Inorganic exterior wall coating Exterior wall coating Inorganic coating wholesale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 90000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

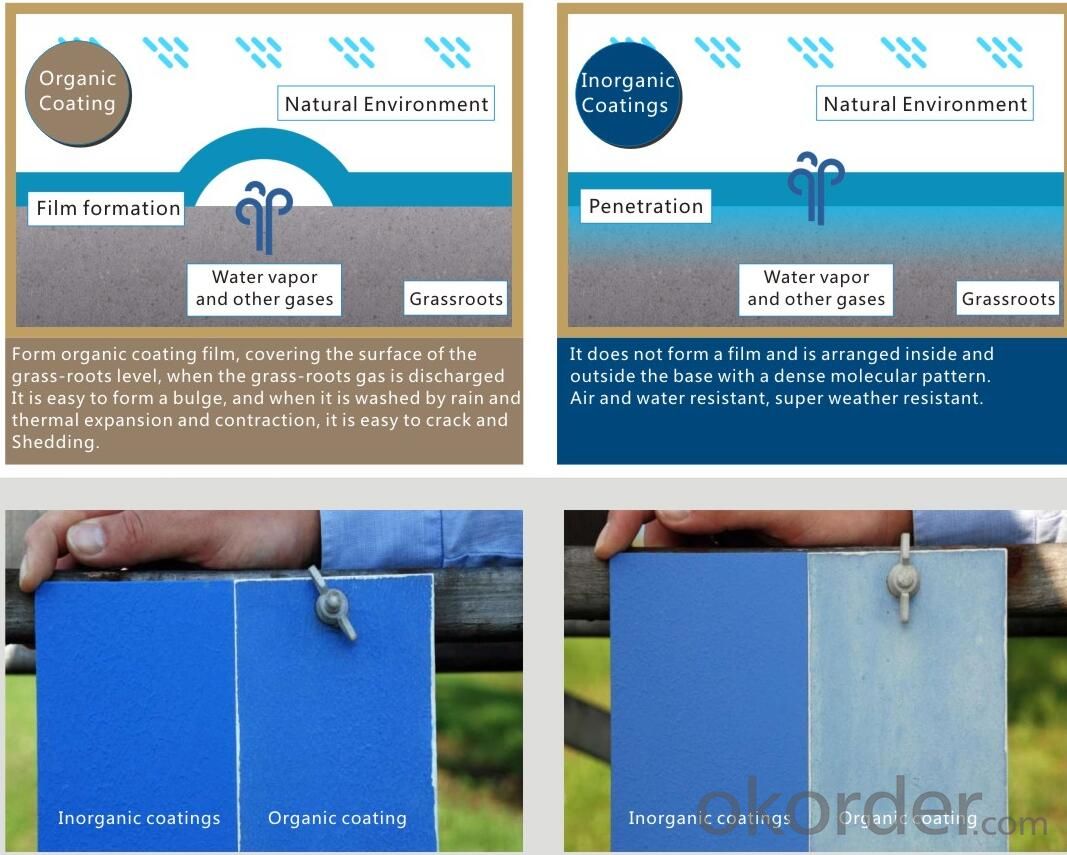

Exterior wall inorganic building coating is the alkali metal silicate and silicon sol as the main binder, using the method of brushing, spraying or roll coating, forming a thin decorative coating on the building, made by the professional team research and development formula, does not contain formaldehyde, volatile organic compounds, heavy metals and other harmful substances.

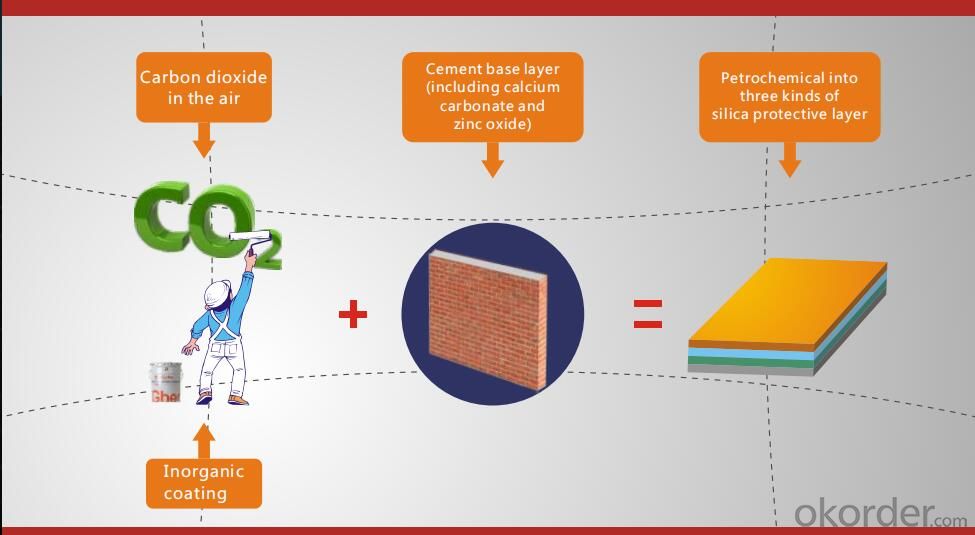

Water-based inorganic coating is a water-based architectural and decorative coating based on pure natural inorganic mineral raw materials, whose main component is oxidized modified potassium silicate and the product structure is a reticulated multi-sphere molecular combination. The inorganic components in the coating and the inorganic substances in the substrate undergo chemical reaction to form new inorganic substances, which are integrated with the substrate and not easy to fall off. The modified potassium silicate is compatible with various inorganic pigments, which not only keeps the original color but also plays a curing role and makes the coating film less likely to fade. Based on the above principles, it contributes to the natural environmental protection, fire retardant, aging resistance and super weather resistance of water-based inorganic coatings.

The reaction principle of inorganic mineral coatings

Product Characteristics:

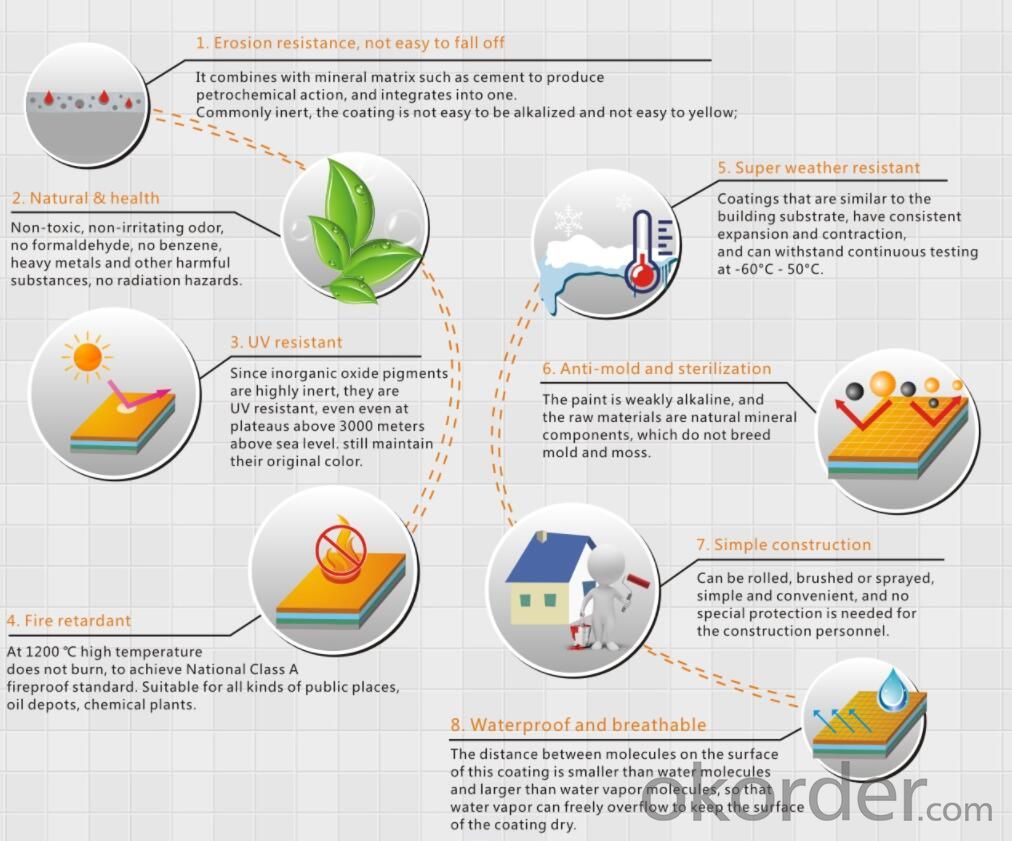

1. Inorganic coating is filled with mineral materials to form a breathable and petrification film. The film is long lasting and won't peel off so it saved any film stripping in the future maintainance. The film color is resistant to alkali or yellowing;

2. Non toxic, no pungent smell, no formaldehyde, benzene, heavy metals or other harmful substances, no radiation hazards;

3. Due to the inertia of inorganic oxide pigments, inorganic coating is UV resistant and natural color stable on the plateau of 3000 meters altitude;

4. Fire proof and flame retardancy: The coating is smoke free. The flammable point of the mineral materials used in the coating is up to 1200 ℃, qualifying for the A1 GB national standard of fire retardation. Thus the coating is suitable for all types of public places, oil depots and chemical plants where fire proof is a top concern;

5. After chemical reaction, Gber inorganic coating forms a petrification film with the substrat. The film expands and shrinks freely and can withstand the continuous test at a range of minus 60 ℃ - 50 ℃;

6. Mildew and sterilization do not breed moss. Gber inorganic mineral coating is of weakly alkaline. The raw natural mineral composition don't breed mold or moss;

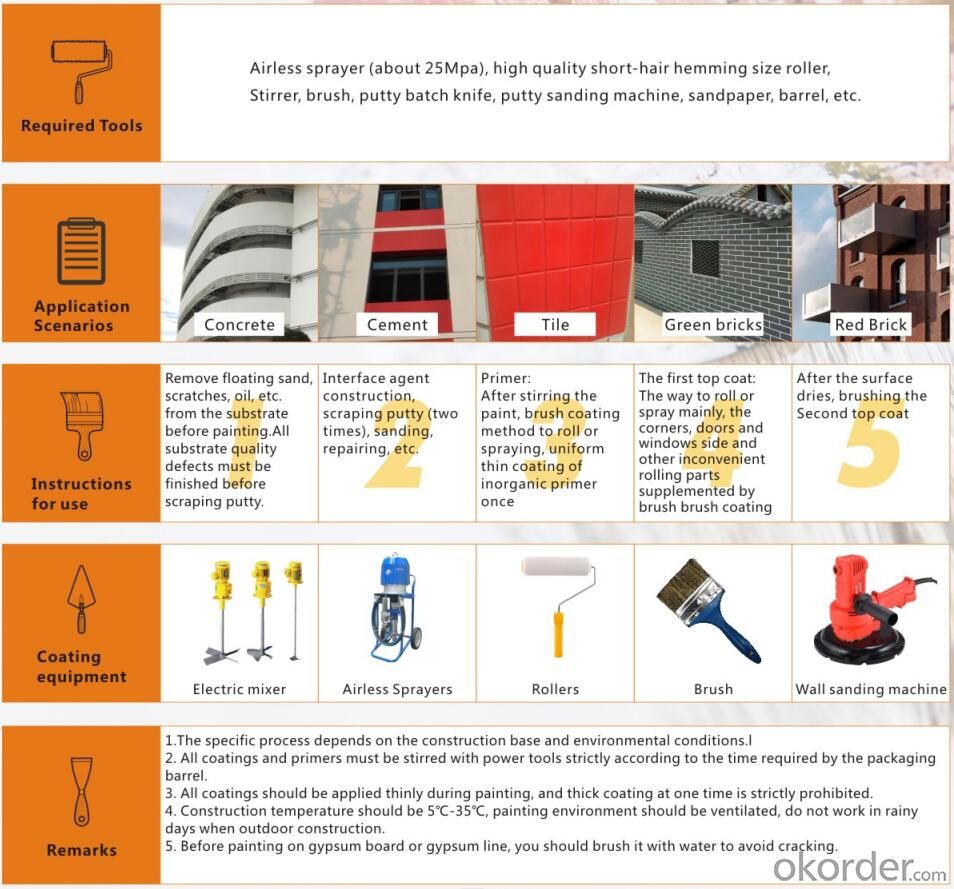

7. The coating application is simple. It can be rolled, brushed or sprayed. The applicator doesn't require special protection at the construction sites;

8. Inorganic coating is waterproof and breathable. It is not easy to crack or blister. The coating depots and penetrates into the wall and forms a common layer. The film surface matrix is smaller than that of the water molecules and greater than that of water vapor. So the film has the same one-way breathing performance as that of human skin: the water vapor can breath freely to keep the coating surface dry but water won't penetrate the film.

Product Research & Development Laboratory:

The company is a comprehensive high-tech enterprise integrating scientific research, production, sales and technical services, and it is one of the leading enterprises in the production of inorganic coatings in China. The company has independent research and development team, participate in the formulation of inorganic paint industry standards, both production scale and market share are in the forefront of the country. Factory workshop has an annual output of tens of thousands of tons of water inorganic mineral coating production line, and supporting research and development testing center, office conference room, staff rooms, etc, the factory through the third party environmental impact assessment, advanced manufacturing equipment machine, perfect living facilities, the factory production environment, or enterprise staff living environment, has reached the relevant national and local government of environmental protection, energy conservation and safety regulations and standards.

With the enhancement of consumer environmental protection and health concept, the development of environmental protection of inorganic paint products will become the development trend of China and even the world paint industry.

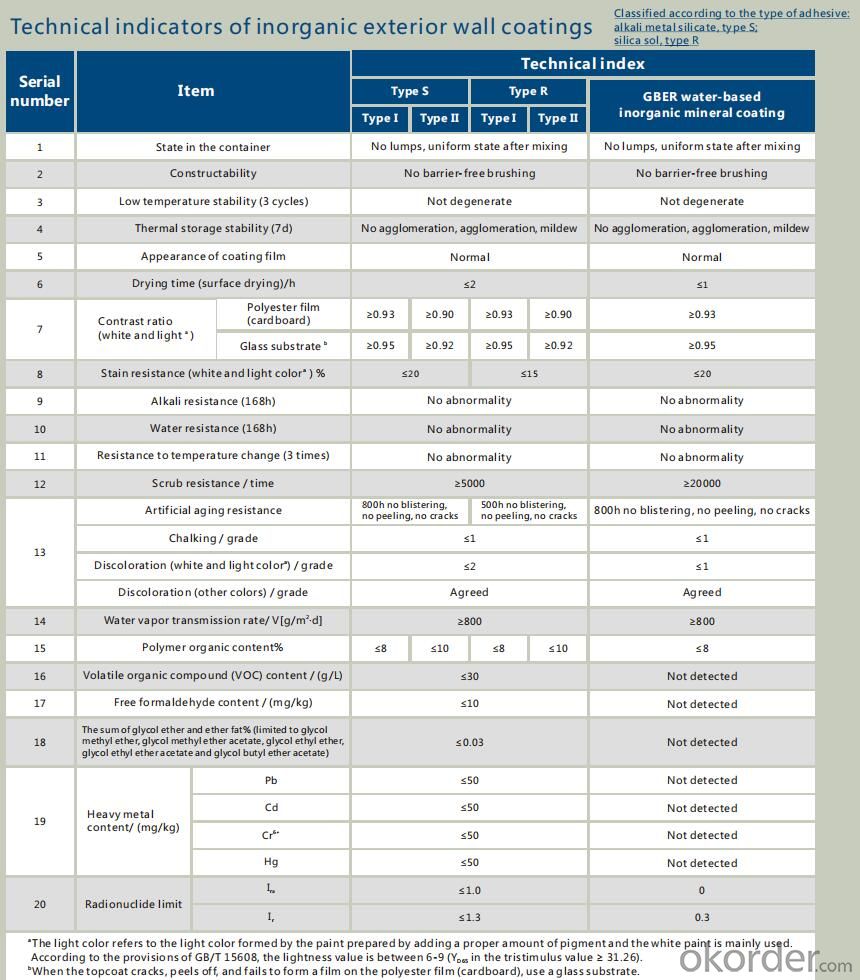

Product Specifications and Parameters:

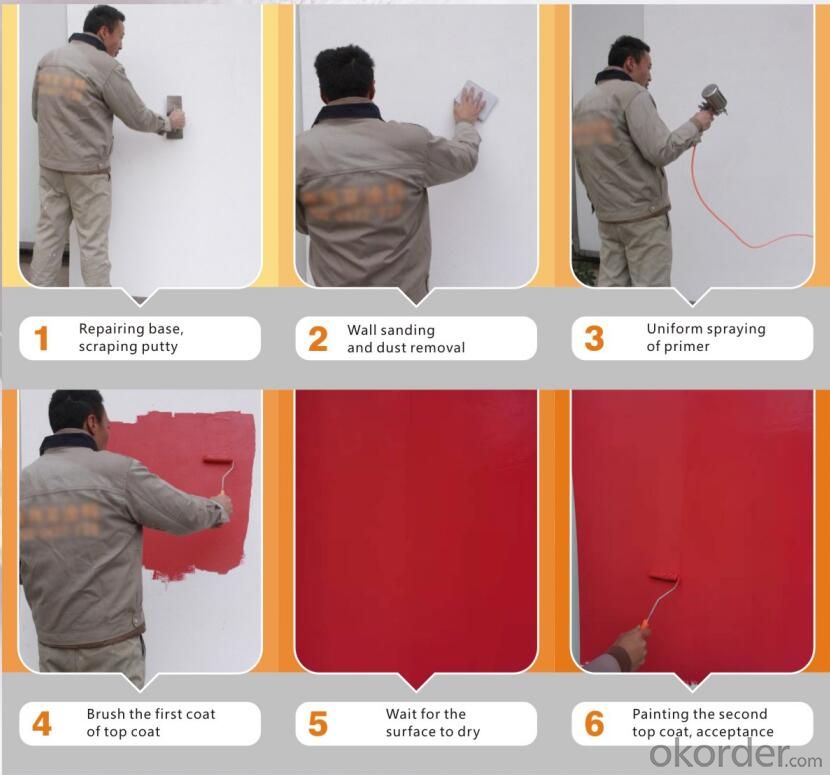

Product construction steps:

Product application cases:

FAQ:

Q1 Why is the inorganic paint resistant to salt spray?

A1 Combined with cement and other mineral matrix, petrochemical effect, integrated, common inert, coating is not easy to pan-alkali, not easy to yellowing;

Q2 Why does inorganic paint not breed moss?

A2 Waterborne inorganic mineral coating is weakly alkaline, and the raw material is a natural mineral composition, does not breed mold, moss.

Q3 Why is the inorganic coating weather-resistant?

A3 After the petrochemical reaction of inorganic coating is similar to the building matrix, the expansion and shrinkage are consistent, and can withstand the continuous test of minus 60℃ -50℃;

- Q: Is the polymer cement - based waterproof coating required for inspection?

- Waterproof paint approach sampling inspection:

- Q: How much is a kilogram of paint

- Ranging from a few dollars to a few hundred dollars, to see what you want quality

- Q: which horse breed is better in your opinion paints or mustangs?

- neither. Paints are frequently bred only for color, so they typically have bad dispositions, and are either mean or skitso. Mustangs are good and hardy for trails, but they don't have the elegance of a line-bred breed. If you're wanting just a good trail horse, mustangs are great, but they just don't (as a breed, there are always exceptions) have the speed of a QH, the jumping abilities of a TB or warmblood, the fluid show style of an Andalusian, or the energy of an Arabian.

- Q: Clothes stick to the paint and acrylic paint how can we wash ah?

- On the lighter color of the machine grease, can be used to scrub the gasoline, and then in the clothing oil up and down the pad of a blotter paper or cloth, ironing with iron, so that the oil further evaporates, absorbed by paper or cloth, Cloth repeatedly ironing until the oil all were exhausted. Finally washed with detergent, and then rinse with water. On the darker color of the machine must be rinsed with high-quality gasoline, and then use the blotter paper or cloth ironing absorption, and finally rinse with warm water.

- Q: Is the paint good for 5 kg or 9 kg?

- 9 kg more cost-effective quality is not much difference between the packaging is certainly affordable!

- Q: Polymer batteries and 18650 batteries in the end which is more secure?

- The polymer cell is also an integral part of a lithium-ion battery. Lithium ion secondary rechargeable battery is composed of this: batteries + protection circuit board. Rechargeable battery removal protection circuit board is the battery. He is the battery part of the rechargeable battery. The quality of the battery directly determines the quality of the rechargeable battery.

- Q: The most fundamental difference between dyes and pigments

- Pigment is oil-soluble, there is no soluble ionic groups, in the water can only show a dispersed state, can not dissolve. Can not be used directly to dye textile fibers, the most commonly used as paint, paint, paint the pigment.

- Q: How are automotive paint differ from building paints?

- I am in the process of painting my house and I am painting and restoring a fiberglass car. Most exterior house paint is latex and water based. It is a one part process, you dump it in the bucket and paint it on the building. Automotive paint is different. House paint needs to be able to give a little. not so much on a car. adhesion is an issue too. modern automotive paint is applied in two parts. base color coat which is the color mixed with a reducer Clear coat which is mixed with a hardener. the clear is what adds the depth and protection to your paint job. by building up the clear when you paint a car, you are able to color sand or sand it down with very fine sand paper. this smooth clear is what makes it have that mirror shine. building paints wont shine or buff out like that.

- Q: Paint composition and manufacturing process

- Paint mainly consists of four parts: film-forming substances, pigments, solvents, additives.

- Q: Is the paint and the paste the same thing?

- The color paste is not a paint, but a pigment paste, used to paint the paint, that is, one of the components of the paint

Send your message to us

Inorganic exterior wall coating Exterior wall coating Inorganic coating wholesale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 90000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches