High temperature Type 1 Coe 5.0 glass tubing round heat resistant glass tubes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1600 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High temperature Type 1 Coe 5.0 glass tubing round heat resistant glass tubes

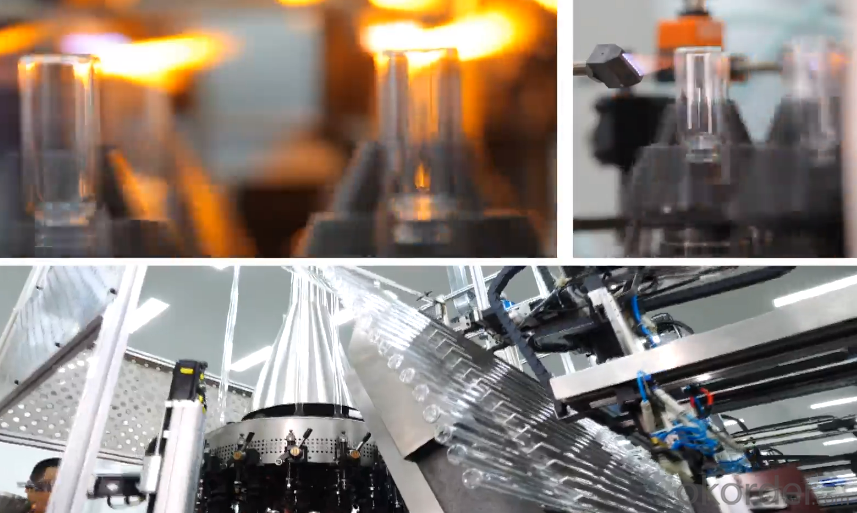

Neutral Pharmaceutical Glass Tube commonly refers to tubes made from neutral borosilicate glass with a coefficient of mean linear thermal expansion of 5.0. Generally, it has exceptional chemical stability and high heat resistance to thermal shock and sudden temperature change. It is typically used as a raw material by the pharmaceutical packaging companies to manufacture primary packaging products and plays a major role in the manufacturing process of pharmaceutical parental containers.

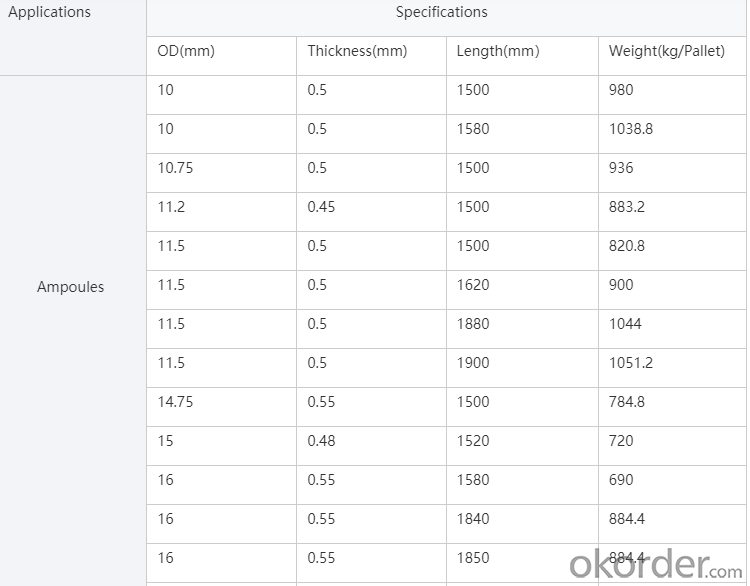

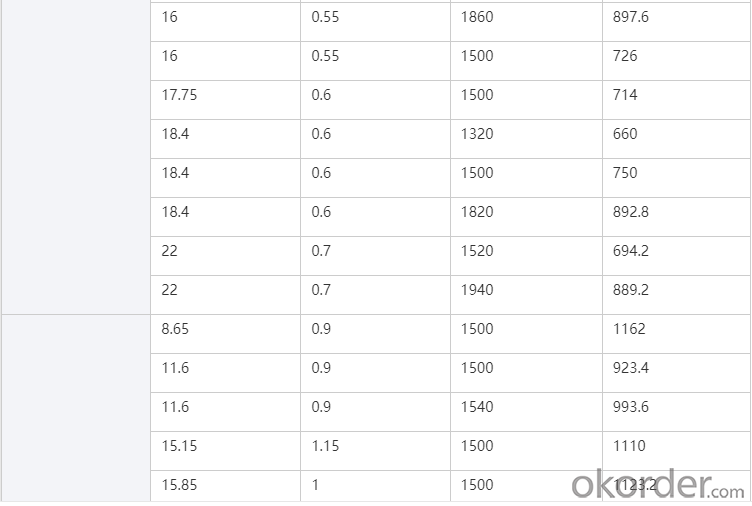

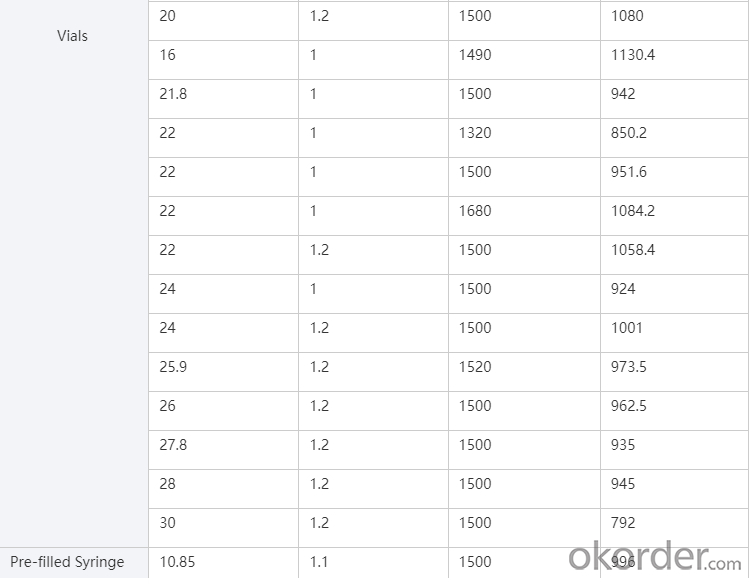

Specifications

Company Profile

CNBM Group, one of the Fortune Global 500 enterprises in the world. With our efforts to develop the market domestic and abroad, we have built cooperation and partnership with 1600 manufacturers in China, and have established stable business relationship in more than 120 countries and regions abroad. CNBM International Corporation is an important member of the Logistics Trade Section of CNBM Group provides complete range of materials products, including decorative materials, insulation materials, waterproofing materials, refractories, fiberglass products,glass etc. Our exportation volume of fiberglass roving and strands is listed top 3 among the export traders in China.It integrates R&D,manufacturing and circulation.Our neutral botocilicate glass factory is specialized in designing ,research,macnufacturing and trading of USP Type I neutral borocilicate glass tubes and bottles.We has been tested by the National Inspection Agency-Beijing Drug Packaging Test Institute.It is fully complies with the stabdards of EP,USP,JP,ISO12775 and the standard of YBB00012005-2-2015 ect.It has reached the international evel in expansion coefficient,content of boron of boron and hydrolitic resistane and other performance index ,it can help the socity for drug safty and healthy life.

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Delivery:Rush Order in 7-10 days for small order,10-30 days for bulk order

FRQ

1) Can we get your free samples?

Yes, you can. Our Samples are only free for the customers who confirm order. But the freight for express is

on buyer's account.

2) Can we combine many items size in one container in my first order?

Yes, you can. But the quantity of each ordered item should reach our MOQ.

3) What is the normal lead time ?

A. We will send goods to you within 15-35 work days after we receive your 30% deposit.The detail is based on the current

production schedule.

4) What is your shipping way?

We will help you to choose the best shipping way according to your detail requirements.

By sea, by air, or by express, etc.

5) How do you control the quality?

We will make samples before mass production, and after sample approved, we will begin mass production.

Doing 100% inspection during production; then do random inspection

before packing; taking pictures after packing.

6) If any quality problem, how can you settle it for us?

If any breakage or defect products were found, you must take the pictures from the

original carton. All the claims must be presented within 7 working days after discharging

the container. This date is subject to the arrival time of container.

We will advise you to certify the claim by third party, or we can accept the claim from the

samples or pictures you present, finally we will completely compensate all your loss.

- Q: What's the color strip in the tail of a cosmetic tube?

- Is the magic eye location, is used for positioning and recognition in the production of cosmetics products and sealing the electric eye positioning function is very common in printing packaging hose, hose product is produced after the completion of automatic filling and sealing machine location application.

- Q: What are the disposable medical plastic bags made of?

- Shrink film (Shrinkfilm) is a thermoplastic film that is stretched in production, directed, and contracted by hot air treatment or infrared radiation during use. After heat treatment, the film is wrapped tightly in the package, and the shrinkage force reaches the maximum value in the cooling stage and can be stored for a long time.

- Q: Accidentally put all the skin care products squeezed out, the kind of tubular packaging, and then I promptly put the skin care products sucked back, can I ask skin care products can still use it?

- This is also a lot of identity, it used in the face of things, try to pay attention to it, really spent, not money can cure the cream tube. Keep it as a hand cream.

- Q: CLARINS body shaping cream is bottle shaped or tubular packaging

- Maybe it has been changed. It's normal to change the packing, too. It's convenient to use tubular. Or go to the counter to see it, look at the counter, what is the sale now?

- Q: What's the advantage of plastic packing?

- ) small proportion, light weight. Although the proportion is less than that of other plastic packaging materials, but their strength / weight ratio is larger, making it possible to replace some larger strength materials, packaging container for manufacturing large load-bearing (such as a barrel, basket and box etc.). Packing materials and containers are small in proportion, which can save handling and transportation costs.

- Q: What kind of material are plastic bags made of?

- PVC-- polyvinyl chloride PVC referred to as PVC, the molecular formula for (CH2 - CH2CL) n, is the most important category of vinyl polymers, is currently the world's second largest plastic varieties after polyethylene. In China, the yield is the first in plastics. In the printing industry, packaging production of books, folders, tickets and other frequently used PVC calendered film cover color and transparent glazing film.

Send your message to us

High temperature Type 1 Coe 5.0 glass tubing round heat resistant glass tubes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1600 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords