PE gas pipe manufacture Y310

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. PE gas pipe manufacture (GB/T 15558-2003)

Quick Details

· Place of Origin: China (Mainland)

· Material: PE

· Specification: 20-630mm

· Length: 5.9/11.8M

· Standard: GB/T15558-2003

Packaging & Delivery

Packaging Details: | bundle or as your required |

Delivery Detail: | within 15 days after downpayment |

Specifications

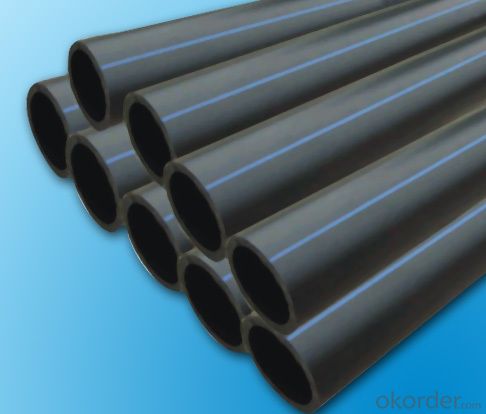

PE gas pipe manufacture (GB/T 15558-2003)

1. OD:20-630mm

2. Standard: GB/T15558-2003

3. Quality with competitive price

PE GAS PIPE

Material: PE 100

Specification: 20mm-630mm

Length: 5.8m 11.8m per length

Thickness: 2.3mm~57.3mm

Standard: GB/15558, ISO4437

Color: black, yellow or black with yellow stripe or others

Feature:

**Long service life: PE pipe can be used safety for more than 50 years

**Excellent resistance to corrosion capability: It can endure the erosion of various kinds of chemical media, no electrochemical corrosion.

**Excellent transportation capability: the inner side of the PE pipe is smooth and has litter abrasion and resistance. The absolute roughness k=1.01mm and “k” will not change with time.

**Reliable joint capability: the intensity of the welded joint of PE pipes is above the pipe itself. The interface will not disconnect because of the moving of soil or the live load.

**Reliable safety capability: PE pipe has strong capability of anti-cracking and is not prone to crack.

**Better resistance to concussion capability: PE pipe possesses high toughness and can endure strong impact. Pressure of heavy things will not cause the pipe to break.

**Strong toughness: PE pipe is a kind of pipe that possesses high toughness whose breaking elongation rate generally exceeds 500% and has strong ability to adapt to the uneven settlement of the pipe bending.

**Excellent flexibility: PE pipe can be easy to change in accordance with the construction requirements. Small-diameter pipe is available to be supplied in coils.

**Installation cost lower: light weight, easy handling and installing, simple welding technique and exemption of being embalmed result in low construction cost.

Application:

gas distribution, environmental protection, and chemical industry etc.

2. PE PIPE MANUFACTURE (ISO 4427)

Quick Details

· Type: Other Plastic Building Materials

· Place of Origin: China (Mainland)

· Size: 16-1600mm

· Color: Black, blue

Packaging & Delivery

Packaging Details: | plastic bags or as your request |

Delivery Detail: | Within 25 days after receiving the payment |

Specifications

PE PIPE MANUFACTURE (ISO 4427)

A. Material: High quality PE80 or PE100

B. Diameter: 16 to 1600mm

C. Pressure:0.6-1.6Mpa

PE PIPE MANUFACTURE (ISO 4427)

Features:

**Sizes: 16 to 1600mm

**Pressure Rating: 0.6MPa, 0.8MPa, 1.0MPa, 1.25MPa, 1.6MPa

**Colors: blue, black or other colors on request

**Connection: socket fusion joint, butt fusion joint, electro fusion joint, flanged joint

**Standard: GB/T 13663, ISO 4427

**Certification: ISO9001, ISO14001

**Packaging: coils in plastic bag or as your request

Advantages:

**Non-toxic: no heavy metal additives, would not be covered with dirt or contaminated by bacterium

**Corrosion Resistant: resist chemical matters or electron chemical corrosion

**Lower Installation Costs: light weight and ease of installation can reduce installation costs by

as much as 50% over metal piping system

**Higher Flow Capacity: smooth interior walls result in lower pressure loss and higher volume

than metal pipe

**Longevity: more than 50 years under proper use

**Recycled and Environment-friendly

Application

water pipe network system, industrial liquids transportation, Agricultural irrigation pipe and sewage treatment

- Q: How can I connect the gas tank connection hose?

- The general is directly inserted into the connector on the line, if loose, can use wire twist, still feel not reliable, can go to the market to buy two hoop, screw on the line.Keep it clean.

- Q: Could you tell me the maximum pressure that the hose can bear?

- The working pressure of general industrial hydraulic high pressure hose is about 35MP, and the bursting pressure can reach 60mp.

- Q: The small hose attached to the grease gun is coarse or fine at the joint

- The joint on the grease gun is made of fine thread. The characteristics of fine thread are small pitch, small spiral angle, good self-locking, and not easy to loosen.

- Q: Natural gas can be connected to a gas cooker. Can rubber tube be used?

- The user may use gas professional hose or corrugated steel pipe to connect, but the service life of the hose is 12--18 months,Commercial and construction households can and must be connected by qualified professionals

- Q: How to remove hose odor?

- When rubber is peculiar, it can be scrubbed by hydrogen peroxide. After drying, the odor will disappear. Or with waste tea sent to rubber products, tea has the role of adsorption odor.

- Q: How to remove the smell of gasoline in the car?

- After assembling and disassembling the gasoline pump the work of assembling and disassembling the gasoline pump needs to be finished in the car, and some omissions are unavoidable in the process.Answer: after the disassembly of gasoline pumps, check whether there is no problem, and if there is a problem on the road, please go back to the repair shop to check the installation defects of the gasoline pump.

- Q: Is the metal hose the same as the soft connection?

- Some places are a term, but there are also soft connections, non-metallic soft connections, metal soft connections, so it's better to ask what you want

- Q: Excuse me: how can a pen with a rubber tube attract more ink?

- First suck some of the hose, and then put the pen flat in the ink. It's OK inside

- Q: How long is the service life of a rubber tube?

- Look at what, the water does not move, you can use 5-10 years, activities may not! Generally 3-5 years resistant to oil!! See how it works!!

- Q: Excuse me, how can I get waterproof wires in the water?

- The wire connector that enters the water can be "waterproof" and "waterproof"Waterproof joints, as the name suggests, can be applied to the water environment, providing safe and reliable connector joints. For example: LED street lights, lighthouses, cruise ships, industrial equipment, sprinkler and so on, all need to use waterproof joints.

Send your message to us

PE gas pipe manufacture Y310

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords