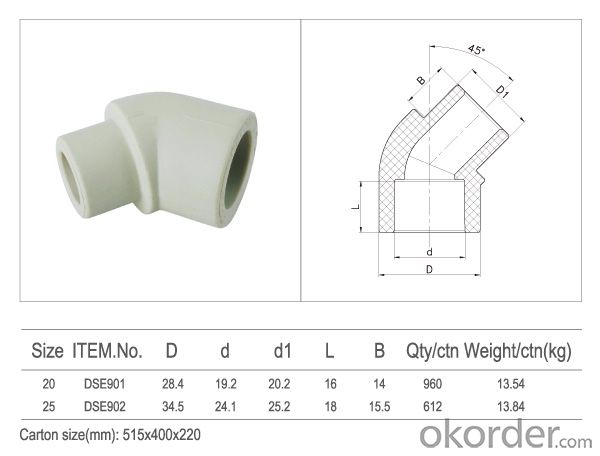

13mm Plastic Pipe Fittings - New PPR Elbow Fittings of Industrial Application Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

PP-R (polypropylene random) tube called type three polypropylene pipe and is also called the PP-R pipe or PPR pipe, with energy saving, environmental protection, high strength, corrosion resistance, with smooth inner wall has the advantages of scale, construction and easy maintenance, long service life, widely used in building water supply and drainage, urban drainage city gas and power cable sheath, and industrial fluid transportation, agricultural irrigation construction, municipal, industrial and agricultural fields. The PP-R pipe is made of random copolymerized polypropylene and is extruded into tubes to be molded into tubes.

Advantages

1)Light weight, convenient to transport and handle

2)High strength

3)less resistance

4)Corrosion resistance

5)Sound insulation

6)Easy to install

7)long lifespan

8)low cost

9)Recyclable: thereby benefiting the environment

10)OEM/ODM welcome standards

11)Reliable installation

Product Description

Product Show

Why choose us?

(1) Professional factory: We are manufacturer, specializing in manufacturing multilayer PP-R, PE pipe and PP-R, PE pipe fittings for more than13 years, our price is competitive with high quality. And we can delivery product in quick way.

(2) Sample: We can send samples out in 3 days, but the express charge usually paid by your side, but the fee will be rebound when we have formal order.

(3) Rapid response to your needs: We will be answer within 24 hours. Welcome to contact with us if you have any problems. We are looking to cooperating with you.

(4) We hope we can establish long-term and mutual benefit business relation with you. If you have any problem, please kindly feel free to contact me. I will try the best to help you!

- Q: What are the common sizes of plastic pipe fittings?

- The common sizes of plastic pipe fittings vary depending on the type of pipe system being used. However, some commonly used sizes include ½ inch, ¾ inch, 1 inch, 1 ¼ inch, 1 ½ inch, and 2 inches.

- Q: Can plastic pipe fittings be used for sewer and wastewater systems?

- Yes, plastic pipe fittings can be used for sewer and wastewater systems. Plastic fittings, such as PVC or ABS, are commonly used in these systems due to their durability, resistance to corrosion, and ease of installation. They are also cost-effective and offer a long lifespan, making them a popular choice for sewer and wastewater applications.

- Q: Can plastic pipe fittings be used for gas lines?

- No, plastic pipe fittings should not be used for gas lines. Gas lines require materials that are specifically designed to handle the high pressure and potential hazards associated with gas, such as corrosion and leaks. Metal pipe fittings, such as those made of steel or brass, are typically recommended for gas line installations to ensure safety and compliance with relevant building codes and regulations.

- Q: Are plastic pipe fittings compatible with solvent welding?

- Yes, plastic pipe fittings are compatible with solvent welding. Solvent welding is a common method used to join plastic pipe fittings together by applying a solvent cement that chemically melts the surfaces of the fittings, creating a strong and durable bond.

- Q: Can plastic pipe fittings be used in water slide systems?

- Yes, plastic pipe fittings can be used in water slide systems.

- Q: PVC what's the direct head of the outside pipe?

- PVC water supply pipe and wire directly, as with the pipe connection. As regards the fittings in this area, you can take information from Asia / Johnson / plastics. I hope my answer will help you.

- Q: Are plastic pipe fittings easy to disassemble and reassemble?

- Yes, plastic pipe fittings are generally easy to disassemble and reassemble. They are designed with a simple push-fit or threaded connection system, allowing for easy removal and reinstallation without the need for specialized tools.

- Q: Can plastic pipe fittings be used for freshwater aquaculture systems?

- Yes, plastic pipe fittings can be used for freshwater aquaculture systems. Plastic pipes and fittings are commonly used in aquaculture systems due to their durability, resistance to corrosion, and ability to withstand varying water conditions. These fittings are typically made from materials such as PVC or polyethylene, which are safe for freshwater environments and can effectively transport water within the aquaculture system.

- Q: Who knows the size of the PVC pipe and what is the maximum and minimum size?

- Because of its harm to human body, Europe, Japan and South Korea and other countries have restrictions on using PVC as raw material and products. PVC resin has the advantages of plastic products is generally difficult to burn, abrasion resistance, chemical resistance, low leakage, good gas vapor. In addition, comprehensive mechanical energy, products transparent, electrical insulation, insulation, noise elimination, shock elimination, or better, is the most superior price than the general type of material. The defect is thermal stability and shock resistance is poor, whether it is hard or soft, PVC is easy to produce brittle during use. General PVC is not containing the relevant national standards allow the use of two (2 - ethylhexyl) adipate plasticizer (DEHA), DEHA in the high temperature (over 100 degrees Celsius) easily released, after contact with human health hazard. Because PVC is a hard plastic, to make it soft, a large amount of plasticizers must be added. Plasticizers are easy to release in a heated environment. If you are using DEHA, it will interfere with the human endocrine, cause women to breast cancer, birth defects, reduce the number of male sperm, or even mental disorders.

- Q: Can plastic pipe fittings be used for rainwater diversion systems?

- Yes, plastic pipe fittings can be used for rainwater diversion systems. Plastic fittings are commonly used in such systems due to their durability, affordability, and resistance to corrosion. They are also lightweight and easy to install, making them a popular choice for rainwater diversion projects.

Send your message to us

13mm Plastic Pipe Fittings - New PPR Elbow Fittings of Industrial Application Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords