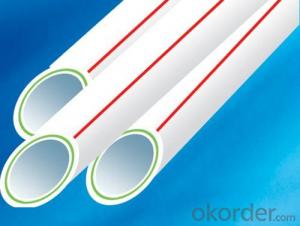

Plastic Waste Pipes and Fittings PPR Reducers for Landscape Irrigation New Drainage System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introductation of Products

Place of Origin: Henan, China (Mainland)

Model Number: PE100

Material: PE

Specification: DN 20-mm~DN1200mm

Length: According to customer requirement

Thickness:SDR11/13.6/17

Standard: ISO

Color: many colors

Product name: Plastic Pipe

Application: house and garden

Usage: Family Decoration Industry

Certification: ISO Certificate

Feature: Lightweight

Size: Customized Size

Type: Round Pipe

Name: HDPE Plastic Pipe

Connection: Butt Fusion

Specification

1.Material : | PPR |

2.Color: | White, Gray, Green, or as you required. |

3.Size: | 20-110mm |

4.Logo: | CMAX or Customized |

5.MOQ | 500pcs |

6.Samples Time: | (1) 4-5days-If you want to customize your logo. |

(2) 1day-For our existing samples for reference. | |

7.OEM Accepted | Yes |

8.Certification available: | Yes |

9.Packing Details: | Weaving Bag |

10.Production Capacity: | 5,000,000pcs Per month. |

11.Payment Term: | (1) L/C,T/T,D/P |

Applications Of PPR Pipe (white, gray):

1) Cold and hot water supply systems for civil and industrial constructions, e.g. in residential buildings, hospitals, hotels, school and office buildings, ship building

2) Drinking water systems and food industry pipe works

3) Central air conditioning system

4) Irrigating system for gardens and green houses

5) Public and sport facilities such as swimming pools and stadiums

6) For rainwater utilization systems

Packaging Details:

1. Large carton: 515 x 400x 220 Cubage: 0.04532 M3

Small carton: 390x255x250 Cubage: 0.0248 M3

2. PE poly bag+ carton Delivery Detail: 15 days/ 20" container; 25 days/ 40HQ

FAQ

Q1: How Can I Get A Sample?

A1: You can get samples by communicate with our export sales.

Q2: How Long Is Delivery?

A2: Delivery time will be30-45days according to order quantity.

Q3: What Is The MOQ?

A3: MOQ depends on different items.

Q4: What Is Our Normal Payments Terms?

A4: Our normal payment terms now is: T/T, L/C or western union, pay

- Q: Can plastic pipe fittings be used in irrigation pivot systems?

- Yes, plastic pipe fittings can be used in irrigation pivot systems. They are commonly used due to their durability, resistance to corrosion, and ease of installation. However, it is important to ensure that the plastic fittings are compatible with the specific requirements of the irrigation system and that they meet the necessary industry standards.

- Q: Are plastic pipe fittings resistant to hydraulic fluids?

- Yes, plastic pipe fittings can be resistant to hydraulic fluids, depending on the type of plastic used. Some plastics, such as PVC (Polyvinyl Chloride) and CPVC (Chlorinated Polyvinyl Chloride), are generally resistant to hydraulic fluids. However, it is important to consult the manufacturer's specifications and guidelines to ensure the specific plastic pipe fittings chosen are suitable for use with hydraulic fluids.

- Q: Can plastic pipe fittings be used in greenhouse systems?

- Yes, plastic pipe fittings can be used in greenhouse systems. They are commonly used due to their durability, resistance to corrosion, and affordability. Plastic pipe fittings also offer easy installation and provide good water flow, making them suitable for greenhouse irrigation systems.

- Q: Are plastic pipe fittings suitable for compressed gas applications?

- No, plastic pipe fittings are not suitable for compressed gas applications as they can become brittle and fail under high pressure, posing safety risks. Metal pipe fittings are better suited for these applications.

- Q: Are plastic pipe fittings easy to remove?

- Yes, plastic pipe fittings are generally easy to remove. They are designed to be easily installed and uninstalled without requiring specialized tools or excessive force.

- Q: Can plastic pipe fittings be used for geothermal heating systems?

- Yes, plastic pipe fittings can be used for geothermal heating systems. Plastic pipe fittings are commonly used in these systems due to their durability, corrosion resistance, and flexibility. They are able to withstand the high temperatures and pressures associated with geothermal heating systems, making them a suitable choice for this application.

- Q: Can plastic pipe fittings be used for industrial applications?

- Yes, plastic pipe fittings can be used for industrial applications. Plastic pipe fittings are durable, lightweight, and resistant to corrosion, making them suitable for various industrial settings. They are commonly used in industries such as chemical processing, water treatment, and HVAC systems. Additionally, plastic pipe fittings can offer cost savings compared to traditional metal fittings, making them a popular choice in many industrial applications.

- Q: Are plastic pipe fittings suitable for water parks and pools?

- Yes, plastic pipe fittings are suitable for water parks and pools. They are durable, resistant to corrosion, and can withstand constant exposure to water and chemicals. Additionally, plastic pipe fittings are lightweight, easy to install, and cost-effective, making them a popular choice for water park and pool applications.

- Q: How is the building material, plastic pipe and sewer made? Where are the machines and how much is the selling price?

- The plastic pipe used in different fields, they have a common characteristic is the need to withstand the pressure and impact, and in turn, the position, and sometimes need to add metal inserts, the tube wall is generally thicker, so when the injection molding production, attention must be paid to the quality of plastic plastic the temperature, pressure, and (especially the two pressure holding time long) control, speed, special machine Chun's existing UPVC, SPVC, PP-R and PE special screw, machine fittings special emission maximum (National injection amount of 43 kg, a clamping force of 2000 tons), to ensure the plasticizing quality of different plastics, in the room (such as Liansu, Gu and other companies) in the process of using well. Below to PP-R pipe production, for example, to explain the specific characteristics of the process: (1) PP-R raw material properties: raw materials generally do not need drying.

- Q: Are plastic pipe fittings suitable for rainwater harvesting systems?

- Yes, plastic pipe fittings are suitable for rainwater harvesting systems. They are commonly used due to their durability, affordability, and resistance to corrosion. Additionally, plastic fittings are easy to install and maintain, making them a practical choice for collecting and distributing rainwater.

Send your message to us

Plastic Waste Pipes and Fittings PPR Reducers for Landscape Irrigation New Drainage System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords