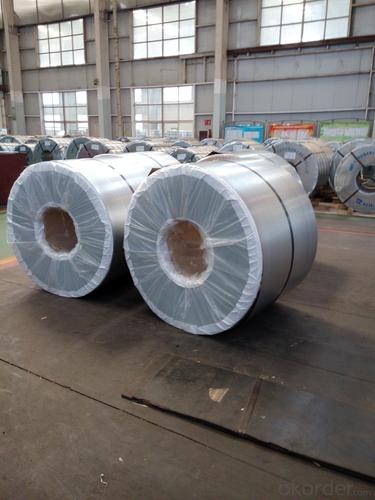

PRIME GOOD QUALITY Tinplate ETP

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We have been producing tinplate material professionally and providing related service for decades years. Now we have been exporting our material to the world. Please kindly contact us to meet your needs for ETP materail.

Below is the specification we currently do:

1. Standard: GB/T 2520-2000, JIS G3303-2002 and DIN EN 10203-1991

2. Raw material: MR, SPCC

3.Thickness: 0.18 to 0.50mm

4. Width: 260 to 980mm

5. Coil diameter: ID 420mm or 508mm

6. Temper grade: T2, T3 and T4

7. Tin coating: ordinary 2.8 or 2.8g and 5.6g or 5.6g, can produce according to customer's requests

8. Applications: paint, chemical and other usage can make battery, electric cable and other industries

9. Package: anti-rust paper, corner protected. Sheets or coils according customer's request.

Standard for Temper:

code | Chinese Stardard | Japaness Standard | American Standard | European Standard | International Standard |

| GB/T 2520-2000 | JIS G3303-2002 | ASTM A623M-2002 | DIN EN 10203-1991 | ISO 11949-1995 |

T-2 | TH52+SE | T-2 | T-2(53) | T52 | TH52+SE |

T-2.5 | TH55+SE | T-2.5 |

|

| TH55+SE |

T-3 | TH57+SE | T-3 | T-3(T57) | T57 | TH57+SE |

T-3.5 |

|

|

|

|

|

T-4 | TH61+SE | T-4 | T-4(T61) | T61 | TH61+SE |

Surface of tinplate:

Marks | Surface state | Characteristics |

B | Bright rough | Glazed surface obtained after melting treatment of electrotinned smooth raw material strip featuring certain oriented rubstone figure. |

R | Stone rough | Glazed surface obtained after melting treatment of electrotinned raw material strip featuring certain oriented rubstone figure. |

S | Silver rough | Glazed surface obtained after melting treatment of electrotinned raw material strip with rough matt surface. |

- Q: What are the advantages of using tinplate for jewelry?

- One advantage of using tinplate for jewelry is its affordability. Tinplate is a cost-effective material compared to precious metals such as gold or silver, making it accessible to a wider range of consumers. Additionally, tinplate is lightweight, making it comfortable to wear for extended periods. It also offers versatility in design, allowing for intricate and detailed jewelry pieces. Lastly, tinplate is highly resistant to corrosion, ensuring the longevity and durability of the jewelry.

- Q: How does tinplate packaging contribute to product differentiation?

- Tinplate packaging contributes to product differentiation by providing a unique and attractive look that distinguishes a product from its competitors. The use of tinplate allows for creative and eye-catching designs, which can effectively communicate the brand's identity and create a memorable impression on consumers. Additionally, tinplate packaging offers durability and protection, ensuring that the product remains in good condition throughout its shelf life. This enhances the overall perceived value of the product and sets it apart from alternatives, thus contributing to product differentiation.

- Q: How does tinplate affect the overall barrier properties of packaging?

- Tinplate enhances the overall barrier properties of packaging by providing a protective layer that effectively prevents the transfer of oxygen, moisture, and light. This barrier helps to preserve the quality, freshness, and shelf life of the packaged product, ensuring its integrity and safety.

- Q: How is tinplate protected during transportation and storage?

- Tinplate is protected during transportation and storage through various measures such as applying protective coatings, using packaging materials like wooden crates or pallets, and ensuring proper handling and storage conditions to prevent damage from moisture, corrosion, and physical impact.

- Q: What are the different tinplate grades available in the market?

- There are several different tinplate grades available in the market, including prime quality, secondary quality, and surplus quality. Prime quality tinplate is the highest grade and is typically used for food packaging and other high-quality applications. Secondary quality tinplate may have minor imperfections but is still suitable for a wide range of applications. Surplus quality tinplate is typically sold at a lower price and may have more noticeable imperfections, making it suitable for less demanding uses.

- Q: Can tinplate be used for packaging industrial chemicals?

- Yes, tinplate can be used for packaging industrial chemicals. Tinplate is a type of steel coated with a thin layer of tin, providing it with excellent corrosion resistance and durability. These properties make tinplate suitable for packaging industrial chemicals that may be corrosive or reactive. Additionally, tinplate is also impermeable to light, moisture, and oxygen, providing further protection to the chemicals.

- Q: What are the limitations of printing on tinplate?

- There are several limitations to printing on tinplate. Firstly, tinplate is not a very smooth surface, which can affect the quality of printed images and text. Additionally, the printing process on tinplate requires specialized inks and equipment, making it more costly and time-consuming compared to printing on other materials. Furthermore, tinplate is prone to scratching and chipping, which can damage the printed design. Lastly, the printing options on tinplate are somewhat limited, as it cannot accommodate intricate or highly detailed designs as well as other printing mediums.

- Q: Can tinplate be used for packaging confectionery products?

- Yes, tinplate can be used for packaging confectionery products. Tinplate is a commonly used material for food packaging due to its durability, resistance to corrosion, and ability to maintain product freshness. It provides a safe and secure packaging option for confectionery items, ensuring a longer shelf life and preserving the quality of the products.

- Q: Can tinplate be welded?

- Yes, tinplate can be welded. Welding tinplate involves joining two or more pieces of tinplate together using various welding techniques such as spot welding or seam welding.

- Q: What are the health and safety concerns associated with tinplate?

- Tinplate, a thin steel sheet coated with a layer of tin, can present some health and safety concerns. One primary concern is the potential for tin contamination in food or beverage products stored in tinplate cans. Prolonged exposure to high levels of tin can lead to health issues such as gastrointestinal problems, kidney damage, and even neurological disorders. Additionally, the manufacturing process of tinplate involves the use of chemicals and substances that may pose risks to workers, such as potential inhalation hazards or skin irritation. Proper handling, storage, and adherence to safety guidelines are crucial to minimize health and safety risks associated with tinplate.

Send your message to us

PRIME GOOD QUALITY Tinplate ETP

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords