Polyester Insect Pleated Screen Mesh in Small MOQ

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyester Insect Pleated Screen Mesh in Small MOQ

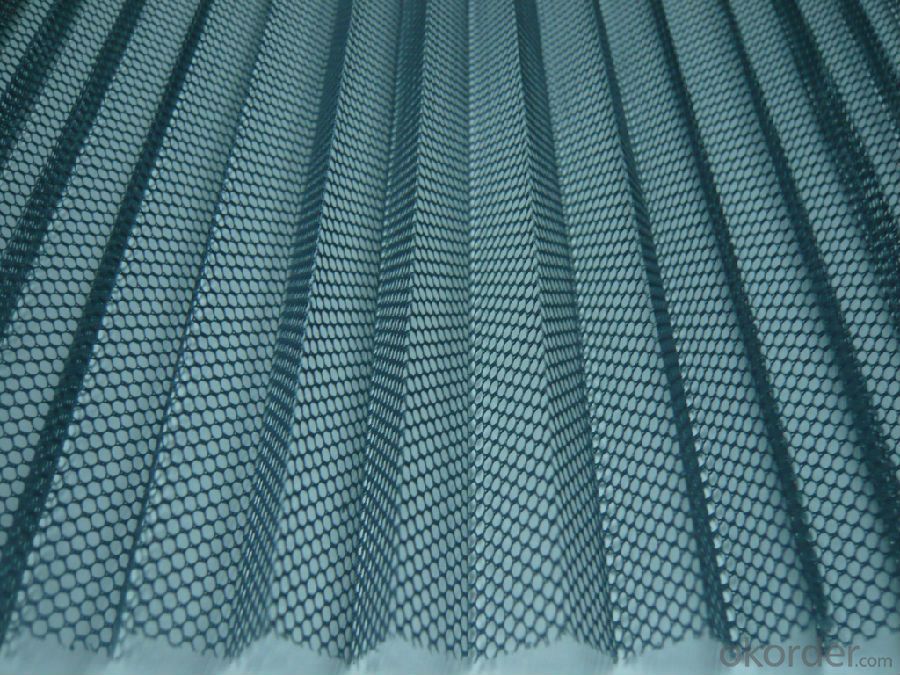

Description of Pleated Insect Screen mesh

Black Pleated Insect Screen mesh is a kind of pleated mesh with economical and practical. It made by polyester yarn, best suitable for the pleated/plisse screen window and door system. It is widely used for air exchange and insects proof in high-grade office building, residence and various buildings. It is also used for field, garden, vegetable shed, ect.

Advantage of Pleated Insect Screen mesh

▪ Best protective product to keep out a wide range of pests and insects

▪ Anti-UV, Anti-Static, Water proof, Durable

▪ Easy to clean, and easy to operation.

Specification of Pleated Insect Screen mesh

PRODUCT | Pleated Insect Screen mesh | |

WOVEN STRUCTURE | PLEATED | |

COLOR | GRAY, BLACK, | |

YARN DIAMETER (MM) | WARP | 0.3±0.02MM |

WEFT | 0.3±0.02MM | |

ENDS DENSITY (ENDS/INCH) | WARP | 18 |

WEFT | 16 | |

AREA WEIGHT (G/M2) | 75±5G/M2 | |

COMPOSITION | POLYESTER | |

BREAKING STRENGTH (N/25MM) | WARP | >180 |

WEFT | >160 | |

STANDARD WIDTH(M) | FROM 0.6M TO 2.7M | |

STANDARD PIECE LENGTH(M) | 30M | |

PIECES LENGTH (PC) | AVAILABLE UPON REQUEST | |

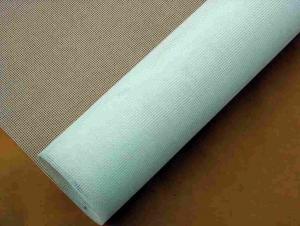

Images of pleated insect screen

Package of Black Pleated Insect Screen mesh

FAQ:

1. What's the quality?

Very fine, we have been exported to more than 30 countries.

2. How long get reply?

Usually within 24 hours.

3. What's the MOQ?

2000 square meters.

- Q: The crimped wire mesh weaving method

- Stainless steel wire, steel wire, galvanized wire, black iron wire, steel wire, copper wire, white Huang Tongsi and other non-ferrous metal wire.

- Q: For example: 24 mesh size is 0.79mm, wire diameter of 0.27mm, because of the special requirements, whether can processing wire diameter is 0.4mm, is 0.79mm aperture screen? Such online.

- But you behind the requirements of wire diameter 0.4mm 0.79mm aperture is not 24, but 25.4/ (0.4+0.79) = 21.3. This is the theoretical value. The actual production environment is not up to the number of

- Q: Line of nylon line of nylon yarn of strong horse line is good?

- One thing that can't be replaced is that it has a different place from the fluorocarbon line, because it can be in agreement with the gravity of the water, so when you search it, it is completely parallel to the surface of the water. If you are fishing water, need to line is parallel to the water surface. In order to produce smooth posture, with the proportion of fluorocarbon water is about 1:1.7 or so, obviously sinking faster, so in the operation of water, basically a lot of attitude will be lost.

- Q: Braid, plain weave and twill weave, what is the difference in the use of functions?For example: from the aspects of the force, the twill than plain stress or strength, etc.The woven net price, mainly uses in favor of filtering or protection, and twill is not?Please answer the detailed points, thank you!

- Stainless steel mesh, the name is a general name, in general, all stainless steel wire mesh can be said as a stainless steel mesh.

- Q: Why the metal box door and the metal box must be made of braided copper wire

- Product use scopePower station, generator, transformer, power transmission and distribution, switch cabinet, bus bar, industrial electric furnace, electrolytic smelting, welding equipment, rectifier equipment and other flexible connection of the majority of passengers.

- Q: Mainly used in what place?

- If in the circuit, can play the electromagnetic shielding, increase the ability to resist interference.

- Q: Can be found is now the feeling is hard metal, I want to find a weaving, like a basketball net like the wood there?

- You should have sold to buy the basket shop.

- Q: I have a pair of white jogging shoes, the upper is made of nylon mesh woven fabric, has been dirty, and washed with a brush, the surface is not very good, how to wash, do not destroy the net face ah?

- Clean with a soft brush or sponge

- Q: How many square meters can be made of a ton of wire

- This is a very deep questionAbout more than 1 thousand square meters

- Q: The aluminum foil shielding layer can be designed into a smooth, concave and convex structure, which is used to replace the composite shielding of the aluminum foil + metal braid

- No, the role of metal woven mesh is to spread out the static electricity

Send your message to us

Polyester Insect Pleated Screen Mesh in Small MOQ

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords