Metal rolling mill roll for Hot Strip Continuous Cold Continuous Universal Section Wire Rod CSP Mill

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Metal-rolling Mill Rolls

As a major manufacturing country, China accounts for 70% of the global production of rolls. In recent years, the trend in steel products in China has been: declining demand for construction steels such as rebar, wire rods, and narrow strips used in traditional construction, while there is a rapid increase in demand for plate and strip steels and section steels used in new infrastructure, new energy, and shipbuilding industries.

Suggested Materials across various rolling mills

| Rolling Mill | Mill Stand | Roll Material Selection | |

|---|---|---|---|

| Hot Strip Continuous Rolling Mill | Large Vertical Roll | Special Alloy Cast Steel, Adamite | |

| Small Vertical Roll | Adamite, High-Cr Iron | ||

| Roughing Work Roll | Special Alloy Cast Steel, Adamite, High-Cr Steel, Semi-HSS, High-Cr Iron | ||

| Finishing Work Roll | Early Stand | High-Cr Iron,HSS | |

| Late Stand | ICDP,HSS | ||

| Roughing & Finishing Stand Back-up Roll | Duplex Cast Steel | ||

| Temper Mill | Work Roll | High-Cr Iron | |

| Back-up Roll | ICDP, Duplex Cast Steel | ||

| CSPMill | Vertical Roll | Adamite, Special Alloy Cast Steel, High-Cr Iron | |

| Roughing Work Roll | Semi-HSS, High-Cr Steel | ||

| Finishing Rolling | Early Stand | HSS, High-Cr Iron | |

| Late Stand | ICDP,HSS | ||

| Roughing & Finishing Stand Back-up Roll | Duplex Cast Steel | ||

| Wire Rod & Bar Mill | Roughing Work Roll | Special Alloy Cast Steel, Alloy Spheres | |

| Finishing Rolling | Early Stand | ICDP | |

| Late Stand | ICDP,HSS, High-Boron High-Chromium Iron, Bainite | ||

| Medium & Heavy Plate Mill | Roughing Rolling | 2-Hi Work Roll | Special Alloy Cast Steel, Tool Steel |

| 4-Hi Work Roll | High-Cr Iron,ICDP | ||

| Finishing Work Roll | ICDP | ||

| Single-Stand Work Roll | High-Cr Iron,ICDP | ||

| Cold Continuous & Single-Stand Rolling Mill | Work Roll | Alloy Forged Steel | |

| Intermediate Roll | Alloy Forged Steel | ||

| Skin Pass Roll | Alloy Forged Steel | ||

| Large-Sized Universal Section Mill | Break-down Roll | Special Alloy Cast Steel, Alloyed Ductile Iron | |

| Horizontal Roll Ring | High Carbon Adamite (Duplex) | ||

| Vertical Roll Ring | High Carbon Adamite, High-Cr Iron | ||

| Edger | High Carbon Adamite | ||

Hot Strip and Plate Metal Mill Rolls

Hot plate/sheet mill rolls and strip/coil mill rolls are vital components in the steel manufacturing process, particularly in the production of flat steel products such as sheets, plates, strips, and coils. These rolls are used in rolling mills to shape and reduce the thickness of steel slabs and ingots into various forms such as sheets, plates, strips and coils.

1. ICDP Rolls – ‘Indefinite Chilled Double Poured’ Cast Iron Roll

| MATERIAL | CHEMISTRY | HARDNESS (HSD) | TENSILE STRENGTH (N/mm2) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NAME | CODE | C | Si | Mn | P | S | Cr | Ni | Mo | ROLL BARREL | ROLL NECK | |

| NiCrMo ICDP III | IC Ⅲ | 2.90-3.60 | 0.60-1.20 | 0.40-1.20 | ≤0.25 | ≤0.05 | 0.70-1.20 | 2.01-3.00 | 0.20-0.60 | 65-78 | 32-45 | ≥350 |

| NiCrMo ICDP IV | IC Ⅳ | 2.90-3.60 | 0.60-1.50 | 0.40-1.20 | ≤0.10 | ≤0.05 | 1.00-2.00 | 3.01-3.50 | 0.20-0.60 | 70-83 | 32-45 | ≥350 |

| 2.90-3.60 | 0.60-1.50 | 0.40-1.20 | ≤0.10 | ≤0.05 | 1.00-2.00 | 3.51-4.00 | 0.20-0.60 | |||||

| 2.90-3.60 | 0.60-1.50 | 0.40-1.20 | ≤0.10 | ≤0.05 | 1.00-2.00 | 4.01-4.80 | 0.20-1.00 | |||||

| Hi-NiCrMo ICDP V | ICDP Ⅴ | 2.90-3.60 | 0.60-1.50 | 0.40-1.20 | ≤0.10 | ≤0.05 | 1.00-2.00 | 4.01-4.80 | 0.20-2.00 | 77-85 | 32-45 | ≥350 |

| This table conforms to the Chinese National Standard GB/T 1504-2008. | ||||||||||||

2. High Chromium Cast Iron Roll

| MATERIAL | CHEMISTRY | HARDNESS (HSD) | TENSILE STRENGTH (N/mm2) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NAME | CODE | C | Si | Mn | P | S | Cr | Ni | Mo | V | ROLL BARREL | ROLL NECK | |

| High Chromium Cast Iron Centrifugal Composite | HCr Ⅰ | 2.30-3.30 | 0.30-1.00 | 0.50-1.20 | ≤0.10 | ≤0.05 | 12.00-15.00 | 0.70-1.70 | 0.70-1.50 | 0.00-0.60 | 60-75 | 32-45 | ≥350 |

| HCr Ⅱ | 2.30-3.30 | 0.30-1.00 | 0.50-1.20 | ≤0.10 | ≤0.05 | 15.01-18.00 | 0.70-1.70 | 0.70-1.50 | 0.00-0.60 | 65-80 | 32-45 | ≥350 | |

| HCr Ⅲ | 2.30-3.30 | 0.30-1.00 | 0.50-1.20 | ≤0.10 | ≤0.05 | 18.01-22.00 | 0.70-1.70 | 1.51-3.00 | 0.00-0.60 | 75-90 | 32-45 | ≥350 | |

| This table conforms to the Chinese National Standard GB/T 1504-2008. | |||||||||||||

3. High Chromium Cast Steel Roll

| MATERIAL | CHEMISTRY | HARDNESS (HSD) | TENSILE STRENGTH (N/mm2) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NAME | CODE | C | Si | Mn | P | S | Cr | Ni | Mo | ROLL BARREL | ROLL NECK | |

| High Chromium Steel | HCrs | 1.00-1.80 | 0.40-1.00 | 0.50-1.00 | ≤0.030 | ≤0.025 | 8.00-15.00 | 0.50-1.50 | 1.50-4.50 | 70-85 | 35-45 | ≥350 |

| This table conforms to the Chinese National Standard GB/T 1503-2008. | ||||||||||||

4. Chromium Steel Backup Rolls

| MATERIAL | CHEMISTRY | HARDNESS (HSD) | TENSILE STRENGTH (N/mm2) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NAME | CODE | C | Si | Mn | P | S | Cr | Ni | Mo | ROLL BARREL | ROLL NECK | |

| Chromium Steel | Cr3 | 0.30-0.50 | 0.3-0.6 | 0.4-1.0 | ≤0.035 | ≤0.025 | 2.50-3.50 | 0.60-1.50 | 0.30-0.60 | 55-65 | ≤55 | Centrifugal≥350, Static≥800 |

| Cr4 | 0.30-0.50 | 0.3-0.6 | 0.4-1.0 | ≤0.035 | ≤0.025 | 3.50-4.50 | 0.60-1.50 | 0.30-0.60 | 55-70 | |||

| Cr5 | 0.30-0.50 | 0.3-0.6 | 0.4-1.0 | ≤0.035 | ≤0.025 | 4.50-5.50 | 0.60-1.50 | 0.30-0.60 | 55-70 | |||

5. Adamite & Pearlite Vertical Rolls

| MATERIAL | CHEMISTRY | HARDNESS (HSD) | TENSILE STRENGTH (N/mm2) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NAME | CODE | C | Si | Mn | P | S | Cr | Ni | Mo | ROLL BARREL | ROLL NECK | |

| Adamite | AD140 | 1.30-1.50 | 0.30-0.60 | 0.70-1.40 | ≤0.035 | ≤0.030 | 0.80-1.60 | 0.20-0.60 | 38-55 | ≤48 | ≥590 | |

| AD140 Ⅰ | 1.30-1.50 | 0.30-0.60 | 0.70-1.10 | 0.80-1.20 | 0.50-1.20 | 0.20-0.60 | 35-50 | ≤45 | ||||

| AD160 | 1.50-1.70 | 0.30-0.60 | 0.70-1.10 | 0.80-1.20 | 0.20-0.60 | 40-50 | ≤50 | ≥490 | ||||

| AD160 Ⅰ | 1.50-1.70 | 0.30-0.60 | 0.80-1.30 | 0.80-2.00 | ≥0.20 | 0.20-0.60 | 40-60 | ≤50 | ||||

| AD180 | 1.70-1.90 | 0.30-0.80 | 0.60-1.10 | 0.80-1.50 | 0.50-2.00 | 0.20-0.60 | 40-60 | ≤50 | ||||

| AD190 | 1.80-2.00 | 0.30-0.80 | 0.60-1.20 | 1.50-3.50 | 1.00-2.00 | 0.20-0.60 | 55-65 | ≤50 | ||||

| AD200 | 1.90-2.10 | 0.30-0.80 | 0.80-1.20 | 0.60-2.00 | 0.60-2.50 | 0.20-0.80 | 50-65 | ≤50 | ||||

| The above table conforms to the Chinese National Standard GB/T 1503-2008, and the following table conforms to the Chinese National Standard GB/T1504-2008. | ||||||||||||

| Pearlite | SGP Ⅰ | 2.90-3.60 | 1.40-2.20 | 0.40-1.00 | ≤0.15 | ≤0.30 | 0.10-0.60 | 1.50-2.00 | 0.20-0.80 | 45-55 | 35-55 | ≥450 |

| SGP Ⅱ | 2.90-3.60 | 1.20-2.00 | 0.40-1.00 | 0.20-1.00 | 2.01-2.50 | 0.20-0.80 | 55-65 | |||||

| SGP Ⅲ | 2.90-3.60 | 1.00-2.00 | 0.40-1.00 | 0.20-1.20 | 2.51-3.00 | 0.20-0.80 | 62-72 | |||||

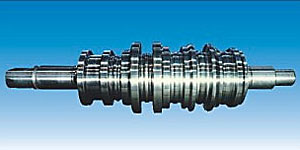

Section Rolling Mill Rolls

Section Mill Rolls play an essential role in the world of steel manufacturing. With the extensive range of rolls, including Alloy Steel Rolls and Pearlitic Ductile Iron Rolls, we deliver precision and durability that meet the rigorous demands of the industry. Our High Carbon Adamite Roller Ring is engineered to withstand the harshest conditions, ensuring long-lasting performance. Whether you're shaping beams, channels, angles, or other section steel products, our rolls are designed to enhance your mill's efficiency and product quality.

1. Alloy Steel, Adamite & Pearlite Ductile Iron Roll

| MATERIAL | CHEMISTRY | HARDNESS (HSD) | TENSILE STRENGTH (N/mm2) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NAME | CODE | C | Si | Mn | P | S | Cr | Ni | Mo | ROLL BARREL | ROLL NECK | |

| Alloy Steel | AS60 | 0.55-0.65 | 0.20-0.45 | 0.90-1.20 | ≤0.035 | ≤0.030 | 0.80-1.20 | 0.20-0.45 | 35-50 | ≤45 | ≥650 | |

| AS65 Ⅰ | 0.60-0.70 | 0.20-0.60 | 0.50-0.80 | 0.80-1.20 | 0.20-0.50 | 0.20-0.60 | 35-45 | ≤45 | ≥650 | |||

| AS70 | 0.65-0.75 | 0.20-0.45 | 0.90-1.20 | 32-42 | ≤42 | ≥600 | ||||||

| AS70 Ⅰ | 0.65-0.75 | 0.20-0.45 | 1.40-1.80 | 35-45 | ≤45 | ≥600 | ||||||

| AS70 Ⅱ | 0.65-0.75 | 0.20-0.45 | 1.40-1.80 | 0.20-0.45 | 35-45 | ≤45 | ≥680 | |||||

| AS75 | 0.70-0.80 | 0.20-0.45 | 0.60-0.90 | 0.75-1.00 | 0.20-0.45 | 35-50 | ≤45 | ≥680 | ||||

| AS75 Ⅰ | 0.70-0.80 | 0.20-0.70 | 0.70-1.10 | 0.80-1.50 | ≥0.20 | 0.20-0.60 | 35-50 | ≤45 | ≥700 | |||

| Adamite | AD140 | 1.30-1.50 | 0.30-0.60 | 0.70-1.40 | ≤0.035 | ≤0.030 | 0.80-1.60 | 0.20-0.60 | 38-55 | ≤48 | ≥590 | |

| AD140 Ⅰ | 1.30-1.50 | 0.30-0.60 | 0.70-1.10 | 0.80-1.20 | 0.50-1.20 | 0.20-0.60 | 35-50 | ≤45 | ||||

| AD160 | 1.50-1.70 | 0.30-0.60 | 0.70-1.10 | 0.80-1.20 | 0.20-0.60 | 40-50 | ≤50 | ≥490 | ||||

| AD160 Ⅰ | 1.50-1.70 | 0.30-0.60 | 0.80-1.30 | 0.80-2.00 | ≥0.20 | 0.20-0.60 | 40-60 | ≤50 | ||||

| AD180 | 1.70-1.90 | 0.30-0.80 | 0.60-1.10 | 0.80-1.50 | 0.50-2.00 | 0.20-0.60 | 40-60 | ≤50 | ||||

| AD190 | 1.80-2.00 | 0.30-0.80 | 0.60-1.20 | 1.50-3.50 | 1.00-2.00 | 0.20-0.60 | 55-65 | ≤50 | ||||

| AD200 | 1.90-2.10 | 0.30-0.80 | 0.80-1.20 | 0.60-2.00 | 0.60-2.50 | 0.20-0.80 | 50-65 | ≤50 | ||||

| The above table conforms to the Chinese National Standard GB/T 1503-2008, and the following table conforms to the Chinese National Standard GB/T 1504-2008. | ||||||||||||

| Pearlite | SGP Ⅰ | 2.90-3.60 | 1.40-2.20 | 0.40-1.00 | ≤0.15 | ≤0.30 | 0.10-0.60 | 1.50-2.00 | 0.20-0.80 | 45-55 | 35-55 | ≥450 |

| SGP Ⅱ | 2.90-3.60 | 1.20-2.00 | 0.40-1.00 | 0.20-1.00 | 2.01-2.50 | 0.20-0.80 | 55-65 | |||||

| SGP Ⅲ | 2.90-3.60 | 1.00-2.00 | 0.40-1.00 | 0.20-1.20 | 2.51-3.00 | 0.20-0.80 | 62-72 | |||||

2. High Carbon Adamite Roll Ring

| MATERIAL | CHEMISTRY | HARDNESS (HSD) | TENSILE STRENGTH (N/mm2) | HARDNESS DROP (HSD) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NAME | CODE | C | Si | Mn | P | S | Cr | Ni | Mo | ROLL RING BARREL | INNER LAYER | ||

| Adamite | AD160 | 1.50-1.70 | 0.30-0.60 | 0.70-1.10 | ≤0.035 | ≤0.030 | 0.80-1.20 | 0.20-0.60 | 50-65 | 35-45 | ≥600 | ≤5 | |

| AD160 Ⅰ | 1.50-1.70 | 0.30-0.60 | 0.80-1.30 | 0.80-2.00 | ≥0.20 | 0.20-0.60 | 50-65 | ||||||

| AD180 | 1.70-1.90 | 0.30-0.80 | 0.60-1.10 | 0.80-1.50 | 0.50-2.00 | 0.20-0.60 | 55-65 | ||||||

| AD190 | 1.80-2.00 | 0.30-0.80 | 0.60-1.20 | 1.50-3.50 | 1.00-2.00 | 0.20-0.60 | 55-65 | ||||||

| AD200 | 1.90-2.10 | 0.30-0.80 | 0.80-1.20 | 0.60-2.00 | 0.60-2.50 | 0.20-0.80 | 55-65 | ||||||

Bar & Wire Mill Rolls

Bar, rod, and wire mill rolls play a crucial role in the steel manufacturing process. These rolls are an essential component of rolling mills designed to shape and reduce the cross-sectional area of steel billets or ingots into long, slender products like bars, rods, and wires. They serve as vital components in construction for concrete reinforcement, in manufacturing for producing various fasteners such as bolts, nails, and screws, and in the automotive sector for crafting components like springs and spokes.

1. Ductile Iron Roll

| MATERIAL | CHEMISTRY | HARDNESS (HSD) | CORE TENSILE STRENGTH (N/mm2) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NAME | CODE | C | Si | Mn | P | S | Cr | Ni | Mo | ROLL BARREL | ROLL NECK | |

| NiCrMo ICDP Ⅱ | IC Ⅱ | 2.90-3.60 | 0.80-2.50 | 0.40-1.20 | ≤0.20 | ≤0.03 | 0.30-1.20 | 1.01-2.00 | 0.20-0.80 | 50-70 | 35-55 | ≥350 |

| Pearlite Ⅱ | SGP Ⅱ | 2.90-3.60 | 0.80-2.50 | 0.40-1.20 | ≤0.20 | ≤0.03 | 0.20-1.20 | 2.01-2.50 | 0.20-0.80 | 55-70 | 35-55 | ≥350 |

| Pearlite Ⅲ | SGP Ⅲ | 2.90-3.60 | 1.00-2.00 | 0.40-1.00 | ≤0.15 | ≤0.03 | 0.20-1.20 | 2.51-3.00 | 0.20-0.80 | 63-73 | 35-55 | ≥350 |

2. Bainite Nodular Cast Iron Roll

| MATERIAL | CHEMISTRY | HARDNESS (HSD) | TENSILE STRENGTH (N/mm2) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NAME | CODE | C | Si | Mn | P | S | Cr | Ni | Mo | ROLL BARREL | ROLL NECK | |

| Bainite Centrifugal Composite Ⅰ | SGA Ⅰ | 2.90-3.60 | 1.20-2.20 | 0.20-0.80 | ≤0.10 | ≤0.03 | 0.20-1.00 | 3.01-3.50 | 0.50-1.00 | 55-78 | 32-45 | ≥350 |

| Bainite Centrifugal Composite Ⅱ | SGA Ⅱ | 2.90-3.60 | 1.00-2.00 | 0.20-0.80 | ≤0.10 | ≤0.03 | 0.30-1.50 | 3.51-4.50 | 0.50-1.00 | 60-80 | 32-45 | ≥350 |

| The above table conforms to the Chinese National Standard GB/T 1504-2008. | ||||||||||||

3. High Speed Steel, Semi-HSS Roll

| MATERIAL | CHEMISTRY | HARDNESS (HSD) | TENSILE STRENGTH (N/mm2) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NAME | CODE | C | Si | Mn | P | S | Cr | Ni | Mo | V | W | ROLL BARREL | ROLL NECK | |

| HSS | HSS | 1.50-2.20 | 0.30-1.00 | 0.40-1.20 | ≤0.030 | ≤0.025 | 3.00-8.00 | 0.00-1.50 | 2.00-8.00 | 2.00-9.00 | 0.00-8.00 | 75-95 | 30-45 | ≥350 |

| SEMI-HSS | S-HSS | 0.60-1.20 | 0.80-1.50 | 0.50-1.00 | 3.00-9.00 | 0.20-1.20 | 2.00-5.00 | 0.40-3.00 | 0.00-8.00 | 75-98 | 30-45 | ≥350 | ||

| The above table conforms to the Chinese National Standard GB/T 1503-2008. | ||||||||||||||

4. Modified Semi-HSS Roll

| CHEMISTRY PROPERTY | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Ni | Mo | V | B | W | Nb |

| 0.45-3.30 | 0.15-1.50 | 0.15-1.50 | 4.00-27.00 | 1.00-3.50 | 0.50-2.00 | 0.20-5.00 | 0.20-1.50 | 0.20-5.00 | 0.20-3.00 |

| MECHANICAL PROPERTY | |||||||||

| TENSILE STRENGTH (N/mm2) | HARDNESS (HSD) | IMPACT TOUGHNESS (J/cm2) | |||||||

| 700-900 | 70-85 | 60-15 | |||||||

| ROLL PASS STEEL REFERENCE | |||||||||

| Roll Mill Finishing Stand | Single Channel Roll Pass Steel Quantity (ton) | Cutting and Pre-cutting Stand | Single Channel Roll Pass Steel Quantity (ton) | ||||||

| φ12 Finished Product | 200-300 | φ12 Three Segmentation | 1,200-3,500 | ||||||

| φ14 Finished Product | 250-400 | φ14 Three Segmentation | 1,400-3,500 | ||||||

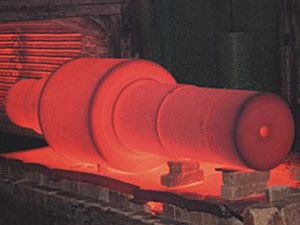

Casting Equipment

Our modern casting equipment is designed to produce high-quality rolling mill rolls with precise and durable results. At our centrifugal roll pouring site, we utilize advanced techniques to ensure uniform material distribution. Our 10-ton medium-frequency furnace provides consistent melting and casting processes, while our 10-ton centrifuge enhances the structural integrity of our rolls.

Centrifugal casting pouring site

10-ton medium frequency furnace

10-ton centrifuge

Rolling roll integral casting site.

Heat Treatment Equipment

Integral or centrifugal cast rolls are heat-treated to enhance strength, relieve stresses, refine microstructure, increase wear resistance, improve thermal stability, and reduce porosity.

High temp flatbed resistance furnaces for heat treatment processing

Cast rolls taken out of high tempfurnace

Cast rolls taken out of high temp furnace

Machining Equipment

Our modern machining equipment ensures precision and efficiency in the manufacturing of rolling mill rolls. We utilize a variety of advanced tools, including CNC machine tools for accurate shaping, horizontal lathes for versatile turning operations, and gantry milling machines for large-scale milling tasks. Our grinding machines provide the finest finishes, while our roll end CNC letter engraving machines ensure detailed customizations. This comprehensive range of equipment allows us to meet the diverse needs of our clients with the highest quality standards

Inside the machining workshop scene

CNC machine tool CK84125D

Horizontal lathe CW61160L

Horizontal lathe CW61160C

Gantry milling machine X2016-6M

Grinding machine M1363

Roll end letter engraving machine

Testing Equipment

Our modern testing equipment ensures the highest standards of quality and precision in every roll we produce. We utilize advanced tools including a spectrometer for accurate chemical analysis, a metallographic microscope for detailed material examination, comprehensive dimensional inspection tools, and ultrasonic flaw detectors for identifying internal defects. Additionally, our on-site roll metallography testing allows for thorough and immediate assessment, guaranteeing optimal performance and reliability in all our products.

Spectrometer testing lab

Metallographic microscope lab

Precise dimensional inspection

Ultrasonic flaw detector

On-site hardness testing

*****Last Updated 20240826*****

- Q: How to strengthen the shock resistance of powder metallurgy metal parts?

- Product design, R angle must be greater than 1mm, in principle, the bigger the better.

- Q: Process flow of powder metallurgy parts plating

- And in the subsequent storage and use process, the coating and substrate will be corroded.

- Q: What kind of imported metallurgical machinery parts do steel mills need to rely on?

- I know some imported electromagnetic stirring, casting, peeling machine, pneumatic sample delivery system, mold advanced, advanced ladle turntable.

- Q: Why are powder metallurgy parts generally small?

- The advantages of powder metallurgy parts can be exploited more in small parts.

- Q: How can make powder metallurgy machinery fittings have hardness, toughness?

- Join an alloying element, such as nickel, molybdenum, etc,or increase the heat treatment process: carbonitriding.

- Q: What is the manufacture of powder metallurgy machinery parts?

- Powder metallurgy is similar to the production of ceramics, all belong to powder sintering technology. Therefore, a series of powder metallurgy new technology can also be used for the preparation of ceramic materials. Because of the advantages of powder metallurgy technology, it has become the key to solve the problem of new materials and plays an important role in the development of new materials.

- Q: Why does the aspect ratio of powder metallurgy machine parts need to be controlled?

- The traditional unidirectional pressing leads to uneven density distribution, which leads to the limited ratio of height to diameter, and to friction compaction.

- Q: What are the types of powder metallurgy machinery parts?

- There are two kinds of powder metallurgy parts forming: press forming and injection molding.

- Q: What kind of high temperature anticorrosive coating is used for metallurgical high temperature parts?

- The alternating coating of hot and cold can not crack and fall off. The coating is dense, acid resistant and alkali resistant, and can withstand high temperature 1300 DEG C. FDA certification, non-toxic environmental protection.

- Q: What is the cost of the powder metallurgy machine parts?

- The cost of raw materials, auxiliary materials, generally by the artificial and manufacturing cost etc.. Powder metallurgy. The material must be lower than the casting parts. I think it is equivalent to adding a casting process from powder metallurgy to an ordinary casting part.

Send your message to us

Metal rolling mill roll for Hot Strip Continuous Cold Continuous Universal Section Wire Rod CSP Mill

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches