Plastic Pipe Plumbing Fittings - PPR Pipe and Fittings Female Coupling and Equal Coupling from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Material: Plastic

Technics: injection

Place of Origin: China (Mainland)

Connection: Welding

Head Code: round

Color: white

Packaging & Delivery

Packaging Details: PE bag and carton

Delivery Detail: 30 Days

Working pressure(bar) | Temperature ℃ | Working year(H/Y) | |

Cold water | 0 to10 transient | To 25 | 8760 |

Hot water | 0 to10 transient | To 60 | 8710 |

To 80 | 50 |

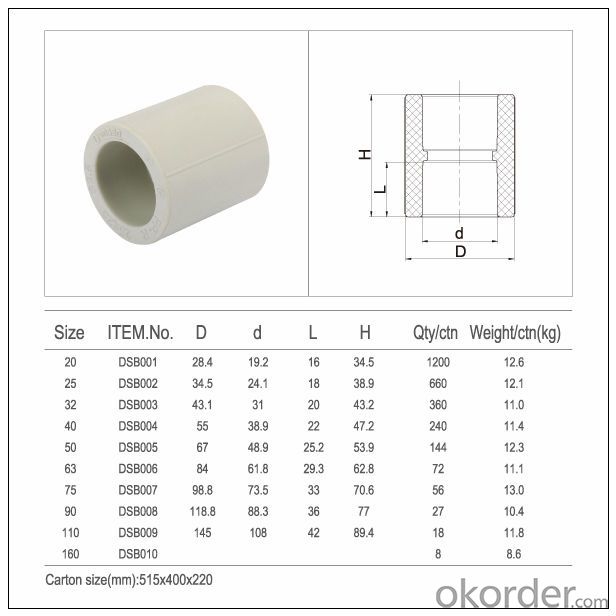

Specifications:

Standard: DIN8077/8078

Material: R200P from Korea

Size: DN20-63

Color: Green, White, Grey, Blue

Packaging & Delivery

Packaging Details: PE bag + carton

Delivery Detail: 15 Days

Main Product Features:

Large drum hub to maximize cable life

Self-activating automatic brake hold the load securely when crank handle is released

With cable or strap

Safety guard cover available

Top quality with competitive price

Widely used in the double beam bridge crane and gantry crane

Easy to install and high quality

Compact structure and reasonable design

Could be mounted on t he ground or wall!

Double drum!!

Advantages

1, High Temperature Resistance: the maximum sustained working temperature is up to 70 Degrees Celsius, the maximum transient temperature is up to 95 Degrees Celsius.

2, Heat insulation and Saving Energy: low thermal conductivity which is only 1/1500 of brass pipe, and 1/250 of steel pipe.

Non-toxic: no heavy metal additives would not be covered with dirty or contaminated by bacterium.

3, Corrosion Resistant: resist chemical matters or electron chemical corrosion.

4, Lower Installation Costs: light weight and good hot-melt performance can reduce installation costs by as much as 50% over metal piping system.

5, Higher Flow Capacity: smooth interior walls result in lower pressure loss and higher volume than metal pipes.

6, Long Life: more than 50 years under normal conditions.

7, Recycled and Environment-friendly.

FAQ

Q: What you offer?

A: Any kinds of goods you need, just send us the request, we will reply you back with the details very soon.

Q: Product quality and delivery time?

A: Normally 7-15 days after the order confirmed, we will collect the goods and inspect each of the items and send you the inspection photos for you to confirm.

Q: What's the regular shipping port?

A: Ningbo, Shanghai.

Q: What's your payment?

A: T/T or L/C at sight

- Q: What are the common installation mistakes to avoid with plastic pipe fittings?

- Some common installation mistakes to avoid with plastic pipe fittings include overtightening the fittings, not using the correct type of pipe for the specific application, not properly preparing the pipe ends before installation, and not using the appropriate solvent or adhesive for joining the fittings. It is also important to avoid using excessive force when connecting or disconnecting the fittings, as this can cause damage or leaks.

- Q: Can plastic pipe fittings be used for agricultural irrigation systems?

- Yes, plastic pipe fittings can be used for agricultural irrigation systems. Plastic fittings are commonly used in these systems due to their durability, corrosion resistance, and ease of installation. They are also cost-effective and can withstand the harsh conditions associated with agricultural irrigation, such as exposure to chemicals and varying weather conditions.

- Q: Can plastic pipe fittings be used for fuel transfer systems?

- No, plastic pipe fittings should not be used for fuel transfer systems. Plastic is not compatible with fuel and can degrade, leak, or cause a potential fire hazard. It is recommended to use fittings made from materials specifically designed for fuel transfer, such as metal or specialized fuel-resistant plastics.

- Q: Can plastic pipe fittings be used in wastewater systems?

- Yes, plastic pipe fittings can be used in wastewater systems. They are commonly used due to their durability, corrosion resistance, and cost-effectiveness. Plastic fittings, such as PVC or HDPE, are able to handle the demanding conditions of wastewater systems and are a popular choice for their ease of installation and maintenance.

- Q: Can plastic pipe fittings be used for radiant cooling systems?

- Yes, plastic pipe fittings can be used for radiant cooling systems. Plastic fittings are commonly used in these systems due to their durability, corrosion resistance, and ease of installation. Additionally, plastic fittings are compatible with the various types of plastic pipes commonly used in radiant cooling systems, such as PEX or CPVC.

- Q: Can plastic pipe fittings be used for central vacuum systems?

- Yes, plastic pipe fittings can be used for central vacuum systems. Plastic fittings are commonly used in central vacuum systems because they are lightweight, durable, and resistant to corrosion. They provide a cost-effective and reliable option for connecting the various components of the system, such as the vacuum unit, inlet valves, and tubing.

- Q: How do you connect plastic pipe fittings to steel pipes?

- To connect plastic pipe fittings to steel pipes, you can use a transition fitting. This fitting typically has a threaded end that can be screwed onto the steel pipe and a socket or glue joint that allows for the attachment of the plastic pipe. The transition fitting ensures a secure and leak-proof connection between the two different pipe materials.

- Q: What is the plastic pipe joint of water supply pipe?

- This depends on what kind of plastic you use, for example, you want PPR that connector is PPR pipe fittings

- Q: Can plastic pipe fittings be used in sewage treatment systems?

- Yes, plastic pipe fittings can be used in sewage treatment systems. Plastic pipes and fittings are commonly used in sewage treatment systems due to their durability, resistance to corrosion, and ease of installation. They are also cost-effective and can withstand the harsh conditions typically found in sewage treatment systems.

- Q: Can plastic pipe fittings be used for rainwater harvesting systems?

- Yes, plastic pipe fittings can be used for rainwater harvesting systems. Plastic fittings are commonly used in these systems due to their durability, corrosion resistance, and affordability. They are also compatible with various types of plastic pipes, making them a suitable choice for connecting and directing rainwater to storage tanks or other components of the rainwater harvesting system.

Send your message to us

Plastic Pipe Plumbing Fittings - PPR Pipe and Fittings Female Coupling and Equal Coupling from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords