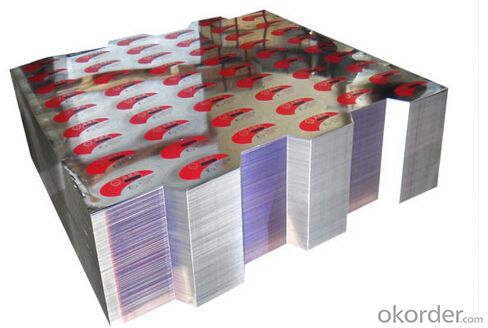

PRINTED SHEET

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are one of the main printing and coating plant in the North China, very close to the Tianjin sea port. We can undertake all kinds of tinplate, cold plate and other processing services. We have regular business with the state legislature, Kamei and other large companies by providing printing produces. Through so many years development, we have stable customers in the Southeast Asia, like Singapore and Vietnam and continuous orders. We can do Color printing, Offset printing, peritoneum, glazing and lithographic printing. Products include chemicals and food packaging used tinplate or tin free steel(TFS).

Features:

- Chemical and Corrosion Resistant

- Easily Fabricated or Welded

- Cost Effective

- Durable and flame retardant

- Excellent for outdoor exposure.

- Paintable. Weather resistant.

- High tensile, compressive, and flexural strength.

Our machines are from Japan with high quality. We have high quality control to each product.

Company management system is healthy, operational mechanism running good. After years of effort, base on the introduction, absorption, digestion of the advanced technology, techniques, equipment, we gradually set up the unique production process and technical support system which is market need-oriental and suite to the Chinese condition.

In the fierce market competition, our company will continue to pursue the excellence quality and outstanding service, and provide more and better service and service to meet customers demand on metal package home and abroad.

- Q: What are the typical manufacturing processes for tinplate products?

- The typical manufacturing processes for tinplate products include coil preparation, coil cleaning, annealing, coating, temper rolling, cutting, and forming.

- Q: Tin cans and tin cans, which is good?

- I think this question is not asked to tin tin, chrome tin and galvanized tin which is the best? Of course, the best is galvanized iron. The second is the tin tin, followed by chrome tin, iron box is made finally.

- Q: What are the main components of tinplate?

- The main components of tinplate are steel and a thin layer of tin.

- Q: What are the advantages of using tinplate for automotive parts?

- Tinplate offers several advantages for automotive parts. Firstly, it provides excellent corrosion resistance, ensuring durability and long-lasting performance even in harsh environments. Secondly, it offers high strength and rigidity, making it suitable for various automotive applications that require structural integrity. Additionally, tinplate is lightweight, contributing to fuel efficiency and reducing the overall weight of the vehicle. Lastly, it allows for easy shaping and forming, enabling complex designs and customization options for automotive components.

- Q: How is tinplate stored?

- Tinplate is typically stored in dry and well-ventilated areas to prevent moisture and rusting. It should be stacked on pallets or shelves, away from direct sunlight and sources of heat. Additionally, it is important to ensure proper labeling and organization to facilitate easy access and inventory management.

- Q: Can tinplate packaging be used for pet care products?

- Yes, tinplate packaging can be used for pet care products. Tinplate is a durable and versatile material that can provide excellent protection for various products, including pet care items such as food, treats, and grooming products. It offers airtight and moisture-resistant properties, ensuring the freshness and quality of the contents. Additionally, tinplate packaging can be designed with visually appealing graphics, enhancing the overall presentation and shelf appeal of pet care products.

- Q: Can tinplate be used for aerosol packaging?

- Yes, tinplate can be used for aerosol packaging. Tinplate is a common material choice for aerosol cans due to its strength, durability, and resistance to corrosion. It provides a protective barrier against moisture and oxygen, ensuring the integrity of the aerosol product. Additionally, tinplate can be easily formed into various shapes and sizes required for aerosol packaging.

- Q: What are the advantages of using tinplate for HVAC components?

- There are several advantages to using tinplate for HVAC components. Firstly, tinplate is highly resistant to corrosion, making it suitable for applications in humid environments or those involving exposure to moisture. Secondly, tinplate offers excellent heat resistance, ensuring the durability and longevity of HVAC components even under high temperatures. Additionally, tinplate is lightweight, making it easier to handle and install, while still maintaining its strength and structural integrity. Lastly, tinplate is a cost-effective option, providing a balance between performance and affordability for HVAC systems.

- Q: What are the main factors influencing the growth of the tinplate industry?

- The main factors influencing the growth of the tinplate industry include the demand for packaged food and beverages, growth in the automotive industry, increasing urbanization and industrialization, technological advancements in manufacturing processes, and government initiatives promoting sustainability and recycling.

- Q: What are the different closure options for tinplate packaging?

- The different closure options for tinplate packaging include twist-off caps, lug caps, screw caps, and press-on caps.

Send your message to us

PRINTED SHEET

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords