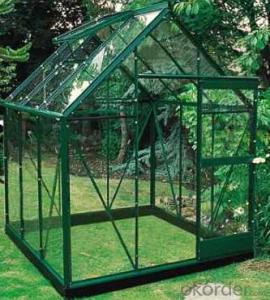

Multi span vegetable greenhouse for sales

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1. poly film greenhouses

2.Large inner space utilization

3.Easy to manage and maintance

Greenhouse Introduction:

Multispan plastic film arch greenhouse is special designed for the area where has relative higher temperature in winter. Through the strict compression test, the greenhouse shows an excellent performance, especially in the heavy windy area. The covering plastic also allows very good transmission of the sunlight.

1. Framework Structure: Hot dipped galvanized steel structure.

This kind of special treated steel has good anticorrosion and antirust effects, which extends the service life of the greenhouse. Special designed structure and accessories make sure the outstanding performance of the greenhouse.

2. Covering Material: Single Layer PE Film

Single Layer PEP Long Life Film is tri-extruded by the anti-UV layer, anti-static layer and anti-dripping layer. It has the good quality of high light transmission, warm-keep, high light reflection, anti-dust, anti-dripping, anti-fog, insect-proof, long life and large size etc. The quality guarantee is 1 and half year, the life time could be at least 5 years under normal condition.

- Q: What are the advantages of using plastic weed barrier fabric in landscaping?

- Plastic weed barrier fabric in landscaping offers several advantages. Firstly, it helps to prevent the growth of weeds by blocking sunlight and impeding their growth. This saves time and effort in weed maintenance. Secondly, it acts as a protective layer, preventing soil erosion and maintaining moisture levels in the soil. Additionally, it aids in temperature regulation, helping plants to thrive in both hot and cold climates. Lastly, plastic weed barrier fabric is durable and long-lasting, reducing the need for frequent replacements and ensuring cost-effectiveness in the long run.

- Q: Can ground cover plants be used to replace traditional groundcovers like grass?

- Yes, ground cover plants can be used as an alternative to traditional groundcovers like grass. They offer several advantages such as reducing water consumption, preventing soil erosion, providing habitat for beneficial insects, and requiring less maintenance. Additionally, ground cover plants come in various colors, textures, and heights, allowing for creative and aesthetically pleasing landscape designs.

- Q: This question asks if farmers can incorporate bioplastics into their agricultural practices.

- <p>Yes, farmers can use bioplastics in their production processes. Bioplastics are derived from renewable biomass sources, such as plants, and can be used in various agricultural applications. They are biodegradable and can reduce the environmental impact of traditional plastics. Farmers can use bioplastics for mulching films, plant pots, and packaging materials, which can help in soil conservation, water retention, and reducing plastic waste. However, the adoption of bioplastics in agriculture is still growing, and their effectiveness and economic viability can vary depending on the specific context and application.</p>

- Q: How are plastic tree guards assembled and installed?

- Plastic tree guards are typically assembled by connecting the individual panels or sections together using interlocking mechanisms or clips. Once assembled, they are then installed around the base of the tree by placing them firmly in the ground or attaching them to stakes or posts.

- Q: Can nursery trays be used for starting groundcover cuttings?

- Yes, nursery trays can be used for starting groundcover cuttings. Nursery trays are designed to provide a suitable environment for seed germination and rooting of cuttings. They often have individual cells or compartments that can hold the cuttings and provide the necessary support and moisture retention. Additionally, nursery trays are usually equipped with drainage holes to prevent waterlogging, which is essential for the successful establishment of groundcover cuttings.

- Q: How do you fix a crack in a plastic bumper cover?

- go to a prts store such as NAPA or advanced auto parts and buy a repair kit for bumpers such as SEM or Fisor, take bumper off follow instructions

- Q: do all landfills have plastic in them? and if its a state law, what states allow the dumping of plastics into landfills?

- in the Philippines plastic is removed by hand as it is thrown from the garbage lorries. it is the sold to those who recycle plastics

- Q: Can nursery trays be used for olive tree propagation?

- Yes, nursery trays can be used for olive tree propagation. Nursery trays provide a suitable environment for starting olive tree cuttings or seeds and allow for efficient seedling growth and root development.

- Q: How do agricultural plastic products help with hydroponic deep water culture?

- Agricultural plastic products assist with hydroponic deep water culture by providing a variety of benefits. Firstly, plastic materials like polyethylene are commonly used to construct hydroponic systems, such as nutrient reservoirs, grow trays, and pipes, due to their durability and resistance to water. These plastic components effectively contain and distribute the nutrient-rich water solution to the plants' roots. Additionally, plastic films and covers can be employed to create greenhouse structures, which help maintain an optimal growing environment by regulating temperature, humidity, and light levels. Furthermore, plastic mulches can be spread on the surface of the water to prevent algae growth and reduce evaporation, thereby conserving water and improving the efficiency of nutrient delivery. In summary, agricultural plastic products play a crucial role in facilitating hydroponic deep water culture, enhancing plant growth, and maximizing productivity.

- Q: i dont know what plastic is made of and will we ever run out.

- . Petroleum is drilled and transported to a refinery. 2. Crude oil and natural gas are refined into ethane, propane, hundreds of other petrochemical products and, of course, fuel for your car. 3. Ethane and propane are cracked into ethylene and propylene, using high-temperature furnaces. 4. Catalyst is combined with ethylene or propylene in a reactor, resulting in fluff, a powdered material (polymer) resembling laundry detergent. 5. Fluff is combined with additives in a continuous blender. 6. Polymer is fed to an extruder where it is melted. 7. Melted plastic is cooled then fed to a pelletizer that cuts the product into small pellets. 8. Pellets are shipped to customers.

Send your message to us

Multi span vegetable greenhouse for sales

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords