Mineral Fiber Ceiling Tile Asbestos-Free 600x600mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Mineral Fiber Ceiling) Description

Mineral fiber Ceiling

Thickness: 6.4mm-16mm

Size:595X595mm, 595X1195mm

Color: White

Over 20 patterns design*

2,Main Features of the (Mineral Fiber Ceiling)

key performance

Economical with good acoustics

Nondirectional visual reduces installation time and scrap

Reliable with proven performance

Mold resistance

No Asbestos

No Formaldehyde

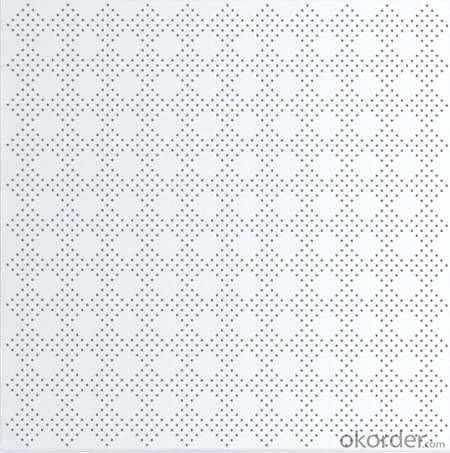

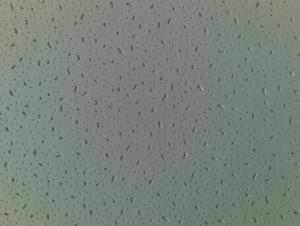

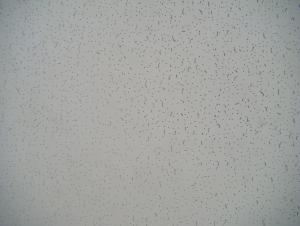

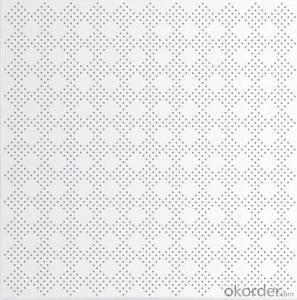

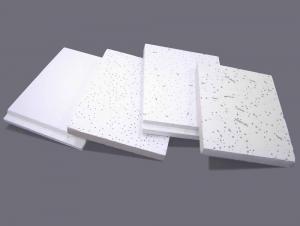

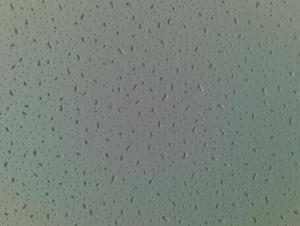

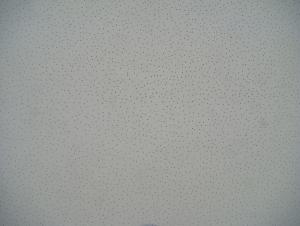

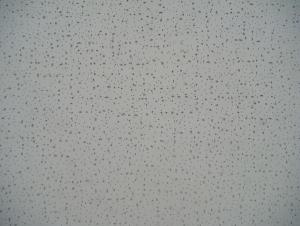

3,(Mineral Fiber Ceiling) Images

4,(Mineral Fiber Ceiling) Specification

The specifications of Mineral Fiber Ceiling Tiles:

Product | Mineral Fiber Board Ceiling Tiles |

Material | Mineral wool |

Thickness | 6.5mm-30mm |

Size | 300X600mm, 300X1200mm, 300X1800mm, 400X1200mm, 400X1800mm, 600X600mm, 600X1200mm, 600X1800mm |

Color | White |

Pattern | Over 20 patterns design |

Edge | Beveled, Concealed, Glacier, Transcendent Mortise Bolt, Regular, Perforated |

MOQ | 1X40HQ |

Specification:

Material | Wet Formed mineral fiber |

Surface | Factory Applied Vinyl Latex Paint |

Noise reduction coefficient | NRC 0.4-0.6 depending on the surface patterns |

Humidity Resistance(RH) | >=80% |

Light reflectivity | >=85% |

Fire Performance | non-combustible,reach class A according to GB8624-1999 |

Moisture resistant | conform to the quality requirements of standard board(12mm,14mm) according to JC/T670-2005 |

Environmental protection | no asbestos,formaldehyde content<0.1mg/L |

Acoustical performance | comply with the requirements of JC/T670-2005 |

Colour | white |

Density | 280-320kgs/m3 |

Dimension | 300x600mm, 300 x 1200mm, 600x600mm, 600x1200mm etc |

Edge finish | square edge, tegular edge, adhesive and nails edge, concealed edge, shiplap edge, and liner shiplap edge. |

Thickness | 12mm, 14mm, 15mm, 16mm,18mm, 20mm etc. |

Product Feature | Sound absorbing,Resistance to fire, warm-keeping, energy-saving, heat-insulating |

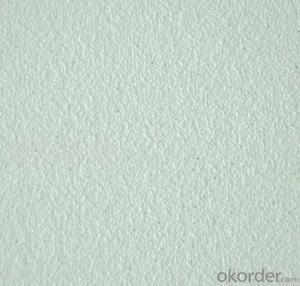

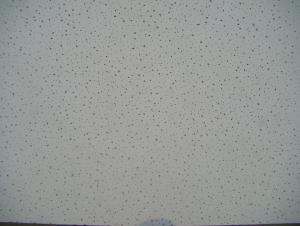

Pattern | Pine holes,Little-Stars,Lovely-Worms,Sand Surface,and other special designs |

Other | Mold resistance No Asbestos No Formaldehyde |

5,FAQ of (Mineral Fiber Ceiling)

2. Product Feature:

Sound absorbing

Resistance to fire

warm-keeping

energy-saving

heat-insulating,

sag resistance.

3. performance index

Fire performance:non-combustible,reach class A according to GB8624-1999.

Moisture resistant: conform to the quality requirements of standard board(12mm,14mm)according to JC/T670-2005.

Enviromental portection:no asbestos,formaldehyde content<0.1mg/L

No rediation, conform to the requirements of GB6566-2001 for Class Amaterials

Acoustical performance:comply with the requirements of JC/T670-2005

- Q: Uvp decorative plate for home improvement?

- Hello, uv board decoration is not suitable for home improvement, the general applies to bars, high-end mall, villas and ktv!

- Q: Indoor roof decoration materials which

- At present, the commonly used ceiling decorative panels are plaster ceiling decorative panels, plaster gypsum decorative panels, embedded decorative gypsum board, fire pearl gypsum board, calcium plastic foam decorative panels, PVC micro-foam decorative panels, mineral wool decorative sound Board, glass wool decorative sound-absorbing panels. In addition to these decorative materials with excellent decorative effect, usually also has a fire, sound absorption, noise, heat insulation, moisture and other advantages.

- Q: Do you think this new UV decorative board market? Do you think this new UV decorative board market? I know a new type of UV decorative board (cement

- At present in the country to use the brand on the US brand UV board manufacturers reached 20 percent, you can see the UV board in the market demand is very impressive.

- Q: How can we find out if the car is equipped with GPS

- Direct search of the car, we all know, the general GPS are installed in the car on these locations, you can first look at these locations to see if there is: the front windshield above the roof lights, the front windshield below Decorative panels within the shelter, the front dashboard around the shelter, the door partition, under the windshield below the decorative panels, the front bumper inside, wipers board.

- Q: Plastic decorative plate of plastic decorative plate of raw materials

- (1) single-sided decorative panels (2) double-sided decorative panels 1. Surface paper 2. Decorative paper 3. Cover paper 4. Bottom paper (several layers) 5. Isolated paper base paper and the underlying paper, impregnated with oleic acid under the bottom of the paper to prevent the phenolic resin in the hot pressing process Stick to the aluminum plate. A polypropylene film can be used to coat the aluminum backing plate to remove the release paper.

- Q: Do you want to use uv decorative panels for external walls?

- Outside the wall with UV decorative plate is not very good, will fade the price is also high

- Q: Crystal furniture crystal trim is not really true

- Crystal plate: the brightness of the surface, so named "crystal plate." Substrate with MDF or particleboard, the surface paste "plexiglass plate", the thickness of about 2-3mm. Paint before painting, so that after forming the plate with a variety of color changes. Crystal plate wear, scratch, flame retardant performance is poor, but not with compression performance. Sensitive to temperature, and even spotlight long-term exposure to the local color will change. Crystal plate processing technology is simple, painted by paint, paste, edge, a little polished can be polished. Raw material costs slightly lower than the refractory board, for low economic income of the people is also a viable option.

- Q: What is the relationship between Li Mei diatomian decorative plate and natural home diatom mud?

- Are diatom mud board

- Q: New fire decorative panels who know what brand? The The Which is good?

- Carefully observed, in the surface of the single version and the substrate between the layers of the substrate can not appear between the drum package, layered phenomenon. Glue and strength fully reflects the advantages and disadvantages of the bonding properties of the board, gluing strength is about high, the better the gluing performance. Jin Luli, Moganshan, Shuangliang, the new sun and the moon XRY, bunny, the Millennium boat these are good

- Q: Translucent decorative panels, materials, acrylic and polyester differences

- Not the price to be more expensive, excellent West is the use of imported polyester material, you can ask

Send your message to us

Mineral Fiber Ceiling Tile Asbestos-Free 600x600mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords