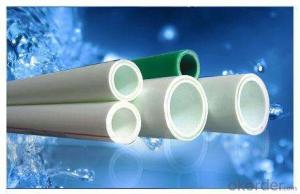

Plastic Pipe Tee Fittings PPR Ball Valve with Superior Quality Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Product

1. It is used in industrial fields, agriculture and garden irrigation

2. Beauty appearance.

3. Thermal insulation and energy saving.

4. Easy installation

5. Excellent heat resistance and pressure resistance

6. Affordable price

Size

Size | ITEM.No. | D | d | L | H | G | Qty/ctn | Weight/ctn(kg) |

20*1/2” | DSR021 | 28.5 | 19.2 | 16 | 70 | 1/2” | 108 | 26.64 |

25*3/4” | DSR022 | 34.3 | 24.1 | 17.5 | 76.5 | 3/4” | 72 | 24.12 |

32*1” | DSR023 | 42.6 | 31 | 19.5 | 88 | 1” | 42 | 23.87 |

Specification

Products name | Ball Valve |

Material | PPR |

Field of Application | Water |

Work temperature | -10℃-110℃ |

Packing | PE bag and carton |

Function | Kitchen, home, commercial, garden and general |

Place of origin | Hebei China(mainland) |

Brand | CMAX |

Certificate | CE,ISO9001 |

Product Applications:

1.Distribution for cool and hot water

2.Duct for drinkable water system

3.Pipes for kinds of high-temperature and low-temperature heating system

4.Pipes for heating and coolling settings in solar energy system

5.Connecting pipe for air conditioners

Product Advantages:

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving.

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden installation

9) Recyclable, environment-friendly, accords with GBM standards

Main Product Features:

1. Large drum hub to maximize cable life

2. Self-activating automatic brake hold the load securely when crank handle is released

3. With cable or strap

4. Safety guard cover available

5. Top quality with competitive price

6. Widely used in the double beam bridge crane and gantry crane

7. Easy to install and high quality

8. Compact structure and reasonable design

9. Could be mounted on t he ground or wall!

10. Double drum!!

Company Profile

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development.

FAQ:

Q1:How Can I Get A Sample?

A1:You can get samples by communicate with our export sales.

Q2:How Long Is Delivery?

A2:Delivery time will be30-45days according to order quantity.

Q3:What Is The MOQ?

A3:MOQ depends on different items.

Q4:What Is Our Normal Payments Terms?

A4:Our normal payment terms now is: T/T, L/C or western union,paypal

- Q: How about plastic pipe fittings?

- The length or depth of the connecting part of the pipe (called the socket in the standard) is long enough. Irregular production of pipe fittings, in order to reduce costs, deliberately Jerry built, socket is generally shorter, so that in the future use of the joint leakage easily. If from the angle of safe use, the longer the socket depth, the more users can compare or actual measurement. From an economic point of view, however, the minimum socket depth is given in the standard. 5., pay attention to the purchase of pipe fittings and pipe matching issues. First try several times into the pipe inserted tube, should not feel difficult, but after inserted into not too loose for good.

- Q: Are plastic pipe fittings suitable for pneumatic conveying systems?

- Yes, plastic pipe fittings are suitable for pneumatic conveying systems. They offer several advantages such as corrosion resistance, lightweight construction, ease of installation, and flexibility. Additionally, plastic fittings can handle the high pressures and abrasive materials commonly found in pneumatic conveying systems.

- Q: Can plastic pipe fittings be used for irrigation filtration systems?

- Yes, plastic pipe fittings can be used for irrigation filtration systems. Plastic pipe fittings are commonly used in irrigation systems due to their durability, corrosion resistance, and affordability. They can easily be connected to various types of pipes and are compatible with different filtration components, making them suitable for the construction of irrigation filtration systems.

- Q: Do plastic pipe fittings have a maximum operating temperature?

- Yes, plastic pipe fittings do have a maximum operating temperature. The maximum temperature may vary depending on the type of plastic used in the fitting. It is important to refer to the manufacturer's specifications to ensure that the fittings are used within the recommended temperature range to prevent potential damage or failure.

- Q: Are the elbow and three - pipe fittings installed in the water supply and drainage pipes included?

- Indoor heating plastic pipe, aluminum-plastic composite pipe, stainless steel pipe, copper pipe installation project, the pipeline joint parts as materials, according to design drawings to determine the number and loss of 1% of the cost of materials shall be calculated separately.

- Q: Can plastic pipe fittings be used for water desalination systems?

- Yes, plastic pipe fittings can be used for water desalination systems. Plastic fittings are commonly used in water treatment systems due to their corrosion resistance, durability, and affordability. They effectively connect and direct the flow of water in desalination systems, ensuring reliable and efficient operation.

- Q: Are plastic pipe fittings suitable for hydroponic systems?

- Yes, plastic pipe fittings are suitable for hydroponic systems. They are commonly used due to their durability, affordability, and resistance to corrosion. Plastic fittings can effectively handle the water and nutrient solution used in hydroponics without any adverse effects on the plants or the system.

- Q: How are plastic pipe fittings different from metal pipe fittings?

- Plastic pipe fittings are different from metal pipe fittings in various ways. Firstly, the material used in their construction is different, with plastic fittings made from various types of polymers, while metal fittings are typically made from materials like brass, copper, or steel. This difference in material affects their durability, as metal fittings tend to be more resistant to wear and tear compared to plastic fittings. Additionally, metal fittings generally have higher pressure and temperature ratings than plastic fittings, making them suitable for more demanding applications. However, plastic fittings are often more affordable and easier to install due to their lighter weight and flexibility. Ultimately, the choice between plastic and metal fittings depends on the specific needs of the plumbing system and the desired level of durability and performance.

- Q: How do plastic pipe fittings handle extreme weather conditions?

- Plastic pipe fittings are generally designed to handle a wide range of weather conditions, including extreme temperatures and harsh weather elements. Most plastic materials used in these fittings, such as PVC or CPVC, have good resistance to UV radiation, humidity, and temperature variations. They are engineered to withstand freezing temperatures without cracking or becoming brittle, as well as resist corrosion from moisture or chemicals. However, it is important to note that the specific performance of plastic pipe fittings can vary depending on the type and quality of the material used, as well as the manufacturer's specifications.

- Q: Are plastic pipe fittings resistant to erosion and abrasion?

- Yes, plastic pipe fittings are generally resistant to erosion and abrasion.

Send your message to us

Plastic Pipe Tee Fittings PPR Ball Valve with Superior Quality Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches