Magnesium Alloy Ingot with Shortest Delivery Time

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Magnesium Alloy Ingot with Shortest Delivery Time

Magnesium Alloy Ingot for Vibration Platform with a small specific gravity, high intensity , high wear-resisting performance, has some of the corrosion resistance and resistance to radiation performance, good chemical stability against the alkali, mineral , excellent weldability and workability.

Advantage of Magnesium Alloy Ingot with Shortest Delivery Time

Compared with aluminum and aluminum alloy, the Magnesium Alloy Ingot can take more impact load ability and has so many other superior performance. Magnesium alloy has the good electromagnetic shielding ability, so it is applied in the aerospace, automotive, chemical, electronic and other military industrial and civil industry;

Production Process of Magnesium Alloy Ingot with Shortest Delivery Time

Adopt the hot rolling process, ensure the product good mechanical properties, refinement of grain structure, high strength and great ductility, etc.

Application of Magnesium Alloy Ingot with Shortest Delivery Time

vibration platform, the aerospace industry, denfense industry , automobile industry ,etc.

Size of Magnesium Alloy Ingot with Shortest Delivery Time

5kg、6kg、7.5kg、8kg、12kg and AZ91D、AZ31B\AM50\AM60

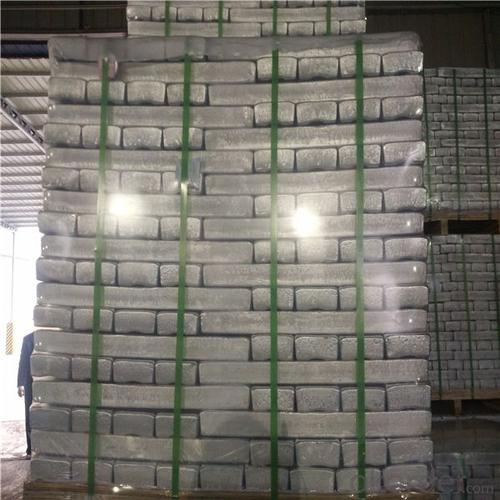

Photo of Magnesium Alloy Ingot with Shortest Delivery Time

Chemical Composition of Magnesium Alloy Ingot with Shortest Delivery Time:

Designation | 1 Al | 8 Be | 7 Cu | 5 Fe | 3 Mn | 6 Ni | 4 Si | 2 Zn |

AZ91D | 8.5-9.5 | 0.0005-0.0015 | 0.0025 | 0.004 | 0.17-0.40 | 0.001 | 0.08max | 0.45-0.09 |

AM60B | 5.6-6.4 | 0.0005-0.0015 | 0.008 | 0.004 | 0.26-0.50 | 0.001 | 0.08max | 0.20max |

AM50A | 4.5-5.3 | 0.0005-0.0015 | 0.008 | 0.004 | 0.28-0.50 | 0.001 | 0.08max | 0.20max |

AZ63A | 5.5-6.5 | - | 0.2 | 0.00035 | 0.15-0.35 | 0.01 | 0.2 | 0.27-3.3 |

AZ91A | 8.5-9.5 | - | 0.08 | - | 0.15-0.40 | 0.01 | 0.20max | 0.45-0.9 |

AZ91B | 8.5-9.5 | - | 0.25 | - | 0.15-0.40 | 0.01 | 0.20max | 0.45-0.9 |

AZ91C | 8.3-9.2 | - | 0.08 | - | 0.15-0.35 | 0.01 | 0.2 | 0.45-0.9 |

AZ91E | 8.3-9.2 | - | 0.015 | 0.005 | 0.17-0.50 | 0.001 | 0.2 | 0.45-0.9 |

FAQ of Magnesium Alloy Ingot with Shortest Delivery Time:

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:Can U accept the detective of the third-party verification company ?

A:YES! We can accept the detective from any third-party verification company including the SGS, BV and so on.

- Q: Causes of high manganese content in magnesium ingot

- Magnesium in the air in the combustion reaction of oxygen, magnesium and Magnesium Oxide in the air, and the quality of the quality of the resulting Magnesium Oxide equal in response to magnesium and oxygen quality, so the quality of the product than the quality of the original magnesium increases.

- Q: What is the black powder on the surface of magnesium ingot AM50A?

- These are commonly used in the die casting magnesium alloy brand.

- Q: What are the surface defects of magnesium alloy rolling?

- Because magnesium alloys are made of magnesium ingots, while magnesium ingots contain other elementsTherefore, magnesium alloys are generally used in die castingAluminum alloy is rolled only

- Q: What harm does magnesium alloy have to human body?

- The main element of magnesium aluminum alloy and AZ91D is magnesium. As long as it is not dust (flammable or explosive), direct contact with magnesium ingot is harmless

- Q: What are the generally feasible surface treatment methods for magnesium alloy die castings?

- 1. chromate passivation method, which is the most widely used and the most important method in industry. The so-called chromate passivation solution is metal with chromic acid, chromate or dichromate as a major component of the film on the metal surface to form a compound composed of trivalent chromium and hexavalent chromium and six metal itself, this film has protective passivation metal corrosion inhibition for. The specific passivation process is to dip the magnesium ingot which is intended to be passivated into the passivation solution. At this time, the surface metal is oxidized by the solution, forming metal ions into the solution. Since the solution is acidic, the following reactions occur: 3Mg ten, 2HN03 = 4Mg0, ten H20, ten 2N02. anodic oxidation is a surface treatment method to increase the thickness of base metal oxide film by electrolytic reaction and to improve the film properties. The film has excellent corrosion resistance and abrasion resistance.

- Q: Why the cost of ferrosilicon production will lead to a rebound in the price of magnesium ingot?

- 75# ferrosilicon in pidgeonmagnesiumprocess often used in high temperature smelting process of magnesium metal, will be replaced from CaO.MgO mg, each ton of magnesium will consume 1.2 tons of ferrosilicon, plays a big role in magnesium production.

- Q: The industrial application of magnesium and the main title and technical difficulty of producing magnesium products with magnesium chloride as raw material

- The chemical property of magnesium is active, in the metallurgical industry by using, steel and non-ferrous metal casting, with magnesium as desulfurization agent, cleaning agent, as reducing agent in the production of rare metal. In the chemical industry, magnesium can be used as a dehydrating agent of organic compounds or directly with organic compounds and preparation of magnesium powder. In recent years, in the use of magnesium powder spray, coating, anticorrosion industry is more and more big, the amount of silicon and polysilicon and powder metallurgy die casting is also great.

- Q: What are the differences between aluminium magnesium alloy, aluminum alloy and plastic steel?

- An alloy based on aluminum. The main alloying elements are copper, silicon, magnesium, zinc and manganese. The minor alloying elements are nickel, iron, titanium, chromium, lithium and so onAluminum alloy low density, but relatively high strength, close to or higher quality steel, plastic good, can be processed into various profiles, with excellent conductivity, thermal conductivity and corrosion resistance, widely used in industry, the use of only steelAluminum Alloy divided into two categories: cast Aluminum Alloy, cast under; deformation Aluminum Alloy, can withstand the pressure processing, mechanical properties than cast. Aluminum Alloy material can be processed into various forms and specifications. Mainly used in the manufacture of aviation equipment, daily necessities, building doors and windows.

- Q: Will the enterprises that produce sponge titanium use magnesium ingots?

- In the process of reduction, trace impurities in TiCl4 such as AlCl3, FeCl3, SiCl4 and VOCl3 are reduced by magnesium to form corresponding metals. These metals are all mixed with sponge titanium. Impurities such as potassium, calcium and sodium, which are mixed with magnesium, are also reducing agents. They reduce TiCl4 and produce the corresponding impurity chlorides respectively. Magnesium reduction process includes: TiCl4 liquid, gas and liquid gasification TiCl4 Mg diffusion of TiCl4 and Mg molecules adsorbed on the active center, in the active center of chemical reaction, nucleation, crystal growth, titanium MgCl2 desorption, diffusion MgCl2. The key step in this process is crystallization nucleation, accompanied by heterogeneous nucleation with chemical reactions.

- Q: What is magnesium aluminum alloy and what is its use?

- Magnesium ingot and aluminium in the above 1150K, reaction of aluminum and oxygen in the air to form a-Al2O3, the crystal chemical properties of alumina is inert, a barrier and isolation. Less than 1150K, in the B-Al2O3 and the crystal reaction with acid magnesium alloy not inner protection.

Send your message to us

Magnesium Alloy Ingot with Shortest Delivery Time

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords