Metallurgical Coke of Coke Strength after Reactivity 65

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Met Coke of Coke Strength after Reactivity 65 Description:

Coke is made by high temperature metallurgical coke for blast furnace smelting, casting and gasification. Occurring in the process of coking after recovery and purification of coke oven gas is a high calorific value of fuel, is an important industrial raw material in organic synthesis.

Our country's metallurgical industry has a long history, is the original fuel charcoal smelting industry, due to the charcoal burning temperature is lower, and short duration of fire and not easy to master hour, therefore, directly affect the level of smelting, to make the steel quality is not guaranteed. Later, people use coal as smelting, coal combustion temperature is higher, and the combustion duration is longer than charcoal, but easily broken after coal is heated in the oven, affect the burden of permeability, and high content of sulfur in coal, directly affect the quality of the cast iron. After a period of practice, it has been found that the coal after dry distillation (i.e., separated flame heating), volatile components may be removed, and the porosity increased, resembling charcoal, fire is better than that of coal, but also can avoid charcoal and coal. This after carbonization of coal is coke.

2. Main Features of the Met Coke of Coke Strength after Reactivity 65:

• Quality assurance

• Mutual benefit

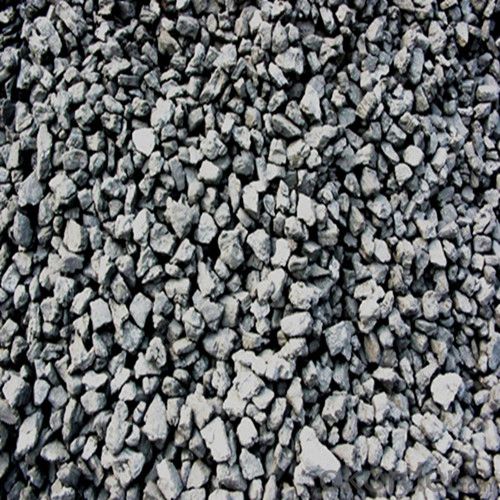

3. Met Coke of Coke Strength after Reactivity 65 Images:

4. Met Coke of Coke Strength after Reactivity 65 Specification:

Parameters | Guarantee | Rejection |

Total Moisture (As received basis) | 5% max | |

Ash (dry basis) | 12.5% max | > 13.5% |

Volatile Matter (dry basis) | 1.5% max | > 1.8% |

Sulphur (dry basis) | 0.65% max | > 0.75% |

Phosphorus (dry basis) | 0.035% max | > 0.045% |

M10 | 7% max | > 9% |

M40 | 84% min | <82% |

CSR | 65% min | <63% |

CRI | 25% max | > 27% |

Size 30-90 mm | 90% min | |

+90 mm | 5% max | > 8% |

-30mm | 5% max | > 8% |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

1) What are coke's main physical properties?

on the relative density of density, coke, coke porosity, thermal conductivity for the heat capacity of coke, coke, coke, coke ignition temperature, coke thermal expansion coefficient of thermal stress and coke, coke shrinkage rate, coke resistivity permeability, etc.

The average heat capacity is 0.808 kj/(KGK) (100 ℃), 1.465 kj/(KGK) (1000 ℃)

Thermal conductivity is 2.64 kj/(MHK) (room temperature), 6.91 kj/(MHK) (900 ℃);

Ignition temperature (air) is 450-650 ℃.

2)Main type

Metallurgical coke is blast furnace coke, coke, iron alloy and nonferrous metal smelting with coke. As more than 90% of the metallurgical coke for blast furnace ironmaking, so often called the blast furnace coke metallurgical coke.

Foundry coke is dedicated to cupola molten iron. Coke is the main fuel of cupola molten iron. Its role is hot metal melting furnace charge and overheating, support stock column maintain its good air permeability. As a result, coke blocks should have large, low reactivity, low porosity, with sufficient impact crushing strength, ash content and low sulfur content.

In China, "natural coke" used as a fuel. Underground coal seam spontaneous combustion, and can also form natural coke. Natural coke, the grey to dark grey color, more porous, can sometimes show hexagonal prism shape. Compared with artificial coke, weight big, small porosity, density.

- Q: The difference between coal and coke

- The production of coke products in general is mainly based on high temperature carbonization, and the carbonization temperature usually needs about 1000 degrees celsius. After years of development, the current large-scale coke furnace equipment and technology is relatively mature, have equipment to improve the yield so as to achieve large-scale production conditions, coke furnace built in recent years, each with a yield of about 500 thousand tons, the highest can be even more than 1 million tons / year, such as the recent launch of mine international coking plant two chamber coke oven 7.63 m, each with a yield of 1 million 100 thousand tons per year.

- Q: What is cokeWhat applications are, what is the fire of Malachite copper

- Coke is used for heating, and coke is also used as a reducing agent to process the iron ore, the oxide ore, the malachite is the copper oxide

- Q: Ask: coking coke tower tower and what is the relationship?If you can give a working principle to explain what is better!Coking tower in oil coking plant

- Coking plant production capacity on the exclusion of the tower is also on the two: first, the coal tower; the two is coke bin;

- Q: What is the difference between coking plant and coke plant

- Never heard of coke plant, coking plant is the production of coke products, there are other chemical products, it is estimated that you said the coke plant is the purchase of other people's desire to sell second-hand coke traders.

- Q: What kind of coke is needed for smelting special steel

- 3) skeleton: smelting process in blast furnace is gas rise and decline occurred in the opposite charge of movement and interaction, the core permeability is the key operation of blast furnace. In the upper column, gas flow distribution of coke layer; in the middle of the column material, the coke from the skeleton effect, support has been melting the iron ore, the normal gas rise; in the lower column, high temperature in the solid massive existing coke and has become liquid hot metal and slag mixed together, become loose skeleton gas rising and falling iron and slag.

- Q: Listen to a lot of people say that steel is now coke is not true?

- Steelmaking is definitely not coke, but now most of the very mature iron making technology needs coke, the future direction of development of iron is not used or less coke

- Q: I see that there are metallurgical coke and coke on the Internet, what is the difference between them (I hope to be able to say in detail) and a level of two points, how is this going on?.. Where is the quality of coke in China? Hunan good coke plant which? Although the problem is a little bit more, I hope that insiders can give some useful information. Extremely grateful.

- Coke is a special and molten iron cupola coke. Coke is the main fuel cupola molten iron. Its role is to melt the burden and make the hot metal overheating, the support column to maintain good ventilation. Therefore, the foundry coke should have large blocks, low reactivity, porosity is small, with impact crushing strength, low ash and sulfur enough

- Q: Coke and coal is one thing

- Coke is bituminous coal under the condition of isolated air, heated to 950-1050 DEG C, after drying, pyrolysis, melting, bonding, solidification, shrinkage and other stages of the final coke, this process is called high temperature coking (high temperature carbonization).Coke is a deep processing of coal products.

- Q: I now do a good job in the coke network editor, I would like to know more about coke

- (2) reducing agent.The reduction of ore in blast furnace is accomplished by indirect reduction and direct reduction. The indirect reduction is about 400 degrees centigrade. The indirect reduction is rising gas CO reduction in ore, iron oxide from high iron gradually reduced low iron until the metal iron, while producing CO2:

- Q: Why in the blast furnace ironmaking with coke instead of charcoal why coke can produce heat to improve the heat of the furnace how to produceWhy in the blast furnace ironmaking with coke instead of charcoal why coke can produce heat to improve the heat of the furnace how to produce

- The role of coke in the blast furnace: 1 reducing agent 2 heating agent 3 skeleton role. Combined with the effect of coke in the blast furnace can know compared with coke instead of charcoal. The coke oven gas is produced high calorific value of fuel, and is an important raw material for organic synthesis industry.

Send your message to us

Metallurgical Coke of Coke Strength after Reactivity 65

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches