On Line Monitoring System for High Temperature Gas at Kiln Tail

- Supplier:

Hefei GoodTimes Automation Co.,Ltd.

Hefei GoodTimes Automation Co.,Ltd.

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

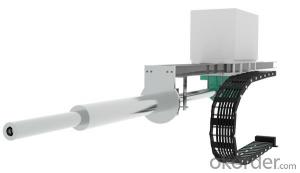

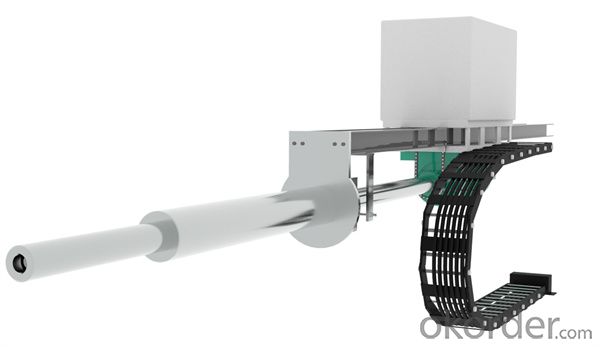

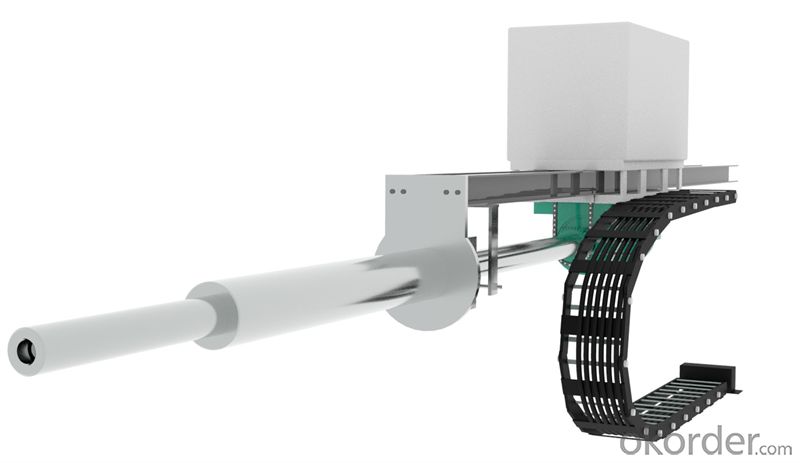

On line monitoring system for high temperature gas at kiln tail is specially designed for the pain point of the traditional analyzer sampling device. The system is mainly used to monitor the gas components in the smoke chamber at the end of the kiln in the dry cement production line.The system is mainly composed of sampling pretreatment system, circulating cooling system, electrical control system and gas analysis system.The sampling pretreatment system adopts automatic blockage removal, circulating cooling, rotating material shaking, three-stage back blowing and multistage purification to realize the stability and continuity of high temperature and high dust flue gas extraction.The gas analysis system adopts non-dispersed infrared technology to monitor NOX, CO, O2 and other gas concentrations in flue gas in real time.Kiln operators can reasonably adjust the ratio of air, coal and material according to the gas concentration information of each component, so as to achieve the goal of high quality, high efficiency and low energy consumption in cement production.

Characteristics

1. The high torque pneumatic transmission device ensures that the transmission does not jam and jump.

2. Multi - stage movable section slag cleaning rod ensures smooth and stable slag cleaning action.

3. The high-strength probe rod cleaning device removes the crust regularly to ensure that the probe rod is not coking.

4. High torque rotary shaking mechanism greatly improves the thermal deformation resistance of the probe rod

5. Automatic blockage removal design ensures sampling continuity

6. Automatic protection circuit improve the stability and reliability of the product under the interference of external factors.

7. The automatic data retention function reduces the data jitter under the backblow action and improves the data smoothness

8. The automatic safety warning device sends out high decibel sound and light alarm before the probe rod moves to improve the safety of the equipment.

9. Integrated cylinder block cleaning rod design and two flexible seal to ensure that the slag cleaning rod long-term action without leakage.

10. The use of back blowing front and large flow diaphragm pump can reduce the gas displacement time after back blowing and ensure the effective data proportion.

11. Circulation large area air cooling fan heat mechanism, improve the medium heat exchange capacity. Automatic temperature control circuit and intermittent fan start and stop energy saving and consumption reduction.

12. High temperature alloy and internal rod circulation cooling system are adopted to ensure the long-term stability of the equipment in the harsh environment such as corrosion and high temperature.

Company Introduction

Hefei GoodTimes Automation Co., Ltd. is a technique oriented state-level high-tech enterprise, transformed from Hefei Jinshan Science and Technology Industrial Company organized on the basis of automation institute of Hefei Cement Research & Design Institute Corporation Ltd. under of CNBM.It was awarded the Anhui Industrial Design Center, Hefei Enterprise Technology Center, Hefei Brand demonstration Enterprise, Hefei Engineering Technology Research Center. The core team is composed of the automation laboratory of construction institute. It is a scientifific and technological enterprise with a long history and strong technical strength, which integrates scientifific research and development, equipment manufacturing, engineering settings, and technical service.The company has established a perfect quality assurance system, which has passed the authentication of ISO9001 quality management system certifification,ISO14001environment management system certifification,OHSAS18001 occupational health & safety management system certifification, level 3 work safety standardization and Certifificate for China Compulsory product certifification.It is engaged and specialized in the development of the whole series of material measurement, process control, factory power distribution and electric control, monitoring and control devices for cement production as well as their manufacturing and services. The company has inherited innovative development experience from the core team for more than 60 years. It is staffed with a professional team with fifirm grasp of the latest technology and rich practical experience. In product development, production and services, it adheres to the business concept of “Customer-centered, innovation-driven, aiming at the win-win”. The company will continue to make customers feel “carefree, assured and content"

- Q: What industry does monitoring equipment belong to?

- 1, CCTV monitoring belongs to security industry2, computer network monitoring belongs to the IT industry

- Q: What is the monitoring module?

- In programming, a program or subroutine needed to complete a function; an independent program unit that can be processed by a compiler, an assembly program, or a part of a large software system. There are various types of modules, such as the unit operation module (heat exchanger, distillation tower, compressor etc), the calculation method of the module (accelerated convergence algorithm, optimization algorithm), physical and chemical properties of the module (vapor-liquid equilibrium calculation, enthalpy calculation, etc.).

- Q: Cost difference between analog monitoring system and digital monitoring system

- First, the digital monitoring system has advantages in multi-channel video surveillance, random retrieval, playback, video and playback simultaneously, network remote monitoring, surveillance video preservation, and so on.Two, analog monitoring system, the relative cost is cheaper. The cost of digital monitoring system is 12% higher than that of analog monitoring system.

- Q: What is the IP monitoring system?

- Main equipment: the front end "webcam" is transmitted to the "NVR" via the "network cable" to the "switch", and then displayed and stored

- Q: ASUS motherboard power failure how to solve?

- Fault reason: memory alarm fault is more common, mainly caused by poor memory contact. For example, the memory is not standardized, memory is a bit thin, when the memory is inserted into the memory slot, leaving a certain gap; Goldfinger process memory of the poor, the gold finger gold plating is bad, for a long time, the surface of the oxide layer of the finger gradually thickening, lead to bad memory; the poor quality of the memory slot, Kim the finger contact reed and the memory is not really.

- Q: Which industry category does system integration belong to?

- Intelligent building system integration: English Intelligent Building System Integration, refers to the construction of intelligent building in the main body of the management system for the purpose of using integrated wiring technology, automatic control technology, communication technology, network technology, multimedia technology, security technology and other related equipment, software integration design, installation and debugging, interface custom development and application support. Including integrated wiring, building automation, telephone switches, computer engineering, monitoring system, anti-theft alarm, public broadcasting, access control system, building intercom, card, parking management, fire protection system, multimedia display system, remote conference system subsystem of intelligent building system integration and implementation of the. For the functional, approximate and unified management of intelligent building system integration of many residential buildings, it is also called intelligent residential system integration.

- Q: What are the acceptance criteria for video surveillance?

- The design of the system shall be determined according to the following factors:According to the technical and functional requirements of the system, the system composition and equipment configuration are determined;Determine the location of cameras and other equipment according to the construction plan or field survey;According to the surveillance target and the condition of the environment, determine the camera type and protective measures;According to the camera distribution and environment conditions, the routing of transmission cable is determined.

- Q: Configuration software for monitoring configuration software

- Originated from DCS (Distributed Control System distributed control system, DCS by instrument, instrument development)In the development of PLC (Programmable Logic Controller, programmable logic controller, electronic system, a digital operation for environmental applications in the industrial design); 1, InTouch:Wonderware is a business unit of Invensys PLC "production management", is a leading global provider of industrial automation software.

- Q: What is intelligent weak current engineering?

- The implementation and quality control of intelligent building weak current project is the focus of the domestic intelligent construction industry. Intelligent building systems in building environment and system integration platform, mainly through the integrated wiring system as the transmission network based channel, forming various subsystems by various kinds of weak technology and the building environment and facilities combine to form a comprehensive application, with intelligent building function requirements such as the building environment.

- Q: The security system includes a detailed analysis of what security system

- The basic configuration of the related subsystems, including front-end, transmission, information processing / control / management, display / record of four units. Different (functional) subsystems, the specific content of each unit is different.

Send your message to us

On Line Monitoring System for High Temperature Gas at Kiln Tail

- Supplier:

Hefei GoodTimes Automation Co.,Ltd.

Hefei GoodTimes Automation Co.,Ltd.

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches