Wrench for Plastic Pipe Fittings - PPR Reducing Coupling Reduction External/Internal

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Material: PP-R

Technics: injection

Type: Coupling

Place of Origin: China (Mainland)

Model Number: DS-001

- Connection: Welding

Shape: Reducing

Head Code: round

color: green/ grey/ white

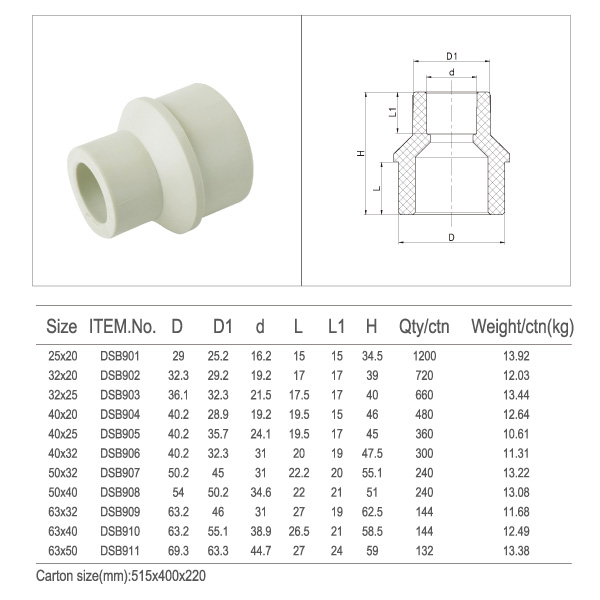

Specifications

Standard: DIN8077/8078

Material: R200P from Korea

Size: DN20~63

Color: Green, White, Grey, Blue

Packaging & Delivery

Packaging Details: PE bag and carton

Delivery Detail: 10 Days

Our Advantages:

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden installation

9) Recyclable, environment-friendly, accords with GBM standards

Applications

> Distribution for cool and hot water;

> Duct for drinkable water system;

> Pipes for kinds of high-temperature and low-temperature heating system;

> Pipes for heating and coolling settings in solar energy system;

> Connecting pipe for air conditioners.

- Q: What are the common installation methods for plastic pipe fittings?

- The common installation methods for plastic pipe fittings include solvent welding, threaded connections, and compression fittings.

- Q: Can plastic pipe fittings be used for radiant cooling systems?

- Yes, plastic pipe fittings can be used for radiant cooling systems. Plastic pipe fittings, such as PEX (cross-linked polyethylene) fittings, are commonly used in radiant cooling systems due to their durability, flexibility, and ease of installation. Additionally, plastic fittings are resistant to corrosion and have low thermal conductivity, making them suitable for use in cooling systems where condensation may occur.

- Q: About plastic drain pipe expansion joint

- The setting of the expansion joint of the plastic drain pipe is generally determined according to the requirements of the design document or the type of pipe, the mode of joint and the position of the environment.

- Q: Can plastic pipe fittings be used for chemical dosing systems?

- Yes, plastic pipe fittings can be used for chemical dosing systems.

- Q: Are plastic pipe fittings resistant to impact damage?

- Yes, plastic pipe fittings are generally resistant to impact damage. They are designed to withstand moderate impacts without cracking or breaking. However, the degree of impact resistance may vary depending on the type and quality of the plastic used in the fittings.

- Q: Are plastic pipe fittings resistant to algae and fungi growth?

- Yes, plastic pipe fittings are generally resistant to algae and fungi growth due to their non-porous nature and the absence of organic materials that provide a suitable environment for these organisms to thrive.

- Q: Can plastic pipe fittings be used for marine applications?

- Yes, plastic pipe fittings can be used for marine applications. They are often made from materials such as PVC (polyvinyl chloride) or CPVC (chlorinated polyvinyl chloride), which are resistant to corrosion and can withstand the harsh conditions of marine environments. Additionally, plastic fittings are lightweight, easy to install, and cost-effective, making them a popular choice for various marine applications such as plumbing systems, water supply, and drainage systems.

- Q: Are plastic pipe fittings suitable for pharmaceutical manufacturing?

- Yes, plastic pipe fittings can be suitable for pharmaceutical manufacturing. They offer various advantages such as chemical resistance, low cost, easy installation, and flexibility. However, it is essential to ensure that the chosen plastic material and manufacturing processes comply with the industry's strict quality and safety standards to prevent any potential contamination risks.

- Q: Can plastic pipe fittings be used for CO2 capture systems?

- Yes, plastic pipe fittings can be used for CO2 capture systems. Plastic fittings, such as PVC or polypropylene, are commonly used in various industrial applications including CO2 capture systems. They offer several advantages such as corrosion resistance, cost-effectiveness, and ease of installation. However, it is essential to ensure that the specific plastic material and fittings chosen can withstand the pressure, temperature, and other specific requirements of the CO2 capture system.

- Q: How do plastic pipe fittings compare to ductile iron fittings?

- Plastic pipe fittings offer several advantages over ductile iron fittings. Plastic fittings are typically lighter, easier to handle, and require less labor to install. They are also resistant to corrosion and chemicals, making them suitable for a wide range of applications. Additionally, plastic fittings are more cost-effective and have a longer lifespan compared to ductile iron fittings.

Send your message to us

Wrench for Plastic Pipe Fittings - PPR Reducing Coupling Reduction External/Internal

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords