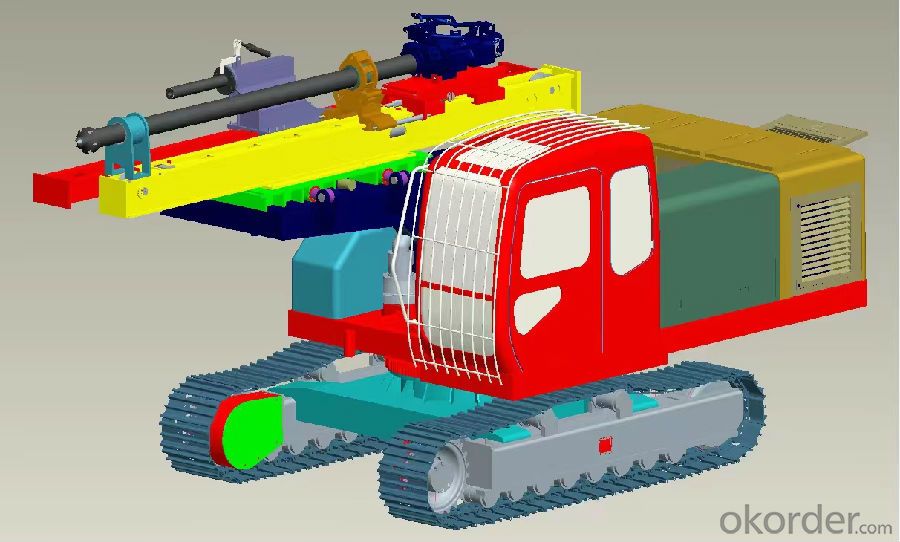

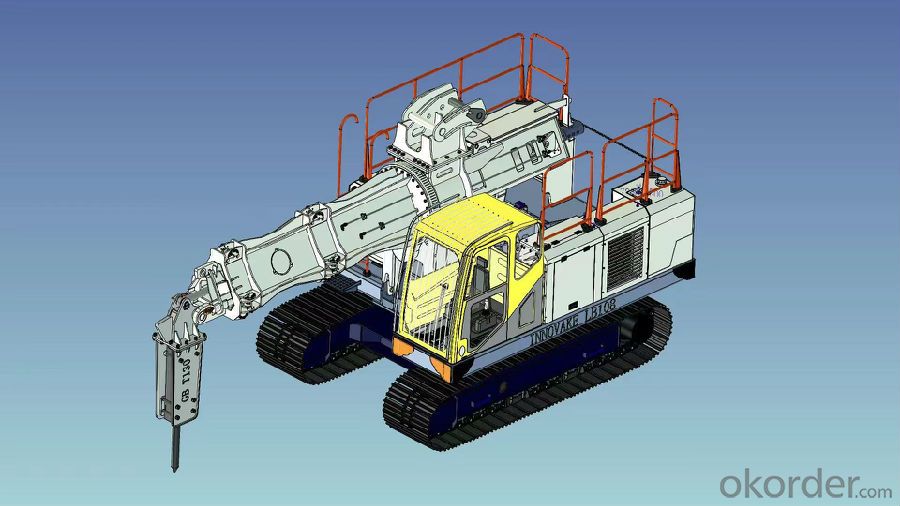

Ladel Debricking/Reaming Machine Reamer for Converter and BOF

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 9999 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM metallurgic equipments, such as Ladel Debricking Machine, Reamer for Converter and BOF, Slag Removing Machine, Hot spraying machine for BOF and related drilling parts

In order to guaranty better usage of your Refractory wrecking machine produced by CNBM minimize the failure rate of the engine, we hope and advise you to operate strictly according to the engine operation and maintenance instruction. Since the operation environment is comparably harsh, inspection and changing of the air/fuel/oil filter’s cartridges timely are strongly required. Here after we advise you to notice the inspection and supplement of water tank antifreeze.

Checking the height of the exhaust valve switch of the engine top water room after the engine stop running and the water temperature approach normal temperature.

b. Open the water tank cover (this operation is forbidden at high temperature to avoid any accident )

c. check whether the water tank is full filled. Especially the water tank with the interlayer. Insert a ruler or clean antifreeze (coolant) with the same spec. we use the antifreeze of BLUE STAR -40°C. Please fill the antifreeze slowly until full filled. To the water tank with interlayer, the filling course is slower, and need to wait until the antifreeze surface is not descending ( this will need around 20 minutes) to make sure the water tank is full. To accelerate the filling speed, you need to disconnect the drainage mouth from the engine, fill from drainage mouth until overflowing and then reconnect it with the engine, and then you need to fill from the water tank cover until full.

e. The last step goes back to item a, turn off the exhaust valve switch on the top water room of the engine and cover the water tank.

f. Please wait until the antifreeze is totally discharged while changing it. The overall volume of the engine and water tank is approximately equal to the volume of 30KG liquid.

- Q: How to do well the maintenance and maintenance of metallurgical machinery equipment

- The main problem in the management of metallurgical machinery and equipment is not systematic. At this stage, the metallurgical industry in China has many new and old equipment mix and match phenomenon, the management is also relatively confusing. Mainly because many enterprises pay more attention to the economic benefits, and pay little attention to the maintenance and maintenance of metallurgical equipment. This leads to the low level of equipment management in the metallurgical industry, and may cause various equipment management problems, so that the service life of various equipment will be reduced, and enterprises will have to pay more economic costs.

- Q: Metallurgical mechanical blade

- The cutting edge hardness of the mechanical blade used for cutting metal is generally above 60HRC. Wear resistance is the ability of materials to resist wear. Generally speaking, the higher the hardness of mechanical blade material, the better its wear resistance.

- Q: What kind of products are metallurgical equipment in iron and steel works?

- These are the main, there are many, can be broadly divided into several categories: steel hydraulic devices, steel machinery, steel mills, electrical automation equipment.

Send your message to us

Ladel Debricking/Reaming Machine Reamer for Converter and BOF

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 9999 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches