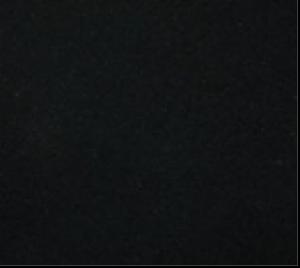

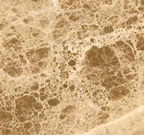

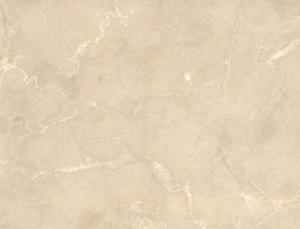

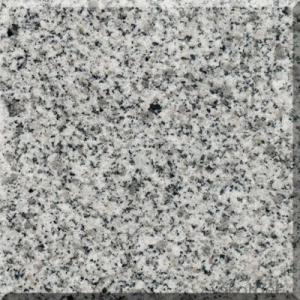

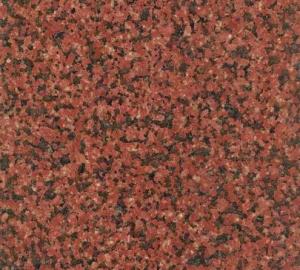

Natural Granite Interior Exterior Stone for Decoration

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Dimension | Slabs | 600upx1800upx20~30mm | |

700upx1800upx20~30mm | |||

1200upx2400~3200upx20~30mm | |||

Tiles | 305x305mm(12"x12") | ||

300x600mm(12"x24") | |||

400x400mm(18"x18") | |||

600x600mm(24"x24") | |||

Thickness | 10mm(3/8"),12mm(1/2"),20mm(3/4"),etc. | ||

Also Available | According to your requirement | ||

Packaging Details | Strong fumigated wooden pallets for export. | ||

Delivery Time | According to your purchase quantity. | ||

M.O.Q. | One 20' Container | ||

Quality Assurance | During the whole production process, from raw material choosing, fabrication to package, Our quality controller will strictly inspect each pcs and control each process to ensure quality standards and timely delivery. | ||

(1)Terms and Services

1,Price terms:FOB,CIF,CNF

2,Payment terms:T/T or L/C at sight,and Western Union if it is samples

3.Loading port:Xiamen 、 Qingdao or Any China Port.

4,MOQ: 1x2ft with mixed style container,sample order is negotiable

5,Package: Fumigated seaworthy wooden crates with plastic and foam inside

6,Delivery : Within 10-20 days,depengs on customers' order quantity

(2)Quality Assurance

During the whole production process,from material choosing, fabrication to package,our quality auditors will strictly control each single and every process to ensure quality standards and punctual delivery.

(3)Shipping Service

We can arrange transportations for you,or you can choose the one you like,Timely and delivery is our service tent

(4) Packing and loading

| For tiles | plastic foam inside, fumigated strong wooden crate outside, reinforced with metal strap |

| For slabs | Seaworthy fumigated strong wooden bundle |

| Shipping | Our professional service team in Xiamen is able to provide FCL and LCL shipment with competitive cost |

- Q: Can the limestone in instant rice be reused?

- Limestone in a certain period of time can be reused, and its main function is to absorb the free water molecules in the environment, the reaction CaO+H2O=====Ca (OH) 2

- Q: Wan Feng stone products in the end how?

- Ha ha very good my home is the background of Wan Feng's green jade with the background of the wall made by Huang Longyu, the effect is very good, installed last year, it seems to spend more than 10 thousand of the look

- Q: Do you need to do radioactivity test?

- In the process of imported stone, commonly encountered an import customs clearance? Stone import needs the owner to provide import stone time, port, the import of the goods name, import stone gross and net weight, volume, stone value, and the specific number, description of goods and use, and then according to these data, making our declaration arrange customs declaration documents, on-site delivery customs declaration, using our in port and shipping, customs, customs clearance, warehousing, port trailers and other logistics resources, the fastest time for customer inquiries stone, customs import pricing stone, provide fast port inspection, declaration, customs clearance for customers to save terminal fees, rent cabinet other expenses.

- Q: Which is more environmentally friendly, man-made marble and natural marble

- Artificial is not suitable for the ground is easy to scratch, and man-made chemical synthesis, not on the contrary, harmful to the human body and easy to deformation. Granite granite should be used to improve the hardness and wear resistance of the high gloss look up to a lot of high-end. Marble quality soft not suitable for ground. As you said radiation that is the tile and wood flooring industry to fight opponents rhetoric. Some of the early radiation is indeed excessive, but now there is no excessive circulation in the. Many of the varieties were not allowed to be mined many years ago. Radiation has a lot of things in this place, on their own side of the surrounding space is full of signal radiation. Radiation as long as there is no harm to the human body in the safe range.

- Q: How to splice artificial marble table

- The use of special glue, with fixture fixed, completely cured after polishing, polishing.

- Q: There are several decorative stone? What kind of natural stone and characteristics of it?

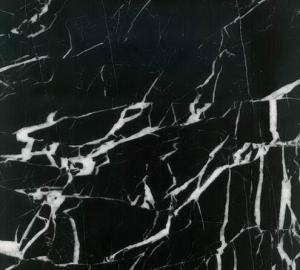

- Granite is igneous, from the underground magma jet and intrusion cooling crystallization, and granitic metamorphic rocks formed. With visible crystal structure and texture. The granite has a specific gravity between 2.63 and 2.75 and has a compressive strength of 1,050 to 14,000 kg / cm? (15,000 to 20,000 psi). Because the strength of granite than sandstone, limestone and marble, so more difficult to mine.

- Q: How to build the family decoration sandstone

- Can be hung dry, suitable for large size facade paste, the average thickness of more than 15mm; dry hang solid durable;

- Q: What does the granite mean?

- The general use of granite Granite unique physical characteristics with its beautiful pattern so that he became a good material for the building, known as "the king of the rock," said, there are people with a concept, two, three, four to evaluate good or bad. In the building granite can be used from the roof to the floor, the sidewalk of the curb is, if it crushed can also be made of cement or rock fill dam. Many places or items that require wind and rain or need to be kept are made of granite. Like the Taipei "Chiang Kai-shek Memorial Hall" brand and the Beijing Tiananmen Square People's Heroes Monument are made of granite. Granite after thousands of years is still the enduring characteristics of the famous Egyptian pyramid to prove this point.

- Q: Why is calcined limestone not exothermic?

- It needs heat to break downSo need to absorb heatCalcined limestone does not belong to combustion

- Q: Natural stone is not marble

- Natural stone is a kind of stone which contains a wide range of stones.

Send your message to us

Natural Granite Interior Exterior Stone for Decoration

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords