Polyethylene filling masterbatch for PE PP PS ABS

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyethylene filling masterbatch is a kind of micron-sized Calcium Carbonate masterbatch pure withraw material PE,PP or styrene resin as the carrier.

Customers decide the amount according to theneeds,it has the good physical propertities, the dispersity, stability and does not affect the processing precision of machine screw.

Such masterbatch can be widely used in PE.PP.PS.ABS .

All kinds of plastic products,such as PE plastic bags,plastic injection.

Application: Woven bags,flexible freight bags

Package: packed by woven bags,25kg per bag,store in a dry place.

Advantage of Masterbatch:

1.This series color masterbatches are of high concentration pigment with bright colors.

2.When they are used in resins, it shows better dispersing and stablility performance.

3.Also the mixture has the highest mechanical intensity preservation rate.

4.A broad standard color range available from stock as well as tailor made products develop according to customer requirements.

Features of Masterbatch:

-Standard, universal, or custom colors

-Carriers optimized for easy processing

-Production orders shipped in 5 days

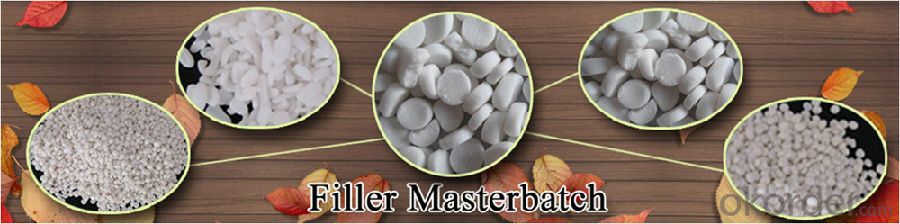

Product Pictures

- Q: Pollution in the production of plastic raw materials from petroleum production

- Manufacturing process of resin is the number of small molecular materials (high molecular compound monomer, alkane, olefin, could also have liquid such as gasoline and diesel decomposed) by polymerization together into a polymer compound. The polymerization can be divided into polymerization and polycondensation according to the composition of monomer and the change of result.The reaction of monomer addition and polymerization is called polymerization. Condensation polymerization is the process of reaction, in addition to forming high polymer, but also produce water, alcohol, ammonia and other low molecular by-products. The composition of the polymer is different from that of the raw monomer. After polymerization, the polymers with large molecular weight can be obtained. Synthetic resins are polymers of high molecular weight. Resins can be divided into two categories according to their properties after heating: one is called thermoplastic resin, and the other is thermosetting resin. Thermoplastic resin after heating can soften, flow, repeatedly plasticization and molding, such as polyethylene, polypropylene, polystyrene, polyvinyl chloride, polyamide; thermosetting resin is soluble and fusible before processing, but in the heating, pressurizing and curing agent under the action can become insoluble and infusible, cannot be heated again softening products to curing, phenolic resin, urea formaldehyde resin, epoxy resin, unsaturated resin belongs to this kind of resin.

- Q: Plastic PPT30S add what material will increase hardness?

- Technical parameters of Qilu Petrochemical PP (T30S)Project quality index test method of isotactic index% greater than 95 GB/T 2412 powder ash%, less than 0.03 GB/T 9345 tensile yield strength greater than 28 GB/T, MPa 1040 kg/m3 0.9~0.91 density, cleanness, color particle, /kg melt flow rate of 11~20, g/10min 2~4 GB/T 3682 brand name: Qilu

- Q: How many types of plastics are there?

- Name: ABS engineering plastics, can be used for connecting piece, seat back, seat board, it is able to perform plastic electroplating (water plating) the main raw material.

- Q: What is the hardness of PAEK+30%GF plastic material?

- The German mineralogist 7 (F.Mohs) from nature ten minerals commonly used as the standard, the hardness is divided into 1 degrees to 10 degrees ten grades, namely Moss hardness standard (Mohs Hardness), also known as the Moss hardness (Mohs hardness).Mohs hardness used to express the performance characterization of mineral mutual abrasion resistant ability.

- Q: What are the raw materials for making plastics?

- 1. the main component of plastic raw material is resin2: plastic raw material is made of polymer synthetic resin (polymer) as the main ingredients penetrate various auxiliary materials or additives, in particular temperature, has the plasticity and fluidity under pressure, can be molded into shape and maintain the same shape of material under certain conditions.

- Q: How is plastic material made out?

- The main components of plastic resin (in the early stage of coal tar products and calcium carbide carbide, it is used for oil and natural gas products, such as ethylene, propylene, benzene, formaldehyde and urea).

- Q: What is the disposable transparent plastic cup?

- GPPS is generally done, do once thrown away, GPPS advantage is cheap, good transparencyPP material is good food grade, non-toxic, but transparent less than GPPS degree, PP toughness better than GPPS, GPPS crisp

- Q: What is the plastic bag made of?

- The main raw material of plastics is oil and natural gas, that is, carbon hydrogen compounds. First, the appropriate macromolecular components in petroleum and natural gas are extracted, first split into monomers, and then polymerized into polymers to become plastic

- Q: What kind of plastic material is used for medical instruments?

- According to the use requirements of medical plastics, it is often necessary to make products with surface hydrophilicity, anti coagulation, radiation sterilization and other special functions.

- Q: What is the raw material for producing corn starch plastic film?

- Starch and biodegradable plastics mixing of biomass materials currently used most commonly used aliphatic polyester or aliphatic polyester mixed starch manufacturing, aliphatic polyester mainly includes the use of renewable resources as raw materials for the production of poly lactic acid, by microbial synthesis of polyhydroxyalkanoates (PHB, PHA), as well as for petroleum polycaprolactone synthesis the raw materials (PCL), polybutylene succinate (PBS) and its copolymer. Using starch and biodegradable polymer material mixing technology can produce a completely biodegradable plastic film and packaging materials, close to the performance of plastic, and theoretically solve the biodegradable polymer material with the characteristics of molecular design, molecular tailoring and chemical modification of starch, physical and chemical modification, can obtain good performance and low cost and control the degradation period can be completely biodegradable materials.

Send your message to us

Polyethylene filling masterbatch for PE PP PS ABS

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches