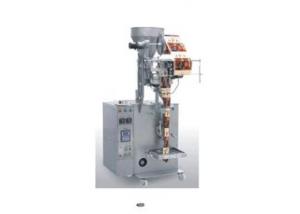

Mechanical Chuck Three-position Automatic Packing Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mechanical Chuck Three-position Automatic Packing Machine

1. Product Description:

This machine is suitable for packaging powder, granule, particle, block type, bar type or irregular articles. For instance: puffed food, candy, grain, bean, milk, seasoning, oatmeal, tea, toy, screw, camphor ball and drier, soup spice ,cereal, desiccant.

2. Product Features:

A,with date printer

B,adjustabel bag size and weight

C,low noise

D,with cursor position sensor

3. Product Parameters:

Model | JZ-5K-SB(RB) | JZ-8K-SB(RB) | JZ-10K-SB(RB) | JZ-12K-SB(RB) |

High frequency power | 5KW | 8KW | 10KW | 12KW |

Oscillation tube | 7T85RB | 7T69RB | 3069RB | E3130RB |

Biggest pressure | 470KG | 700KG | Customization | |

Gap of electrodes | 230mm | 210mm | ||

Press stroke | 200mm | |||

Size of upper plate | 200*350mm | 400*600mm | Customization | |

Size of lower plate | 400*600mm | 600*800mm | ||

Supply voltage | 220V/380V(50/60HZ) | 380V/60MHz | ||

Frequency | 27.12MHz or 40.68MHz | |||

Power input | 8.5KVA | 15KVA | 20KVA | |

Rectifier | Silicon diode | |||

Temp range | 0~200°C | |||

Station | Two work station push table or round turn table | |||

Operation mode | Full pneumatic | |||

Welding time | 0~10s adjustable | |||

Physical size | 1.1*2.0*1.8m | 1.1*2.7*1.85 | Customization | |

4. FAQ:

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

Q3: What kind of after-sevices do you provide?

A: If it is not big problem, we can solve it by emails, phone etc. If it can’t work, our engineers can go to overseas to install and adjust the machine and solve the problems.

5. Product Pictures:

- Q: Vacuum packing machine for cooked food: can whole chicken, whole goose and whole duck be packed?

- Well, yesBut the vacuum packaging machines used for different product sizes are different

- Q: What are the main plastic forming processes?

- Plastic processing is a complex process, generally divided into the following processing methods:In order to improve the quality of the product and improve the molding efficiency, the pre pressing is used to press the powder or fibrous molding material into a certain shape in advance.Preheating, in order to improve the processing performance and shorten the molding cycle of molding plastics, the molding plastics are heated prior to molding.Molding in the mold to add the required amount of plastic, closed mold and exhaust, at the mold temperature and pressure to maintain a period of time, and then release mold cleaning operations

- Q: What are the packing machines?

- Heat shrink packaging machine, mask packaging machine, pillow type packaging machine, food packaging machine, I suggest you can go to see

- Q: What kind of reducer is commonly used in packaging machinery?

- Generally speaking, gear reducer, planetary gear reducer, and the most common one, these equipment power is relatively small, and some need to take the brakes of the motor reducer

- Q: What are the main functions of packaging machinery and equipment?

- Packaging machinery can be realized in the packaging process, including filling and wrapping,

- Q: What is the name of the paper used in packing machine parts and yellow?

- Rust preventive action, commonly used for steel vapor rust preventive paper, but also for a variety of metals.

- Q: Food packaging process is not standardized, there is no responsibility?! For example, after the production of candy, because there is no corresponding packaging equipment, the need for artificial packaging

- Yes, automatic packing machine. I'm an employee of the automatic packaging machinery company.

- Q: What does that mean when the composite material is pressed and molded? What are pressing forming? What are the characteristics of press molding equipment? Its development

- Different conceptsCompression molding refers to hot forming: mainly for thermoplastic materials (sheet), the use of hot forming machine, Blister molding, I think it should also be considered as a branch of hot stamping, vacuum or high-pressure gas will be used to assist. Hot pressing sheet forming a relatively small depth, relatively simple structure, low precision products, such as packaging materials, plastic pallets, plates in the dishes and so on. There are also forming plate pressing molding (lamination)

- Q: Food, equipment, tools, containers, packaging materials, etc. shall comply with food safety standards or requirements

- Hygienic standard for polyethylene terephthalate resin for GB 13114 food containers and packaging materialsGB, 13113-1991. Hygienic standard for polyethylene terephthalate molded articles for food containers and packaging materials

- Q: Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- Ha ha, as you say, TV factories are closed down, every household has a TV, but every day there will be a lot of people buy tv.

Send your message to us

Mechanical Chuck Three-position Automatic Packing Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords