Plastic Poly Pipe Fittings for PPR Pipe Landscape Irrigation Drainage Application New 2024

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction Of Products:

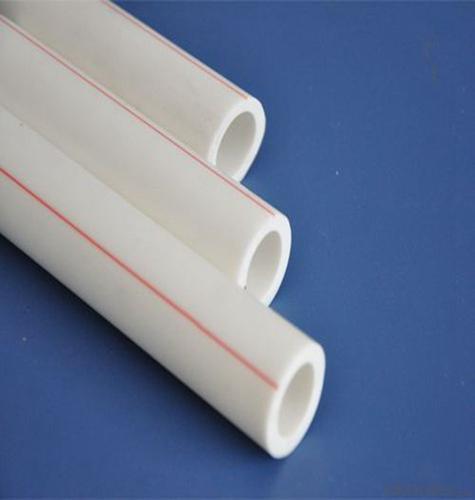

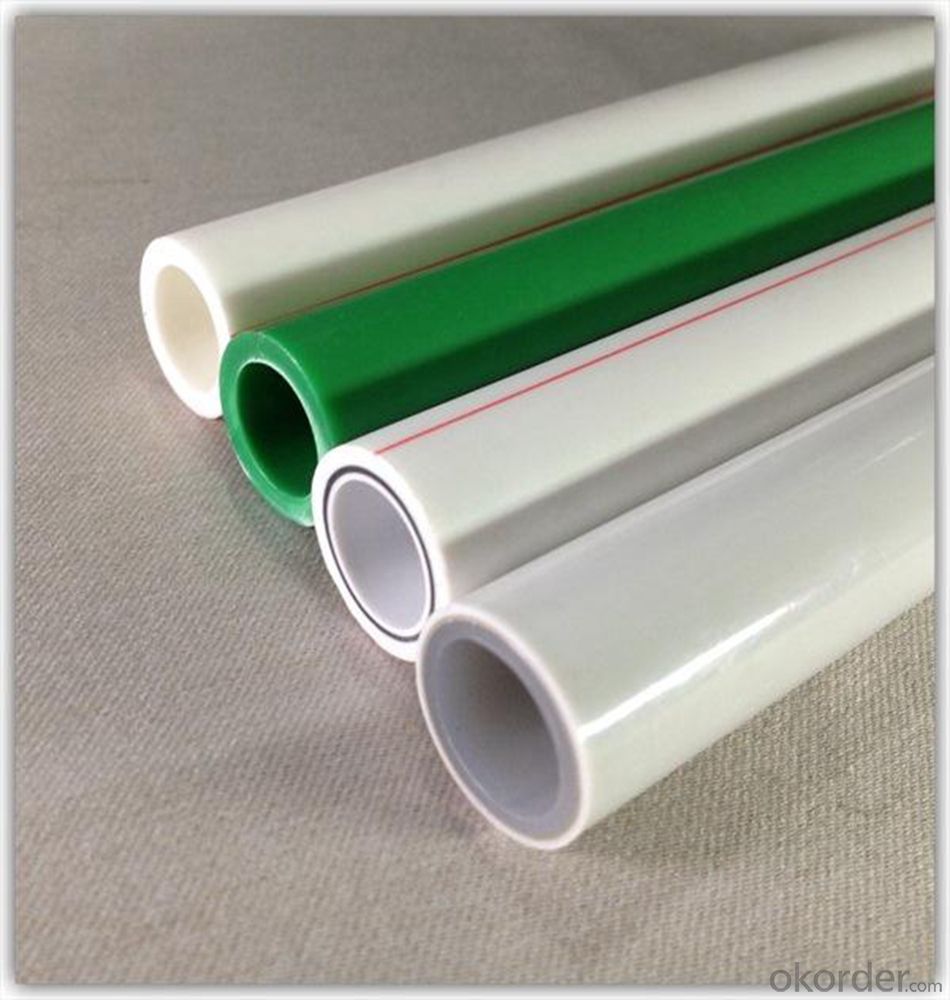

Material: PP-R, PPR

Technics: injection

Type: pipe

Place of Origin: China (Mainland)

Model Number: 20-110MM

Connection: Welding

Shape: Equal

Head Code: round

Product Type: Ppr pipe

Color: white, grey, green

Item number: DSE001-DSE010

PPR Pipe And Fitting Size:

1.25MPa | 1.6MPa | 2.0MPa | 2.5MPa | |

Outer | Wall | Wall | Wall | Wall |

Diameter | Thickness | Thickness | Thickness | Thickness |

dn(mm) | en (mm) | en (mm) | en (mm) | en (mm) |

20 | 2.0 | 2.3 | 2.8 | 3.4 |

25 | 2.3 | 2.8 | 3.5 | 4.2 |

32 | 2.9 | 3.6 | 4.4 | 5.4 |

40 | 3.7 | 4.5 | 5.5 | 6.7 |

50 | 4.6 | 5.6 | 6.9 | 8.3 |

63 | 5.8 | 7.1 | 8.6 | 10.5 |

75 | 6.8 | 8.4 | 10.1 | 12.5 |

90 | 8.2 | 10.1 | 12.3 | 15.0 |

110 | 10 | 12.3 | 15.1 | 18.3 |

160 | 14.6 | 17.9 | 21.9 | 26.6 |

Products Show:

Specification:

Standard: DIN8077/8078

Material: R200P from Korea

Size: DN20-63

Color: Green, White, Grey, Blue

Packaging & Delivery

Packaging Details: PE bag + carton

Delivery Detail: 15 Days

Our Advantages:

1.It is used in industrial fields, agriculture and garden irrigation

2. Beauty appearance.

3.Thermal insulation and energy saving.

4. Easy installation

5.excellent heat resistance and pressure resistance

6. affordable price

FAQ:

Q1: How Can I Get a Sample?

A1: You can get samples by communicate with our export sales.

Q2: How Long Is Delivery?

A2: Delivery time will be30-45days according to order quantity.

Q3: What Is The MOQ?

A3: MOQ depends on different items.

Q4: What Is Our Normal Payments Terms?

A4: Our normal payment terms now is: T/T, L/C or D/P D/A.

- Q: What tools and methods are needed for the installation of plastic hoses and steel tubes?

- In some high-rise buildings, designers often need to enlarge the diameter of the pipe when they are designed, and the construction is usually done at the bottom of the riser with two pipes with the same pipe diameter as 45. Elbow connection, and then in the discharge pipe for variable diameter, often easy to change in the connection at the formation of gas plug, resulting in pipe blockage, affecting the drainage of the pipe. The correct method is to use the reducer at the bottom of the riser to enlarge and connect the elbow, and the eccentric reducer is used for the eccentric diameter, and the eccentric side is on the inner circle side of the turn.

- Q: Plastic pipe fittings and plastic doors and windows on the stain in what way?

- They are good at this, generally do not clean up their own.

- Q: How do plastic pipe fittings handle thermal expansion and contraction?

- Plastic pipe fittings are designed to handle thermal expansion and contraction through their flexibility and ability to withstand temperature changes. The materials used in plastic pipe fittings have a low coefficient of thermal expansion, meaning they expand and contract less compared to other materials like metal. This allows the fittings to accommodate the expansion and contraction of the pipes without causing damage or leaks. Additionally, plastic pipe fittings often include expansion joints or coupling systems that provide further flexibility and allow for movement without compromising the integrity of the system.

- Q: Can plastic pipe fittings be used for cooling systems in data centers?

- Yes, plastic pipe fittings can be used for cooling systems in data centers. Plastic fittings are commonly used in various plumbing applications, including cooling systems. They offer advantages such as corrosion resistance, ease of installation, and cost-effectiveness. However, it's important to ensure that the plastic fittings chosen are suitable for the specific requirements and conditions of the cooling system in question.

- Q: Can plastic pipe fittings be used in water well systems?

- Yes, plastic pipe fittings can be used in water well systems. Plastic fittings are commonly used in water well systems due to their durability, corrosion resistance, and affordability. They provide a reliable and long-lasting solution for connecting different components of the water well system.

- Q: Can plastic pipe fittings be used for drinking water systems?

- Yes, plastic pipe fittings can be used for drinking water systems. However, it is important to ensure that the fittings are made from materials approved for potable water applications and meet the necessary standards and regulations to ensure the safety of the drinking water.

- Q: Can plastic pipe fittings be used for chemical injection skids?

- Yes, plastic pipe fittings can be used for chemical injection skids. Plastic pipe fittings are often preferred for chemical injection skids due to their corrosion resistance, durability, and cost-effectiveness. However, it is important to consider the compatibility of the plastic material with the specific chemicals being injected to ensure proper functioning and safety.

- Q: Can plastic pipe fittings be used for industrial applications?

- Yes, plastic pipe fittings can be used for industrial applications. Plastic pipe fittings are durable, lightweight, and resistant to corrosion, making them suitable for various industrial settings. They are commonly used in industries such as chemical processing, water treatment, and HVAC systems. Additionally, plastic pipe fittings can offer cost savings compared to traditional metal fittings, making them a popular choice in many industrial applications.

- Q: How are plastic pipe fittings manufactured?

- Plastic pipe fittings are typically manufactured through injection molding. This process involves melting plastic resin pellets and injecting the molten material into a mold cavity. Once the plastic cools and solidifies, the mold is opened, and the finished pipe fitting is ejected. Injection molding allows for the mass production of plastic pipe fittings with consistent dimensions and high precision.

- Q: Are plastic pipe fittings resistant to soil movement and settlement?

- Yes, plastic pipe fittings are generally resistant to soil movement and settlement. They are designed to be flexible and can withstand minor shifts in the soil without breaking or leaking. However, in areas with significant soil movement or settlement, additional measures such as proper installation, support, and reinforcement may be necessary to ensure the stability and longevity of the fittings.

Send your message to us

Plastic Poly Pipe Fittings for PPR Pipe Landscape Irrigation Drainage Application New 2024

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords