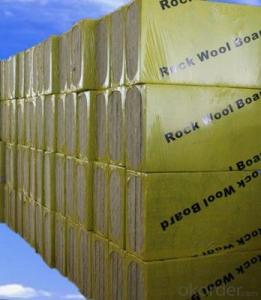

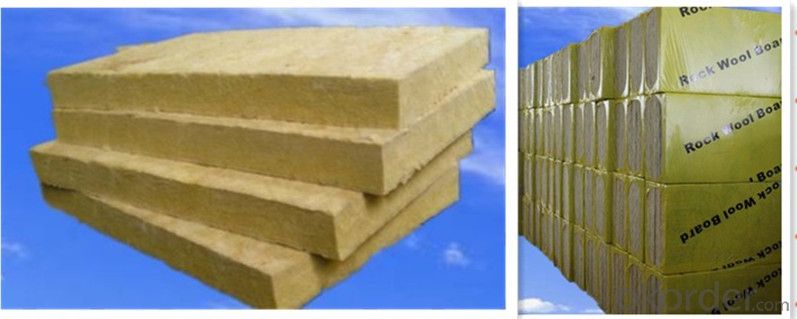

Competitive Rock Wool Nature Basalt Partition

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 800000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

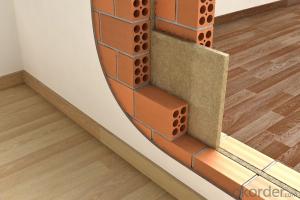

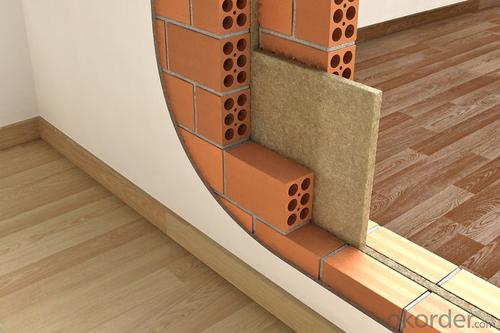

Rock Wool are made from natural rock such as basalt and dolomite. The natural rock are melted into melts in cupola at a very high temperature about 1500℃. And the melts lava is then pour to high speed spinners through which the melts get into fibers. At the same time, the phenolic binder containing silicon and mineral oil etc are sprayed onto the surface of each fiber homogeneously. The just fiberized fibers are collected together to form the original wool mat through negative pressure resulted from suction. The original wool mats then pass through pendulum, crimping and pressing process, get into the curing oven through which the wool mats are cured and shape up to different kinds of products such as board, mat and pipe section etc with different usage.

● FEATURES

● Thermal Insulation ● Fire Safety ● Acoustic Control

● No Corrosion ● Environmental friendly ● Moisture Resistance

● Energy Conservation & Emissions Reduction

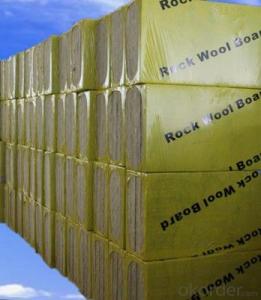

Standard Size

Product Board and Blanket

Size: L x W (mm) 600X1200, 600 X5000

Density: 60KG/M3- 150KG/M3

Main Features:

• Light weight • Enough Density

• Thermal Insulation • No Corrosion

• Energy Conservation • Competitive Prices

• Cost Effective • Large Capacity

• Short Lead time • Large Capacity

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Mineral Wool,is one of the large-scale professional investment mineral production bases in China, consisting of both rock wool and mineral wool factory. Annually more than 8000 tons. Rock wool are exported to markets in Asian, American, Middle East, African. OEM service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within one week days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly two weeks working days can be served.

- Q: What does the rock wool board look like?

- Rock wool board to basalt as a material, after high temperature melting processing into artificial inorganic fibers, with a light weight, thermal conductivity, heat absorption, non-flammable characteristics

- Q: What role does dolomite play in rock wool products?

- Pu hard foam layer can be firmly bonded with the base layer, the adhesive strength can exceed the tear strength of the foam itself, so Pu hard foam and the formation of the base layer, easy to delamination, to avoid the water along the interlayer

- Q: Rock wool products are divided into several categories

- Rock wool with a light weight, non-combustible, small thermal conductivity, sound absorption performance, good chemical stability and so on

- Q: How to judge the quality of rock wool

- Appearance and quality: Choose the material surface smooth and beautiful, no stains, no damage to the material

- Q: The difference between rock wool and rock wool

- Yanmian tube with high strength and good flexibility, with a certain pressure, the pleated treatment of rock wool tube with a large drawing strength, not easy to layer, greatly improving the durability of the durability

- Q: Rock wool products and aluminum silicate acupuncture blankets are same

- No, rock wool is ore blown wire, aluminum silicate is coke gem

- Q: Rock wool insulation material fire rating is how much

- Rock wool insulation material fire rating is how much

- Q: Rock wool board is inorganic composite insulation material

- Rock wool products are inorganic insulation materials

Send your message to us

Competitive Rock Wool Nature Basalt Partition

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 800000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords