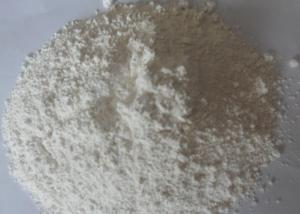

Powder Binder for Chopped Strand Mat CWB-966

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 11200 Kgs kg

- Supply Capability:

- 100000 Kgs kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Powder Binder for Chopped Strand Mat CWB-966

CWB-918/966 is binder for fiberglass chopped strand mat and composed of bisphenol A unsaturated polyester resin (nonionic).

CWB-918/966 imparts to mat good handle and moldability.

Usually CWB-918/966 is applied directly by spattering the powder through hopper on the traversing chopped strand layer.

Binder content in chopped strand mat is around 2-4%.

Features of Powder Binder for Chopped Strand Mat CWB-966

CWB-918/966 provides soft and flexible properties to the mat with sufficient strength.

CWB-918/966 is excellent in penetrating effect for the process resins, provides transparency to the finished product and excels in boiling water resistance.

In the course of spattering process at the factory, CWB-918/966 easily slips down through the hopper on the traversing chopped strand layer below because of its antistatic and free flow features.

CWB-918/966 can be easily dispersed in water.

Storage of Powder Binder for Chopped Strand Mat CWB-966

CWB-918/966 should be stored out of sun below 30℃.

Package of Powder Binder for Chopped Strand Mat CWB-966

The binder is to be packed in a plastic bag, then to be put in the carton drum.

Net weight is 140Kg per drum.

The quantity for a 20’ container is 11200KGS.

- Q: When you nail the adhesive and adhesive first

- The bottom glue is isolated, if a surface cut, you worry about color seeping into the nail surface resulting in nail discoloration, only need to use a primer, primer to light, is really between armour and colors with a transparent insulating layer.

- Q: Which toothpaste does not contain gum glue? Where can I buy it?!

- Cassava powder: tapioca powder is widely used in food industry and non food industry with two kinds of raw starch and various modified starch. Modified starch can be customized according to the specific requirements made by users for special purposes. 1 cassava starch can be used as food raw material. Tapioca starch is widely used in food formulations, such as baked products, and also used for making extruded small food and tapioca beads. Modified starch or starch derivatives have been used as thickeners, adhesives, extenders and stabilizers, as well as the best additives, sweeteners, flavoring agents, and fat substitutes. Thailand cassava starch food including canned food, frozen food, dry mixed food, baked foods, food, seasoning, soup, sausage, dairy products, meat and fish products and baby food. 2 tapioca powder can be used as a stabilizer in beverages. Modified starch is used as a stabilizer in solids containing beverages. In beverages, cassava starch sweeteners are better than sucrose because the former improves the processing process and reinforces the product characteristics, and is combined with other sweeteners to fully meet consumer demand. The high hydrolysis sugar syrup obtained from the hydrolysis of cassava starch is an ideal source of fermentable sugars in beer brewing. 3 cassava flour can do candy in raw cassava starch and modified starch has many uses in the production of candy, such as gelling, thickening, stable system, enhanced control foaming, crystallization, bonding, film forming, add luster etc..

- Q: Why can sodium silicate be used as adhesive?Bonding principle?

- Principles of inorganic adhesivesThe chemical bond theory that the adhesive between the adhesive and adherend molecule interactions, and sometimes chemical bonds, such as rubber and metal copper bonding interface and coupling agent on the bonding effect of isocyanate, metal and rubber adhesive interface research showed that chemical bond formation. The strength of chemical bonds is much higher than that of van Dehua; the formation of chemical bonds can not only increase the adhesion strength, but also overcome the disadvantage of adhesion damage due to desorption. However, the formation of chemical bonds is not common, and the formation of chemical bonds must satisfy certain quantized parts. Therefore, it is impossible to make the chemical bond between the adhesive and the adhered material. Moreover, the number of chemical bonds at the unit adhesion interface is much smaller than the number of intermolecular interactions, so the adhesion force from the intermolecular forces cannot be neglected.

- Q: Adhesives for sanitary porcelain

- Method for using ceramic tile adhesive:1, there is a high quality ceramic tile adhesive cement, quartz sand, fiber and other materials through scientific proportioning, and water use ratio is very important, usually by the ratio of 1:0.25-0.3 on the line, the water is not too much.2, the ceramic tile adhesive into the water, stir into paste, and then placed at rest for about 10 minutes, then stir, so that it can increase the adhesion strength.3, will float tile adhesive coating in most parts of the tile surface, the dust must be cleared before the surface of ceramic tile.4, finally compaction tiles on the line.

- Q: There are formaldehyde free wood adhesive?

- Environmental protection wood adhesive -WQ823 (non formaldehyde water soluble isocyanate adhesive)Non formaldehyde adhesive, non formaldehyde, benzene, non-toxic, solve the pollution problems of formaldehyde, really in line with Japan Fc0 and European E0 standard, with the production of wood-based products adhesive has been approved by the Japanese JAS standard peel test.

- Q: What adhesives do you use to make small particles of food stick together?

- White sugar, food grade carrageenan, agar. Soaked with boiling water will spread out, but after cooling will coagulate together. Carrageenan is difficult to bubble open.

- Q: Adhesive for sticking iron

- If the requirements of quick drying with QIS-3008 special metal adhesive; if the two-component QIS-5011 epoxy AB glue, automatic mixing packaging, glue glue gun directly out of it. I hope I can help you!

- Q: What are the categories of adhesives?

- Synthetic adhesive can be divided into synthetic thermosetting resin adhesive, synthetic thermosetting resin adhesive and thermosetting elastomer adhesiveThese four types are synthetic adhesive and compound adhesive.

- Q: What is the difference between inorganic adhesive and natural adhesive?

- Inorganic adhesive: a general organic adhesive that can withstand high temperatures, usually below 100 degrees celsius. Such as latex at 60 degrees below, epoxy resin at about 100, phenolic resin at about 220 degrees celsius. The inorganic adhesive can withstand the high temperature of 600 - 900 degrees Celsius, and improve the composition after more than 1800 degrees celsius.

- Q: Don't know how tachco tile adhesive, introduced under the assistance.

- Is directly pasted on the tile tile kind, very convenient, is also very popular, especially TTB ceramic tile adhesive is an old brand, and even a brick tile!

1. Manufacturer Overview

| Location | Nantong, China |

| Year Established | 2005 |

| Annual Output Value | Above US$ 9 Million |

| Main Markets | overseas companies in Thailand, Vietnam, South Korea, India, Singapore, France and many other countries and regions. |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 10-20% |

| No.of Employees in Trade Department | 3-5 |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | Above6,000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | |

| Product Price Range | Average |

Send your message to us

Powder Binder for Chopped Strand Mat CWB-966

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 11200 Kgs kg

- Supply Capability:

- 100000 Kgs kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches