MC Hot Rolled Square Steel Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20-35 watt

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 0.45 - 2.5 mm | Section Shape: | Square | Place of Origin: | Hebei China (Mainland) |

| Secondary Or Not: | Non-secondary | Application: | furniture pipe. fence tube,structure pipe etc.,handle railings.fence tube,shelves, furniture, threading tube | Technique: | Cold Rolled |

| Certification: | 50x50mm square pipe | Surface Treatment: | pre-galvanzied,black,pre-galvanized,black annealed | Alloy Or Not: | Non-alloy |

| Material: | Q195,Q215,Q235 | Technology: | Colled rolled | Wall thickness: | 0.45mm-2.5mm |

| Length: | 4.5m~7m | Lenght tolerance: | +/-20mm | OD tolerance: | +/-0.5mm |

| Thickness tolerance: | +/-0.03mm | Grade: | Q235,Q195,Q215,Q195-Q345 | Standard: | GB/T3901,GB,GB/T 3091-2008 |

Packaging & Delivery

| Packaging Detail: | in bulk, in small bundle or as customer's request |

| Delivery Detail: | about 10 days after receiving customer's deposit |

Specifications

square steel pipe :

Material: Q195,Q215,Q235

Surface: pre-galvanized,black

Wall thickness: 0.45mm-2.5

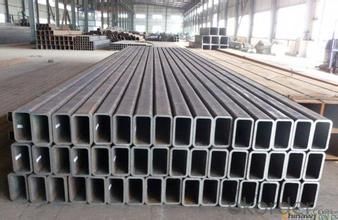

MC Steel Pipe Image

FAQ of MC Steel Pipe

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

- Q: What are the different types of supports used for aboveground steel pipes?

- There are several types of supports used for aboveground steel pipes, including pipe hangers, pipe shoes, pipe clamps, and pipe rollers. These supports are designed to provide stability, prevent sagging, and distribute the weight of the pipe evenly, ensuring the structural integrity of the system.

- Q: What are the different end finishes for steel pipes?

- There are several different end finishes for steel pipes, depending on their intended use and the specific requirements of the application. Some of the most common end finishes for steel pipes include: 1. Plain End: This is the simplest and most common type of end finish, where the pipe is cut square at both ends without any additional treatment or threading. Plain end pipes are typically used for low-pressure applications or when the pipe will be connected using welding methods. 2. Beveled End: A beveled end finish involves cutting the pipe at an angle, usually 30 or 37.5 degrees, to facilitate easier welding and create a stronger joint. Beveled end pipes are commonly used for butt-welding applications, where two pipes are joined together by aligning the beveled ends and welding them. 3. Threaded End: In this end finish, the pipe is threaded at both ends to allow for easy connection with threaded fittings or couplings. Threaded end pipes are commonly used in plumbing and gas distribution systems, as well as for applications that require frequent disassembly and reassembly. 4. Coupled End: Coupled end finishes involve the installation of couplings or connectors at each end of the pipe. This allows for quick and easy connection of pipes without the need for additional threading or welding. Coupled end pipes are often used in oil and gas pipelines or in applications where rapid installation is required. 5. Grooved End: A grooved end finish involves cutting grooves into the pipe's ends and using mechanical couplings or fittings to join the pipes together. This type of end finish is commonly used in fire protection systems, as well as for large-diameter pipes that require quick and efficient assembly. 6. Flanged End: Flanged end finishes involve attaching flanges to the pipe ends, which can be bolted together to create a secure and leak-proof connection. Flanged end pipes are commonly used in applications that require easy disassembly and reassembly, such as in chemical plants or refineries. It is important to note that the choice of end finish for a steel pipe depends on factors such as the application, the required joint strength, the type of connection method, and the compatibility with other system components. Consulting with a professional or referring to industry standards is recommended to ensure the correct end finish is selected for a specific application.

- Q: How are steel pipes used in sewage treatment plants?

- Steel pipes are used in sewage treatment plants to transport and distribute wastewater throughout the facility. They are crucial in carrying raw sewage from the intake point to various treatment processes such as sedimentation tanks, filtration units, and aerobic/anaerobic digesters. Additionally, steel pipes may be utilized for pumping treated or partially treated wastewater to outfall locations or for reuse purposes. The durability and corrosion resistance of steel make it an ideal choice for handling the harsh and corrosive nature of sewage, ensuring long-lasting and efficient operation of the treatment plant.

- Q: What are the quality control measures for steel pipe manufacturing?

- Quality control measures for steel pipe manufacturing typically include: 1. Raw material inspection: Ensuring that the steel used for manufacturing pipes meets the required specifications and standards. 2. Dimensional checks: Verifying the outer diameter, wall thickness, and length of the pipes to ensure they meet the specified tolerances. 3. Visual inspection: Examining the surface of the pipes for any defects, such as cracks, pits, or corrosion, that could impact their quality or performance. 4. Mechanical testing: Conducting tests, such as tensile strength, yield strength, and hardness tests, to assess the mechanical properties of the pipes. 5. Non-destructive testing (NDT): Employing techniques like ultrasonic testing, magnetic particle inspection, or radiography to detect internal defects or flaws in the pipes without damaging them. 6. Welding inspection: Assessing the quality and integrity of welds used in joining pipe sections together, ensuring they meet the required standards. 7. Coating inspection: Checking the applied protective coatings for uniformity, adhesion, and resistance to corrosion or other environmental factors. 8. Pressure testing: Subjecting a sample of pipes to a hydraulic or pneumatic pressure test to verify their ability to withstand the intended operating conditions without leakage or failure. 9. Packaging and labeling: Ensuring proper packaging and labeling of the pipes, including identification of grade, size, and other relevant details, to facilitate easy identification and handling. 10. Documentation: Maintaining comprehensive records of all quality control activities, including test results, inspection reports, and certifications, for traceability and quality assurance purposes.

- Q: Can steel pipes be used for transportation of hazardous materials?

- The transportation of hazardous materials can indeed utilize steel pipes. Steel is renowned for its robustness, longevity, and resistance to rust, which renders it suitable for the management and conveyance of various perilous substances. This encompasses combustible liquids, noxious chemicals, and other hazardous materials. Steel pipes, employed for the transportation of hazardous materials, are frequently custom-designed and fabricated to comply with strict safety regulations and industry standards. They are typically forged from top-notch steel alloys and subjected to stringent tests to guarantee their integrity and resistance to leaks or ruptures. Additionally, steel pipes can be manufactured with supplementary protective coatings or linings to furnish an extra layer of security and avert any potential reactions between the hazardous substance and the steel. These coatings can also aid in reducing the risk of corrosion and prolonging the lifespan of the pipes. In summary, steel pipes have an established record in the transportation of hazardous materials due to their inherent strength, durability, and ability to withstand the challenging conditions frequently encountered during transportation. Nonetheless, it is imperative to adhere to proper protocols for handling, storage, and transportation to ensure the safety of both the transported materials and the individuals involved in the process.

- Q: What is the impact of temperature on steel pipes?

- The impact of temperature on steel pipes is significant and can have both positive and negative effects. At high temperatures, steel pipes can experience thermal expansion, causing them to expand and potentially leading to distortion or buckling. This expansion can also affect the joints and connections, potentially causing leaks or failures. Therefore, it is crucial to consider the coefficient of thermal expansion when designing and installing steel pipes in high-temperature environments. On the other hand, steel pipes typically have excellent thermal conductivity, allowing them to withstand high temperatures without significant degradation. This makes them suitable for applications where heat transfer is a primary concern, such as in industrial processes or heating systems. Extreme cold temperatures can have detrimental effects on steel pipes as well. In freezing conditions, water or other fluids inside the pipes can expand and lead to cracks or bursts. This can cause leaks, loss of fluid, and potential damage to surrounding structures. Therefore, appropriate insulation and preventive measures need to be taken to ensure the integrity of steel pipes in cold environments. Additionally, temperature variations can also affect the mechanical properties of steel, such as its tensile strength and toughness. For instance, exposure to elevated temperatures over an extended period can lead to a phenomenon known as thermal degradation, where the steel's strength decreases, making it more prone to deformation or failure. In conclusion, the impact of temperature on steel pipes is significant and can influence their structural integrity, thermal performance, and mechanical properties. Proper design, insulation, and maintenance are essential to ensure the safe and efficient operation of steel pipes in various temperature conditions.

- Q: Are steel pipes more expensive than other types of pipes?

- Steel pipes can be more expensive than other types of pipes, but this can vary depending on various factors such as the size, grade, and specific application requirements.

- Q: How do you prevent corrosion in steel pipes?

- One effective way to prevent corrosion in steel pipes is by applying a protective coating, such as paint or epoxy, to the surface of the pipes. This barrier creates a physical barrier between the pipe and the surrounding environment, preventing moisture and corrosive agents from coming into direct contact with the steel. Additionally, regular inspection and maintenance of the pipes, including cleaning and repairing any damaged coating, can help identify and address potential issues before they lead to corrosion.

- Q: How are steel pipes used in the marine industry?

- Steel pipes are commonly used in the marine industry for various applications such as transportation of fluids, structural support, and offshore drilling. They are used for the construction of ships, offshore platforms, and pipelines, as they possess high durability, strength, and corrosion resistance. Additionally, steel pipes are used for cooling systems, ballast transfer, and other critical functions required in marine engineering.

- Q: What are the common maintenance practices for steel pipes?

- Steel pipes require regular inspections, cleaning, and corrosion prevention as part of their maintenance. It is crucial to conduct inspections frequently to detect any signs of damage or wear. These inspections can involve visual assessments and non-destructive testing methods like ultrasonic or magnetic particle inspection. Scheduling inspections ensures early detection of issues, allowing for prompt resolution. Cleaning is also a vital maintenance practice for steel pipes. It involves the removal of dirt, debris, and scale that may accumulate on both the inside and outside of the pipes. Regular cleaning prevents blockages, enhances flow efficiency, and reduces the risk of corrosion. Corrosion prevention plays a significant role in maintaining steel pipes. Different methods, such as applying protective coatings, utilizing cathodic protection systems, or implementing corrosion inhibitors, can be employed to safeguard the pipes. These measures extend the pipes' lifespan and preserve their structural integrity over time. Additional maintenance practices may include repairing or replacing damaged sections of the pipes, maintaining proper insulation to prevent heat loss or gain, and monitoring the pipes for any signs of leakage or pressure drops. In summary, regular inspections, cleaning, and corrosion prevention are vital maintenance practices for steel pipes. Implementing these practices prolongs the pipes' lifespan and allows for the identification and resolution of potential issues before they cause significant damage or disruptions.

Send your message to us

MC Hot Rolled Square Steel Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20-35 watt

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords