Cryogenic Insulation Paper for Multilayer Heat Insulation Cover for LNG or LPG

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

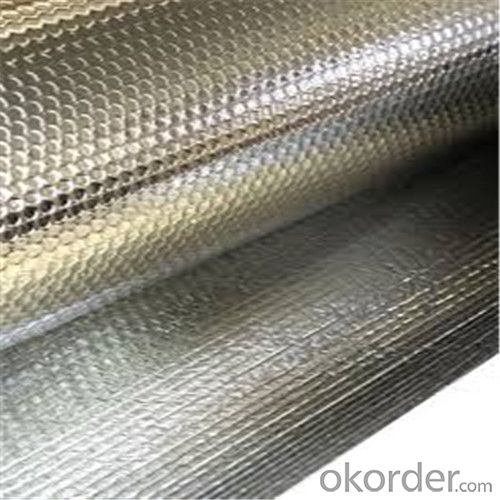

Quick Details for Aluminum Foil Laminated Cryogenic Insulation Quilt or Paper

| Place of Origin: | Jiangsu, China (Mainland) | Brand Name: | HAOLIS | Model Number: | customized |

| Application: | Cryogenic liquid container() | Surface Treatment: | raw material | Technique: | vacuum aluminium |

| Dimensions: | 10-14g/m^2 | color: | white | material: | glass fibre paper and aluminium foil |

| working temperature: | -269℃-500℃ |

Packaging & Delivery

| Packaging Details: | in roll/ in cartons /in bales 1. Tarpaulin Rolls: 20GP Load around 15tons. 2. Bale packing: 20'GP Load around 10 Tons , 40'HQ Load around 25 Tons. 3. Carton packing: 20'GP Load around 8 Tons , 40'HQ Load around 22 Tons. |

| Delivery Detail: | 10-20days after payment |

Specifications

Aluminium foil/film+pe woven cloth( single alu)

Aluminium foil/film+ pe woven+ aluminium foil(both sides alu)

Characteristics:

No odor and to xicity, environmentally-friendly;

Light, soft, dustfree, fire, retardant, easy to install;

Heat reflection, heat insulation, sound insulation, anti- radiation, anti- vibration, and shielding;

high Adhesion Strength super Holding Power good Conductivity CTI certificated.

Application

1.As heat and light (radiant) barrier for the roofing of housing;

2.As the interlayer between floor and the ground to prevent moisture and heat;

3.As an disposable and budget underlay insulation material for carpets;

4.As protective outer package for industrial machines, vehicles and home appliance

UV additive can be added according to different requirement.

FR additive can be added according to different requirement, FR standard can reach US CPAI-84 FR7 standard.

* Note : These are our standard specifications but products with customized specifications are also available.

- Q: I would like to ask how the process of cryogenic treatment

- Biology: fast cooling, can prevent the crystallization of cells in the water, does not destroy the cell organization. In the preservation of sperm, organ preservation, food preservation, preservation of certain life and so onMedical treatment: cryotherapy, treatment of certain skin diseasesSpace: the space environment simulation, satellite ground test station, using liquid helium, create -200 degrees of low temperature.Noise: high sensitivity radar telescope, using liquid helium cooling, receiving device, noise reductionVacuum: the use of cold well technology can get high vacuum

- Q: Can the cryogenic phase control the cooling rate?

- If it is just a simple container or box, it is difficult to control the temperature. The program can control the temperature of cryogenic equipment, can also control the cooling rate

- Q: How many changes in the properties of the cryogenic metal?

- 4 milling cutter milling hole surface Phi 12, 48-2NT5 milling cutter milling end 13, 48-2NT6 high speed steel twist drill drilling A3 of 129 2967 high speed steel twist drill drilling 40Cr of 146 3588 high speed steel 8 drill wear 25cr2NiMoV 10 hole 40 hole wear9 high speed steel 10 bit hour HT20-40 1235

- Q: Cryogenic treatment to improve what performance?

- Cryogenic treatment (cryogenic treatment) refers to the materials needed at -190 DEG C to -230 DEG C under treatment. Suitable for all metal or nonmetal material, such as alloy, carbide, plastic (nylon and Tie Fulong), aluminum, ceramics etc..

- Q: Ultra low pressure casting mold useful, how to arrange the process? Thank you

- Ultra deep cryogenic treatment process is mainly to eliminate the uneven stress in the process of heat treatment!Cryogenic treatment is mainly to eliminate internal stress or even internal stress! Can play a role in stabilizing the size!

- Q: What is the meaning of vacuum cooling in heat treatment

- Placed for a period of time, known as cryogenic treatment, under normal circumstances are usually treated with liquid nitrogen.

- Q: What is a cryogenic fast line

- Cryogenic metal industry technology refers to the black metals, nonferrous metals, polymers, carbide and so on at cryogenic temperature heat preservation material, make it happen at room temperature and never happened in the process of heat treatment of the internal structure change, lead to the change of macro performance. For example: die steel, high speed steel, cemented carbide strength and toughness were improved after cryogenic treatment, and break through the traditional hardness and toughness of contradictory phenomenon, show the comprehensive performance improved. Domestic contribution to cryogenic technology research institute of Chinese academy of sciences, is the biggest should from the several aspects, such as equipment, mechanism, process research and extension of cryogenic technology, cryogenic in cutting tools, moulds, valves, and other industries extensively with the Chinese academy of sciences of physics and chemistry ? all the inseparable relations

- Q: What is the meaning of cryogenic technology in the mechanical process, what is the specific practice?

- Treatment of -130 DEG C is said to be a new and strong treatment process of cryogenic treatment to improve the wear resistance and toughness of materials and to improve the overall service life

- Q: What is the meaning of deep frozen

- So people use frozen ways to preserve food. Generally in a very short period of time, such as half an hour, so that the need to freeze the food quickly reach the specified ultra-low temperature, such as -30 ~-40 C.

Send your message to us

Cryogenic Insulation Paper for Multilayer Heat Insulation Cover for LNG or LPG

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches