Packaging Tape Dollar General PVC Electrical Insulation Tape Single Sided Adhesive

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of PVC Tape

PVC tapes are made of soft pvc film coated with rubber pressure-sentitive adhesive.

Application of PVC Tape

PVC tapes are widely used in auto harness, wrapping of wire, and insulation protection. It is the main insulation material of automobilehousehold electrical apparatus.

Advantage of PVC Tape

Corrosion protection for metal piping systems above and below ground.

Corrosion protection for fittings and joints on mill coated pipe.

Corrosion protection of electrical conduit & fittings.

Resists corrosive action by salt water, soil acids, alkalies and salts.

Prevents dielectric corrosion between buried steel pipe and soil minerals.

Pictures of PVC Tape

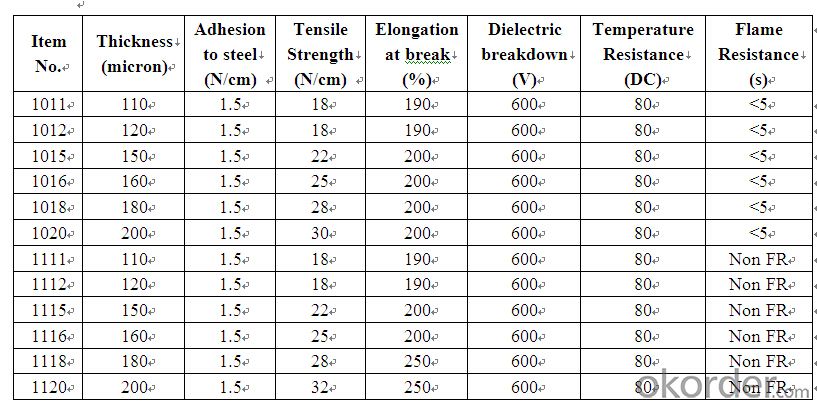

Specification of PVC Tape

FAQ

1. What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

2. What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

3. How many carriers does your double sided adhesive tapes have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

4.Can you accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

- Q: Is packaging tape safe for use on children's toys or products?

- Directly using packaging tape on children's toys or products is not recommended. Although packaging tape is commonly used for sealing packages, it is not intended or tested for contact with children's skin or for use on items that may come in contact with their mouths or eyes. To ensure the safety of children, toys and products for children must adhere to specific safety regulations and guidelines. It is crucial to follow the manufacturer's instructions and use materials specifically designed for children's toys and products, such as non-toxic adhesives or child-safe tapes.

- Q: Is packaging tape resistant to mold or mildew?

- Yes, packaging tape is generally resistant to mold or mildew.

- Q: How does packaging tape perform on non-porous surfaces?

- Packaging tape has been engineered to stick effectively to a wide variety of surfaces, including those that are non-porous. When it comes to non-porous surfaces like glass, metal, plastic, or sealed wood, their smooth and impermeable nature can pose a challenge for adhesives to adhere properly. However, packaging tapes are specifically crafted with strong adhesive properties that enable them to perform efficiently even on non-porous surfaces. Once applied to a non-porous surface, packaging tape creates a strong bond thanks to its high tackiness and cohesive strength. The tape's adhesive is specially formulated to possess excellent adhesion properties, guaranteeing a dependable seal. It adheres firmly to the surface, establishing a secure bond that resists peeling or lifting. Furthermore, packaging tapes often feature special attributes like acrylic or hot melt adhesives, which further enhance their performance on non-porous surfaces. Acrylic adhesive tapes are renowned for their exceptional initial tack, rapid adhesion, and long-term durability. They can withstand changes in temperature, humidity, and exposure to UV radiation, making them suitable for a variety of environments. On the other hand, hot melt adhesive tapes offer superior bonding strength and are perfect for heavy-duty applications, ensuring a robust hold on non-porous surfaces. Additionally, packaging tapes are typically constructed from durable materials such as polypropylene or polyester, which are resistant to tearing or stretching. This further enhances their performance on non-porous surfaces, as they can endure the rigors of shipping and handling without compromising their adhesive properties. In conclusion, packaging tape is specifically designed to excel on non-porous surfaces. Its strong adhesive properties, specialized adhesive formulations, and durable materials allow it to create a dependable seal on surfaces like glass, metal, plastic, or sealed wood. Whether it's for packaging, shipping, or general use, packaging tape is a reliable choice for securing items on non-porous surfaces.

- Q: Can packaging tape be recycled?

- Packaging tape can indeed be recycled, but its recyclability depends on the type of tape and the recycling facilities in your area. The commonly used clear or brown polypropylene tape, for example, cannot be recycled along with regular paper or plastic waste. However, certain recycling centers do accept specific types of tapes for recycling, such as those made from paper or with water-based adhesives. It's crucial to contact your local recycling center to determine their policy on packaging tape recycling and any specific requirements they may have. Furthermore, taking the tape off cardboard boxes before recycling them can enhance the recycling process. If recycling is not feasible, it is recommended to either reuse the packaging tape or dispose of it properly in the regular trash.

- Q: How do I prevent packaging tape from getting tangled?

- To prevent packaging tape from getting tangled, ensure that the tape roll is placed on a dispenser or a stationary surface with the sticky side facing down. Additionally, avoid pulling the tape too quickly or at an angle, as this can cause it to twist and tangle. Taking these precautions will help maintain the tape's smooth flow and prevent any frustrating tangles.

- Q: Can packaging tape be used for sealing furniture or home goods?

- Yes, packaging tape can be used for sealing furniture or home goods. Packaging tape is designed to provide a secure and strong seal, making it suitable for various purposes including sealing boxes and packages. When used on furniture or home goods, packaging tape can help keep the item protected during transportation or storage. It is important to ensure that the tape is applied properly and that it does not damage the surface or leave any residue. Additionally, depending on the weight and size of the item, it might be more appropriate to use specialized tapes or techniques for sealing furniture or home goods to ensure maximum protection.

- Q: Can packaging tape be used for sealing envelopes?

- Indeed, sealing envelopes can be accomplished with packaging tape. While its primary purpose is to securely seal boxes and packages, packaging tape can also effectively seal envelopes. Its formidable adhesive properties guarantee a sealed envelope throughout its journey. Nonetheless, it is worth mentioning that packaging tape may not be the most visually appealing option for sealing envelopes, as it tends to be wider and less transparent compared to conventional choices like glue sticks or clear tape.

- Q: What are the benefits of using tamper-evident packaging tape?

- Several advantages are offered by tamper-evident packaging tape for both businesses and individuals. Firstly, it adds an extra layer of security by clearly indicating if a package has been tampered with. This helps to prevent theft, unauthorized access, or tampering of valuable or sensitive items during transit or storage. Moreover, the use of tamper-evident packaging tape boosts the trust and credibility of a business. By employing such tape, companies can assure their customers that their products have not been tampered with and are delivered in their original state. This is especially crucial for industries like pharmaceuticals, food, and electronics, where ensuring product safety and integrity is of utmost importance. Furthermore, tamper-evident packaging tape acts as a deterrent for potential tampering. The visible and conspicuous markings on the tape serve as a warning to potential thieves or unauthorized individuals, discouraging them from attempting to tamper with packages. Another benefit is the simplicity and convenience offered by tamper-evident packaging tape. It can be quickly and easily applied to packages of various sizes and shapes, providing a dependable sealing solution that is resistant to tampering attempts. Additionally, the tape is typically designed to leave behind unmistakable evidence of tampering, making it easy to detect if a package has been compromised. Lastly, the use of tamper-evident packaging tape aids businesses in complying with regulatory requirements. Many industries have specific guidelines and regulations in place regarding product safety and security. By utilizing tamper-evident tape, companies can demonstrate their commitment to meeting these standards and ensure the integrity of their products throughout the supply chain. In conclusion, the advantages of tamper-evident packaging tape include heightened security, increased trust, deterrence of tampering, ease of use, and regulatory compliance. By investing in this straightforward yet effective sealing solution, businesses and individuals can safeguard their packages, ensure the integrity of their products, and provide peace of mind to customers.

- Q: Is packaging tape safe to use on painted surfaces?

- Packaging tape is generally safe to use on painted surfaces, but there are a few factors to consider. Firstly, it is important to ensure that the paint is fully cured before applying any tape. This typically takes around 30 days, depending on the type of paint used. Applying tape to fresh or uncured paint can cause damage when the tape is removed. Secondly, the type of tape used can also make a difference. Most packaging tapes are designed to be easily removable without leaving residue or causing damage to surfaces. However, some low-quality tapes or tapes with strong adhesives may leave behind sticky residue or even peel off the paint when removed. It is recommended to use high-quality packaging tape that is specifically labeled as safe for painted surfaces. To be on the safe side, it is always a good idea to test the tape on a small, inconspicuous area of the painted surface before applying it extensively. This will help you ensure that the tape does not cause any damage or leave residue behind. If there are any concerns, it is advisable to consult the manufacturer's instructions or seek professional advice. Overall, when used properly and on fully cured paint, packaging tape should be safe to use on painted surfaces. However, it is important to exercise caution and choose the right tape to prevent any potential damage.

- Q: How does packaging tape perform on low-friction surfaces?

- Packaging tape generally does not perform well on low-friction surfaces. Its adhesive may struggle to stick firmly, leading to reduced adhesion and the tape easily peeling off. In such cases, it is recommended to use alternative adhesive solutions or methods specifically designed for low-friction surfaces to ensure proper packaging and sealing.

Send your message to us

Packaging Tape Dollar General PVC Electrical Insulation Tape Single Sided Adhesive

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords