Metrocopo Tile Forming Machine For Aluminum Coils with ISO Quality System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Metrocopo Tile Roll forming machine

Technical data of metrocopo tile roll forming machine

Suitable Material | Q235 color steel sheet;0.4-0.6mm | |

Working speed | About 3.0m/min | |

Step distanc | adjustable according to requirement (>=250mm) | |

Power Requirement | Main motor power: 5.5 Kw(Depend on final design) | |

Hydraulic station power: 5.5Kw(Depend on final design) | ||

Material of forming rollers | No.45 steel, plated with chrome on surface. | |

Material of cutter,pressing die | Cr12 mould steel with quench treatment, HRC58-60 | |

Material of shaft | High quality 45# steel, Dia. is 72mm. | |

Shaft diameter | 72mm | |

Controlling system | Mitsubishi PLC & converter | |

Total weight of machine | About 10500KGS | |

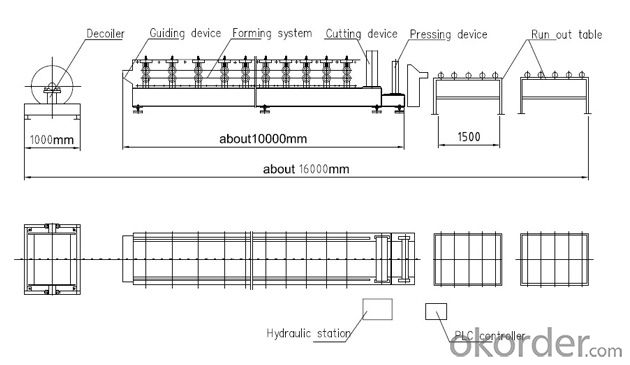

Machine''''''''s size | About 18m×1.8m× 1.5m (Depend on final design) | |

Layout drawing of machine

Our Metrocopo Tile Roll Forming Machine’s advantages

| 1. Anti-rust roller: CNC machine tooled, Plated with 0.05mm hard chrome . 2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation. 3. Cutter blade: Cr12 mould steel with quenched treatment, long life time. 4. High precision: shafts for rollers are tooled by grinding machine at least twice. Rollers are CNC processed to ensure precision performance. 5. People originate: introduced Mitsubishi PLC with touch screen. Friendly man-machine interaction. 6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifttime services for our machines. |

- Q: Say that China's machine is not good, then they are sold to whom?

- But into the field of precision machining, domestic machine tool precision level and degree of automation than imported machine tools or no small gap.

- Q: What are the types of machine tools?

- Machinable range is very wide, rotary body, spiral body, plane, groove, gear and so on.

- Q: What is the main part of CNC machine tools?

- CNC machine work, do not need workers to directly operate the machine, to control the CNC machine tools,

- Q: What is rocker machine, gantry machine? Are these two types of machines belonging to the same classification method? Are there any other machine tools in this category?

- Are these two types of machines belonging to the same classification method?

- Q: Why is the CNC lathe so precise, what is it?

- In summary, so CNC lathes compared with the traditional lathe, the machining accuracy has been greatly improved.

- Q: CNC lathe programming g90 what it means

- HNC CNC lathe G90: absolute value programming.

- Q: The basic structure and function of machine tools

- 1, supporting parts for the installation and support of other parts and workpieces, to withstand its weight and cutting force, such as bed and pillars;

- Q: Compared with ordinary machine tools, how to look at the inevitable emergence of CNC machine tools

- Second, the accuracy of CNC machine tools can be used to achieve a clamping a number of surface processing to ensure the consistency of the size.

- Q: What is the machine?

- Machine is the machine that makes the machine, also known as the machine tool or machine machine, used to be referred to as machine tools.

- Q: Other types of CNC machine tools for what occasions?

- Independent: independent of the CNC device, with complete hardware and software functions, can independently complete the provisions of the control task of the device.

Send your message to us

Metrocopo Tile Forming Machine For Aluminum Coils with ISO Quality System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches