 | Size tolerance | ±0.3mm | ||||

Producing Technic | moulding and handwork | Tensile Strength | ≥6.5Mpa | ||||

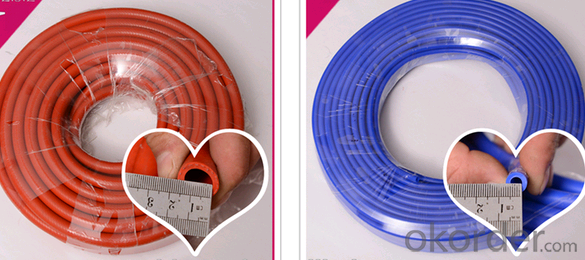

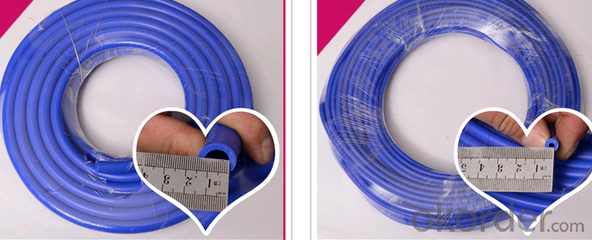

Thickness | 1mm ~ 6mm | Tearing Strength | ≥20.0Kn/Sq.m | ||||

Reinforcement | 4 layers of polyester or nomex | Hardness | 35~80 shore A | ||||

Diameter Range | 6mm~180mm as your customization | Elongation | ≥320 | ||||

Color options | Blue ,white, black, red, green, yellow, grey, orange, etc | Breakdown Voltage | 20-25KV/mm | ||||

special services | Logo designed was available & OEM hose was allowed | Working Temperature | -60 ~ 300 °C | ||||

Usage | Turbo charge, coolant, , Air inlet/exhaust, Radiator, Heater system | Explosive Pressure | 5.5~9.7MPa | ||||

Application | Car, Truck, Bus, Racing car, Heavy Machine, Engineering, Vessel etc | Support Pressure | 0.3 to 0.9MPa | ||||

Our Service

We can offer OEM Services

We can provide FREE SAMPPLE for our customers

We can crimp hose assembly for our customers.

We welcome clients to visit our factory leading to better understanding of our production

FAQ

Q1. Do you produce smooth or cloth wrapped cover?

A. Both, we can produce both cover, which depends on customer’s request.

Q2. Do you produce embossed marking?

A. Yes, we do provide embossed and printing markings with different color.

Q3. Can you produce product with my own brand?

A. Yes, we have been offering OEM services for 20 years.

Q4. Does your product have different color hose?

A. Yes, we currently provide black, grey, red, blue and yellow.

Q5. How long does my order take to be delivered?

A. It usually takes 5 to 30 days, which generally depends on the quantity of your order and our storage.

- Q: The small hose attached to the grease gun is coarse or fine at the joint

- For sealing, according to the maze principle, the smaller the pitch, the number of threads, that is, the more layers, the better the sealing effect, not easy to leak oil, significantly better than the rental thread.

- Q: How long is the service life of the gas hose?

- The service life of the hose is two years. It is recommended to change it once a year,

- Q: The basic buret is a rubber tube is inlaid with a glass bead to replace glass piston. Why this burets cannot be used to install Potassium Permanganate solution?

- Are made of glass, acid burette glass piston burette, no piston, just at the tip of a rubber tube, rubber tube with glass beads, glass or the lower beak. Why not the same because of acid burette, glass and alkali reaction, generate silicate, sticky, if it is very easy to use acid burette, the hole is blocked, damaged burets.

- Q: What kind of material is medical rubber tube?

- Silicone rubber, of course, is environmentally friendly, non-toxic, harmless, such as high-pressure sealing ring in the pot. First of all, to the human body non-toxic first.

- Q: How do you remove the burrs on the rubber joint quickly?

- The thickness of the rubber joint burr than the thickness of the product is much thinner, so brittle speed than the speed burr brittle products quickly, in burr brittle and brittle products without this period of time can be hit by projectile projectile with frozen products deburring machine, thereby removing burrs in embrittlement.

- Q: How to remove the smell of gasoline in the car?

- The leakage of the gasoline pipe usually occurs at the interface between pipes. Open the engine compartment lid and visually judge that if the interface leaks, after a period of time, the surface will absorb dust and form oil sludge.Measures: check the gasoline pipe regularly, tighten and repair the interface in time, replace the gasket and so on.

- Q: Acid burette and how to distinguish the basic buret

- Alkali: rubber tubes. Acids: glass tubes (remember: NaOH and glass reactions. So rubber)

- Q: Excuse me, how can I get waterproof wires in the water?

- The wire connector that enters the water can be "waterproof" and "waterproof"Waterproof joints, as the name suggests, can be applied to the water environment, providing safe and reliable connector joints. For example: LED street lights, lighthouses, cruise ships, industrial equipment, sprinkler and so on, all need to use waterproof joints.

- Q: What kind of material does hose screw protection cover have? What are their advantages and disadvantages?

- The utility model relates to a pipe protecting sleeve, which is a new product replacing the traditional metal protecting spring used for the protection of traditional rubber hoses. Alias: hose sheath, rubber tube outside protection special nylon spiral sheath, etc..

- Q: How do I get the hose for the gas cooker?

- Stainless steel bellows, stainless steel bellows, with a service life of ten years. The outside of the tube is covered with a layer of yellow plastic. All the inside are made of stainless steel. The ends of the pipe are connected with the mouth. There is also a black rubber piece, which is connected with the valve. After the tightening, the rubber sheet will expand and prevent the depression. Some live in a building or a cottage residents, plastic hose home is often a mouse or other insect bite, the use of stainless steel tube after it will not happen.

Send your message to us

PVC Pipe Food Grade Non-Smell for Water

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m

- Supply Capability:

- 5000000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords